Barrate type rubber fender

A kind of rubber fender and fender technology, which is applied in the direction of ship construction, ship, climate change adaptation, etc., can solve the problems that affect the berthing operation and safety, poor anti-collision force, difficult replacement and maintenance, etc., to beautify the port wharf, prevent Accidental impact, good protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

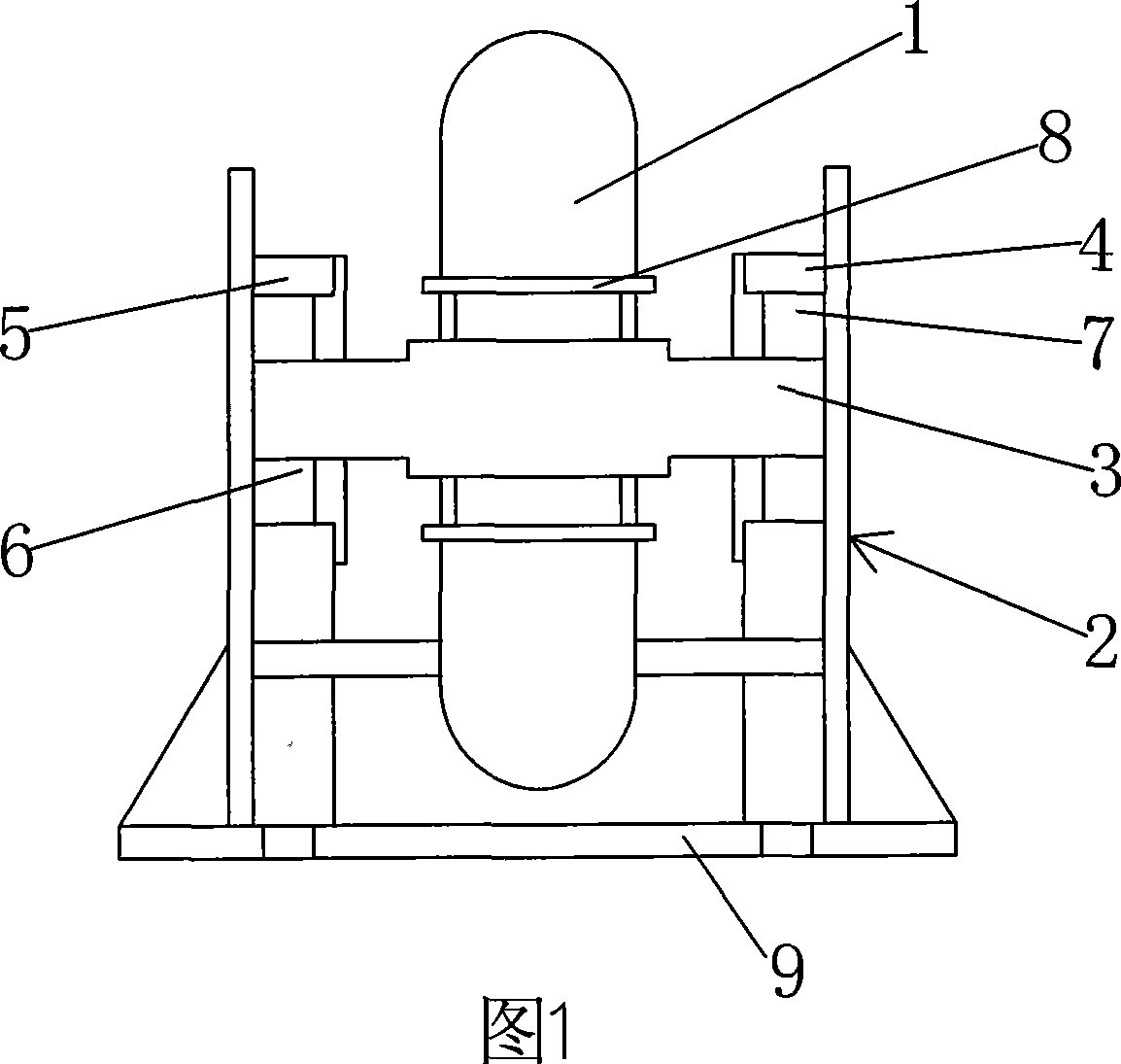

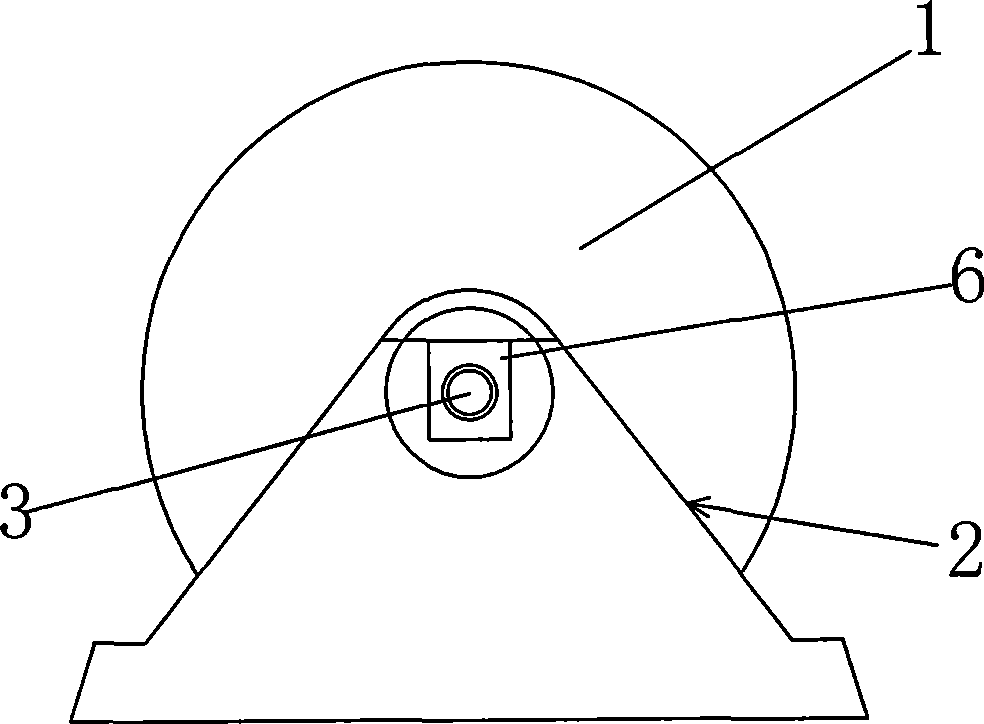

[0014] The drum type rubber fender includes a rubber fender wheel body 1, a wheel axle bracket 2 and a wheel axle 3. The two side walls of the axle bracket 2 are respectively and symmetrically provided with an axle seat 4 and an axle seat 5 , and a bearing bush 6 and a bearing bush 7 are respectively fixed in the axle holes of the axle seat 4 and the wheel seat 5 . The axle 3 passes through the drum 8 of the rubber fender wheel body 1, and the two ends of the axle 3 are respectively inserted into the bearing bush 6 and the bearing bush 7.

[0015] During use, the supporting plate 9 of the wheel axle bracket 2 is bolted to the set position on the ship and the wharf of the port.

