High-strength bridge steel-gas protective welding method

A protection welding, high-strength technology, applied in the direction of welding equipment, arc welding equipment, workpiece edge, etc., can solve the problems that hinder the promotion and application of bridge steel and new steel types, and achieve excellent welding process performance, easy operation, and excellent low temperature The effect of impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

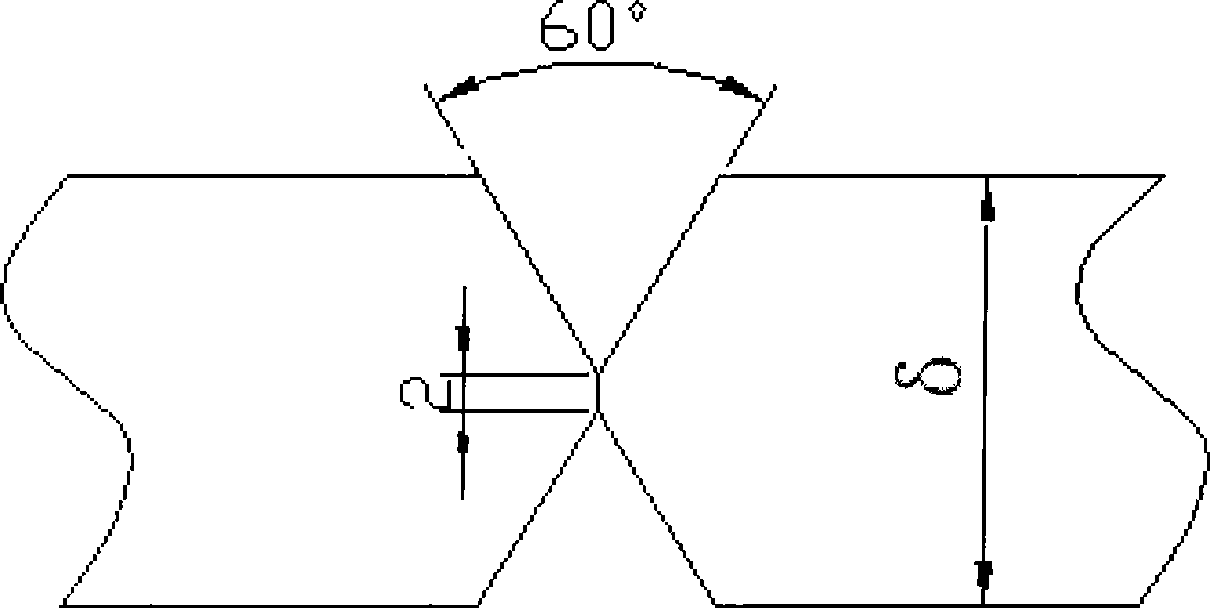

[0019] Base material: steel plate produced by thermomechanical controlled rolling process (TMCP) + tempering, thick plate combination 50mm+50mm; the mechanical properties of the steel plate with a thickness of 50mm are: yield strength R eL : 510MPa, tensile strength R m :645MPa, elongation rate A: 21%, impact energy A at -40°C KV :180J. The size of the test plate is 600mm×400mm×50mm, and the gas shielded welding groove adopts a double-sided V-shaped symmetric groove. The groove size is shown in figure 1 As shown, the bevel angle is 60° and the blunt edge is 2mm.

[0020] Welding material matching:

[0021] Matching welding material: The chemical composition and weight percentage of the welding wire are: C: 0.04, Si: 0.07, Mn: 1.60, Ni: 0.60, Ti: 0.11, B: 0.004, P ≤ 0.015, S ≤ 0.010, the rest is iron And inevitable impurities. The diameter of the welding wire is Φ1.2mm.

[0022] Gas shielded butt welding of steel plates with a combination of 50mm+50mm thickness: its welding process...

Embodiment 2

[0025] Base material: steel plate produced by thermomechanical controlled rolling process (TMCP) + tempering, thick plate combination 50mm+50mm; the mechanical properties of the steel plate with a thickness of 50mm are: yield strength R eL : 530MPa, tensile strength R m :595MPa, elongation rate A: 21%, impact energy A at -40°C KV :205J. The size of the test plate is 600mm×400mm×50mm, and the gas shielded welding groove adopts a double-sided V-shaped symmetric groove. The groove size is shown in figure 1 As shown, the bevel angle is 60° and the blunt edge is 2mm.

[0026] Welding material matching:

[0027] Matching welding materials: The chemical composition and weight percentage of the welding wire are: C: 0.010, Si: 0.10, Mn: 1.80, Ni: 0.80, Ti: 0.17, B: 0.005, P ≤ 0.015, S ≤ 0.010, the rest is iron And inevitable impurities. The diameter of the welding wire is Φ1.2mm.

[0028] Gas shielded butt welding of steel plates with a combination of 50mm+50mm thickness: its welding proce...

Embodiment 3

[0032] Base material: steel plate produced by thermomechanical controlled rolling process (TMCP) + tempering, thick plate combination 50mm+50mm; the mechanical properties of the steel plate with a thickness of 50mm are: yield strength R eL : 540MPa, tensile strength R m : 635MPa, elongation rate A: 21%, impact energy A at -40°C KV :188J. The size of the test plate is 600mm×400mm×50mm, and the gas shielded welding groove adopts a double-sided V-shaped symmetric groove. The groove size is shown in figure 1 As shown, the bevel angle is 60° and the blunt edge is 2mm.

[0033] Welding material matching:

[0034] Matching welding materials: The chemical composition and weight percentage of the welding wire are: C: 0.08, Si: 0.07, Mn: 1.70, Ni: 0.70, Ti: 0.14, B: 0.007, P ≤ 0.015, S ≤ 0.010, the rest is iron And inevitable impurities. The diameter of the welding wire is Φ1.2mm.

[0035] Gas shielded butt welding of steel plates with a combination of 50mm+50mm thickness: its welding process...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com