Catalyst for preparing epoxypropane with propylene gas-phase epoxidation and preparation method thereof

A technology of propylene oxide and catalyst, which is applied in the field of catalyst for producing propylene oxide and its preparation, and can solve the problems of industrialization gap and low selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1: According to the molar ratio of tetraethoxysilane: tetra-n-butyl titanate: ethanol: isopropanol: dodecylamine: water: hydrogen chloride=1: 0.05: 6.5: 1: 0.027: 36: 0.02, in order Take tetraethoxysilane, tetra-n-butyl titanate, ethanol and isopropanol and stir and mix uniformly to obtain solution A. Then dodecylamine was dissolved in 0.01-0.05 mol / L HCl aqueous solution to obtain solution B. Solution A was gradually added dropwise to solution B, then stirred for 0.5 h, and aged at 20° C. for 24 h. The resulting material was washed with deionized water and vacuum-dried at 60° C. overnight, and then calcined at 650° C. for 5 h to obtain the carrier Ti-HMS.

[0024]Take 10.4 mL of chloroauric acid aqueous solution with a concentration of 0.01 mol / L, add 50 mL of deionized water to dilute, adjust the pH value of the solution to 7.0, add 0.5 g of the Ti-HMS carrier prepared above, and keep the pH value of the solution at 7.0. After stirring at ℃ for 1.5h, suction...

Embodiment 2~5

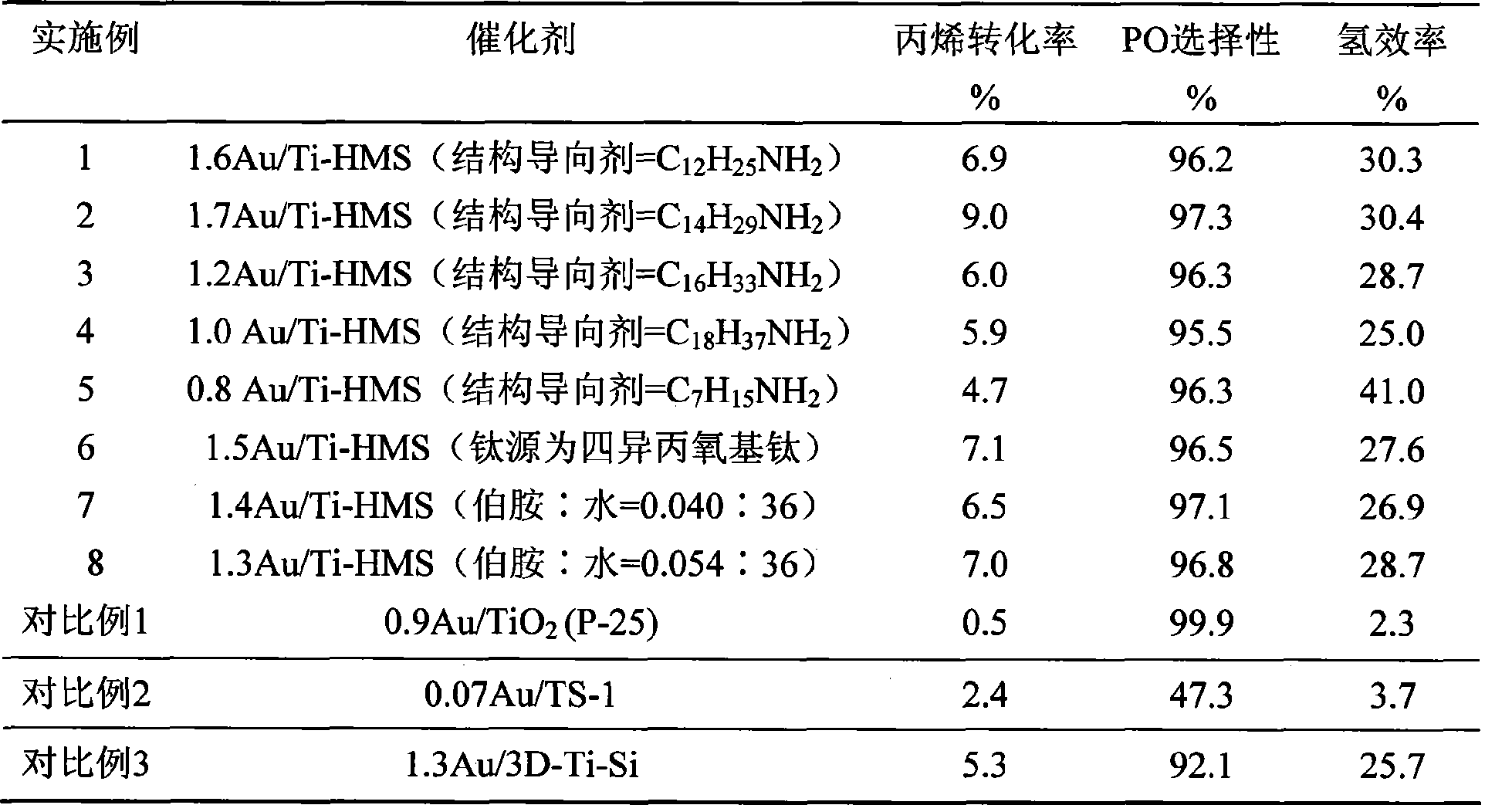

[0026] Examples 2 to 5: Catalyst system as in Example 1, but in the preparation of Ti-HMS carrier, examples 2 to 5 use tetradecylamine, hexadecylamine, octadecylamine, and heptylamine as structure-directing agents, and the chemical composition 1.7Au / Ti-HMS, 1.2Au / Ti-HMS, 1.0Au / Ti-HMS, 0.8Au / Ti-HMS respectively, other reaction conditions are the same as in Example 1. The results of the catalytic reactions are shown in Table 1.

Embodiment 6

[0027] Embodiment 6: Press tetraethoxysilane: tetraisopropoxytitanium: ethanol: isopropanol: dodecylamine: water: hydrogen chloride=1: 0.05: 6.5: 1: 0.027: 36: 0.02, in order Take tetraethoxysilane, tetraisopropoxytitanium, ethanol and isopropanol and stir and mix uniformly to obtain solution A. Then dodecylamine was dissolved in 0.005-0.008 mol / L HCl aqueous solution to obtain solution B. Solution A was gradually added dropwise to solution B, then stirred for 0.5 h, and aged at 40° C. for 15 h. The resulting material was washed with deionized water and vacuum-dried at 50° C. overnight, and then calcined at 550° C. for 6 h to obtain the carrier Ti-HMS.

[0028] Take 10.4 mL of chloroauric acid aqueous solution with a concentration of 0.01 mol / L, add 50 mL of deionized water to dilute, adjust the pH value of the solution to 7.0, add 0.5 g of the Ti-HMS carrier prepared above, and keep the pH value of the solution at 7.0. After stirring at ℃ for 1 h, suction filtration and was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com