Embodiment 2

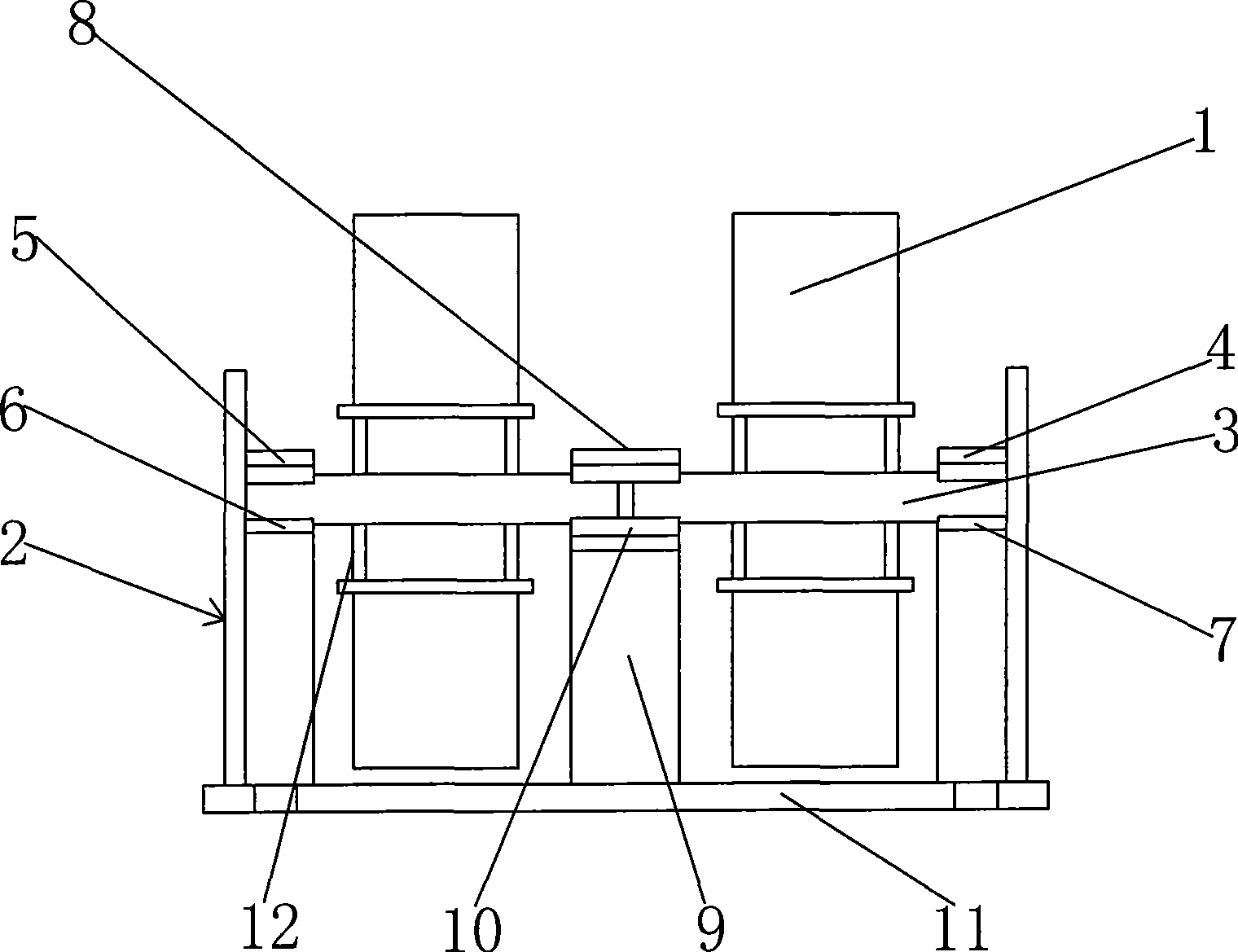

[0017] The drum type rubber fender includes two rubber fender wheel bodies 1, a wheel shaft 3 and a wheel shaft bracket 2.

[0018] The two sidewalls of the axle bracket 2 are provided with an axle seat 4 and an axle seat 5, and an axle seat 8 is arranged in the middle part of the wheel axle bracket 2, and the axle seat 8 is supported by a bracket 9, and the lower end of the bracket 9 is fixed on the wheel axle bracket 2. on pallet 11. Bearing bushes 6, 7, 10 are respectively fixed in the inner holes of the shaft seats 4, 5, and 8. The wheel shaft 3 passes through the wheel drum 12 of the first rubber fender wheel body 1, the bearing bush 10 in the inner hole of the shaft seat 8 and the wheel drum 12 of the second rubber fender wheel body 1, and the two ends of the wheel shaft 3 are respectively inserted into the shaft In the bearing bush 6 and the bearing bush 7 in the inner hole of the seat 4 and the shaft seat 5.

Embodiment 3

[0020] When the rubber fender wheel body 1 of the drum type rubber fender is made of rubber with colorful luminous effect, the rubber is made of natural rubber 15kg, styrene-butadiene rubber 15kg, butadiene rubber 18kg, polyurethane rubber 13kg, afterglow Luminescent powder (fluorescent agent) 2kg, reflective powder 6kg, zinc oxide 2.3kg, stearic acid 1.0kg, coumaron 0.4kg, light calcium carbonate 20kg, carbon black 28kg, pine tar 3kg, sulfur powder 1kg, accelerator DM0. 8kg, anti-aging agent RD0.6kg and toner 3kg are mixed evenly, molded and then vulcanized. Wherein mixing is a known technology.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com