Preparation method for high-efficiency soy protein frothing agent

A technology of soybean protein and soybean protein isolate, which is applied in the transformation of soybean protein structure and functional properties, and the preparation of high-efficiency soybean protein foaming agent, can solve the problems that the foaming ability and foam stability have not been significantly improved at the same time, Achieve the effects of promoting agricultural economic development, broadening applications, improving foaming and foam stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Accurately weigh 40g of soy protein isolate, add water and stir to dissolve, prepare 8% (w / v) protein solution, adjust the pH to 8.0 with 1mol / L NaOH solution, keep the temperature at 55℃, add alkaline protease Alcalase (0.2 %, v / v) for the hydrolysis reaction (while maintaining the pH value of the protein solution at 8.0). When the degree of protein hydrolysis reaches 3%, the reaction is terminated. The hydrolyzed solution is heated in a boiling water bath for 15 minutes to inactivate the enzyme, and centrifuged (5000r / min, 20min ) Then collect the supernatant.

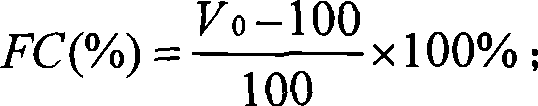

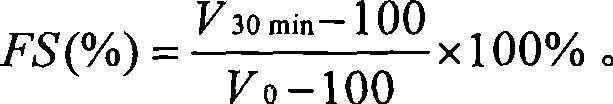

[0025] Use a polysulfone ultrafiltration membrane with a molecular weight cut-off of 10kDa to ultrafilter the soy protein hydrolysate with a protein hydrolysis degree of 3%, collect the cut-off part, and obtain protein peptides with a molecular weight greater than 10kDa. The foaming ability of this part of the protein is measured as 165.6%, an increase of 250% compared with soy protein isolate (47.3%), and the foa...

Embodiment 2

[0028] Accurately weigh 50g of soy protein isolate, add water and stir to dissolve, prepare 8% (w / v) protein solution, adjust the pH to 8.0 with 1mol / L NaOH solution, keep the temperature at 55℃, add alkaline protease Alcalase (0.2 %, v / v) for the hydrolysis reaction (while maintaining the pH value of the protein solution at 8.0). When the degree of protein hydrolysis reaches 3%, the reaction is terminated. The hydrolyzed solution is heated in a boiling water bath for 15 minutes to inactivate the enzyme, and centrifuged (5000r / min, 20min ) Then collect the supernatant.

[0029] Use a polysulfone ultrafiltration membrane with a molecular weight cut-off of 10kDa to ultrafilter the soy protein hydrolysate with a protein hydrolysis degree of 3%, collect the cut-off part, and obtain protein peptides with a molecular weight greater than 10kDa. The foaming ability of this part of the protein is measured as 175%, compared with soy protein isolate (47.3%), an increase of 270%, while foam s...

Embodiment 3

[0032] Accurately weigh 50g of soy protein isolate, add water and stir to dissolve, prepare 8% (w / v) protein solution, adjust the pH value to 8.0 with 1mol / L NaOH solution, keep the temperature at 55℃, add alkaline protease Alcalase (0.2 %, v / v) for the hydrolysis reaction (the pH of the protein solution is maintained at 8.0 during the period). When the degree of protein hydrolysis reaches 3%, the reaction is terminated. The hydrolyzed solution is heated in a boiling water bath for 15 minutes to inactivate the enzyme, and centrifuged (5000r / min, 20min ) Then collect the supernatant.

[0033] Use a polysulfone ultrafiltration membrane with a molecular weight cut-off of 10kDa to ultrafilter the soy protein hydrolysate with a protein hydrolysis degree of 3%, collect the cut-off part, and obtain protein peptides with a molecular weight greater than 10kDa. The foaming ability of this part of the protein is measured as 172.6%, compared with soy protein isolate (47.3%), increased by 265%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com