Method for preparing ordered mesoporous carbon with organic mould plate method

A technology of ordered mesoporous carbon and organic template, applied in the field of ordered mesoporous carbon prepared by organic template method, can solve the problems of difficulty in maintaining ordered structure, easy collapse and destruction, small carbon pore size, etc. The effect of high rate, small volume shrinkage and collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

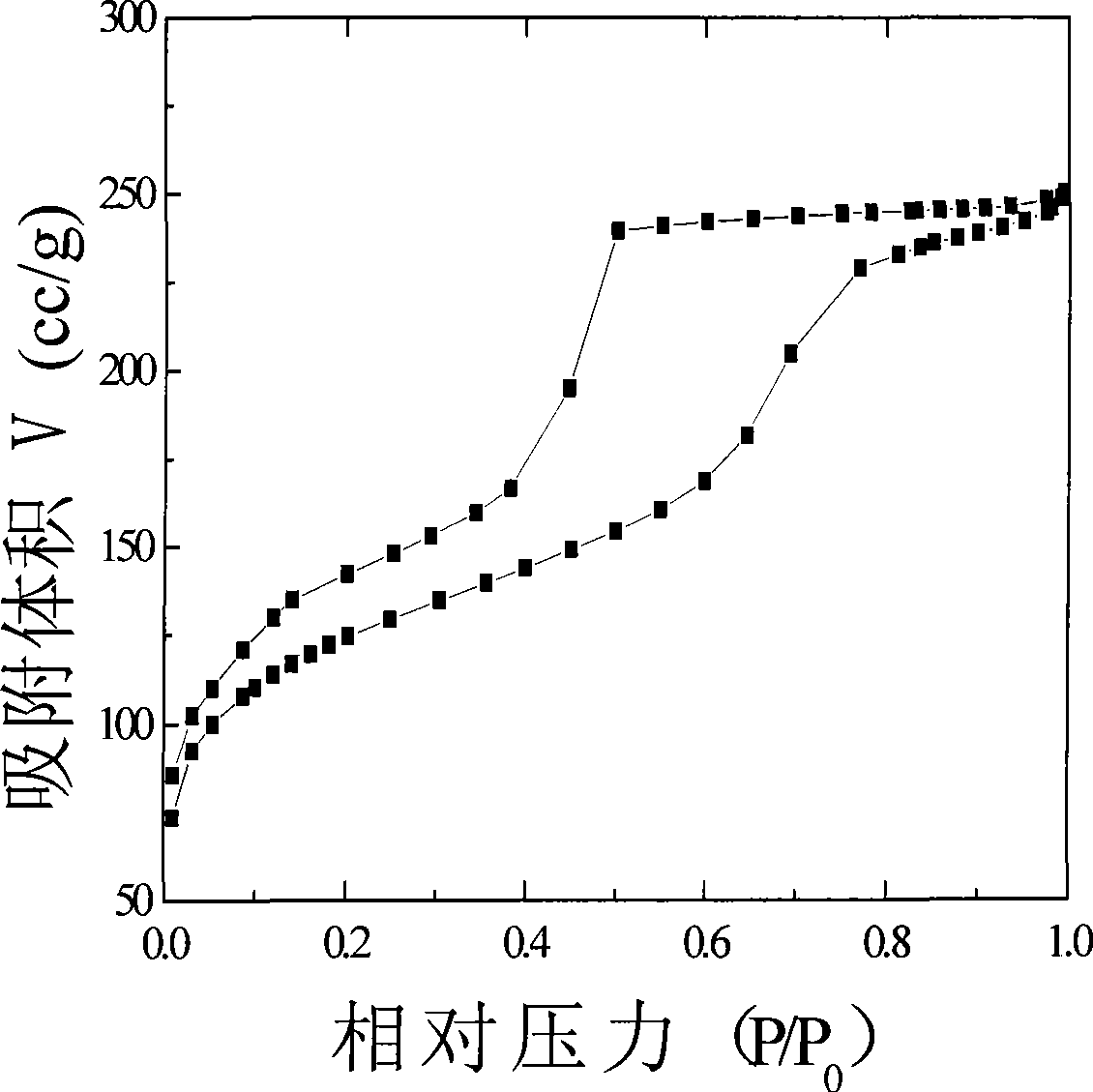

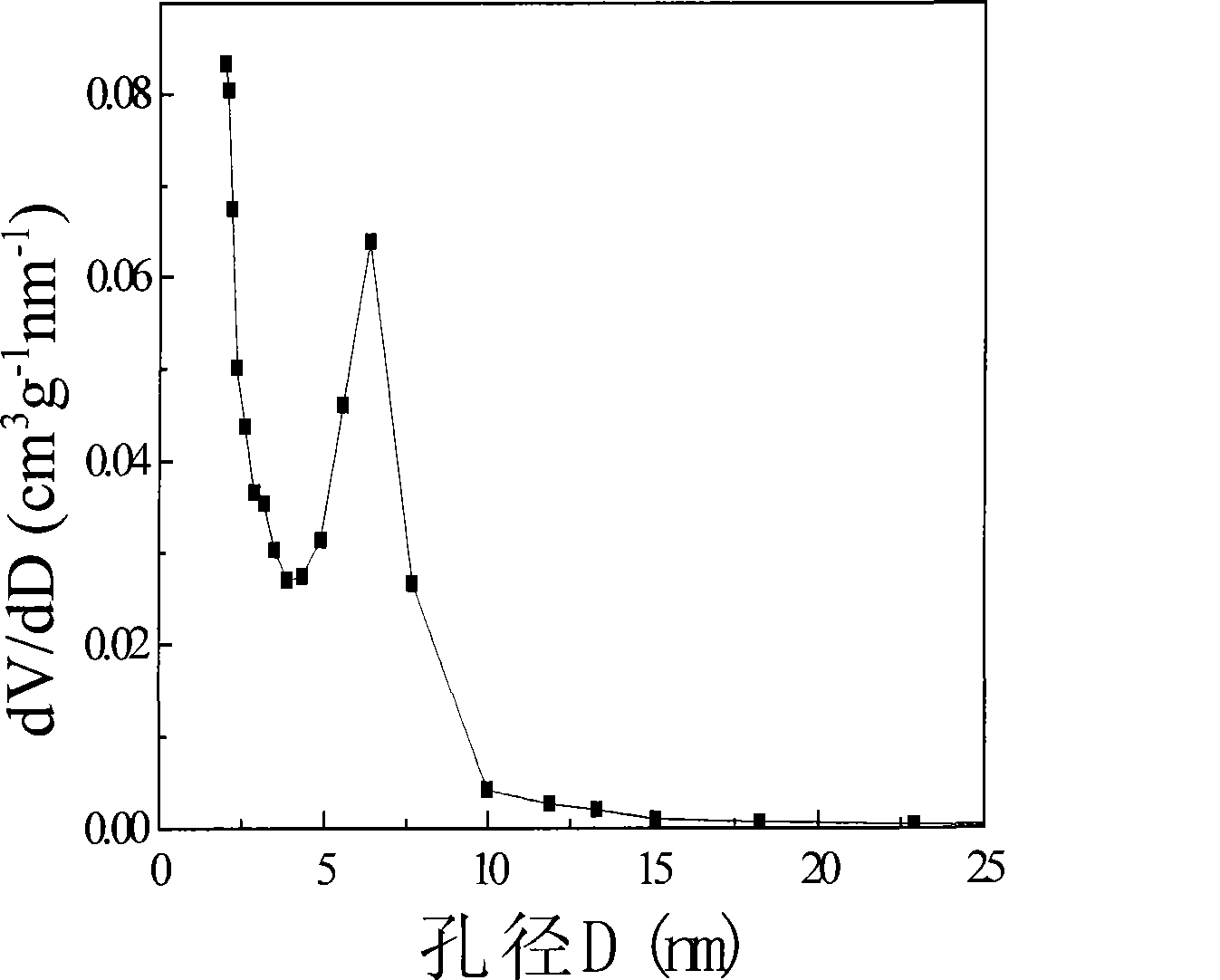

[0023] The steps for synthesizing ordered mesoporous carbon materials using resorcinol-formaldehyde resin as a carbon precursor, triblock copolymer F108 as a structure-directing agent, sodium hydroxide as a catalyst, and ethanol as a solvent are as follows:

[0024] Dissolve 2g of resorcinol in 20ml of ethanol, stir magnetically at room temperature, and after it is completely dissolved, add 4.4ml of formaldehyde solution with a mass fraction of 37% dropwise (the molar ratio of resorcinol to formaldehyde is 1:3 ), followed by the addition of 0.026 g of solid NaOH, and continued stirring for about 1 h. Dissolve 2.5g of F108 (the mass ratio of F108 to resorcinol is 2.5:2) in 20ml of ethanol, and magnetically stir it in a water bath at 30°C until it is completely dissolved, then add the above-mentioned ethanol solution containing resorcinol and formaldehyde , After mixing, stir in a water bath for 1.5h to form a light reddish brown homogeneous solution. The measured pH value of t...

Embodiment 2

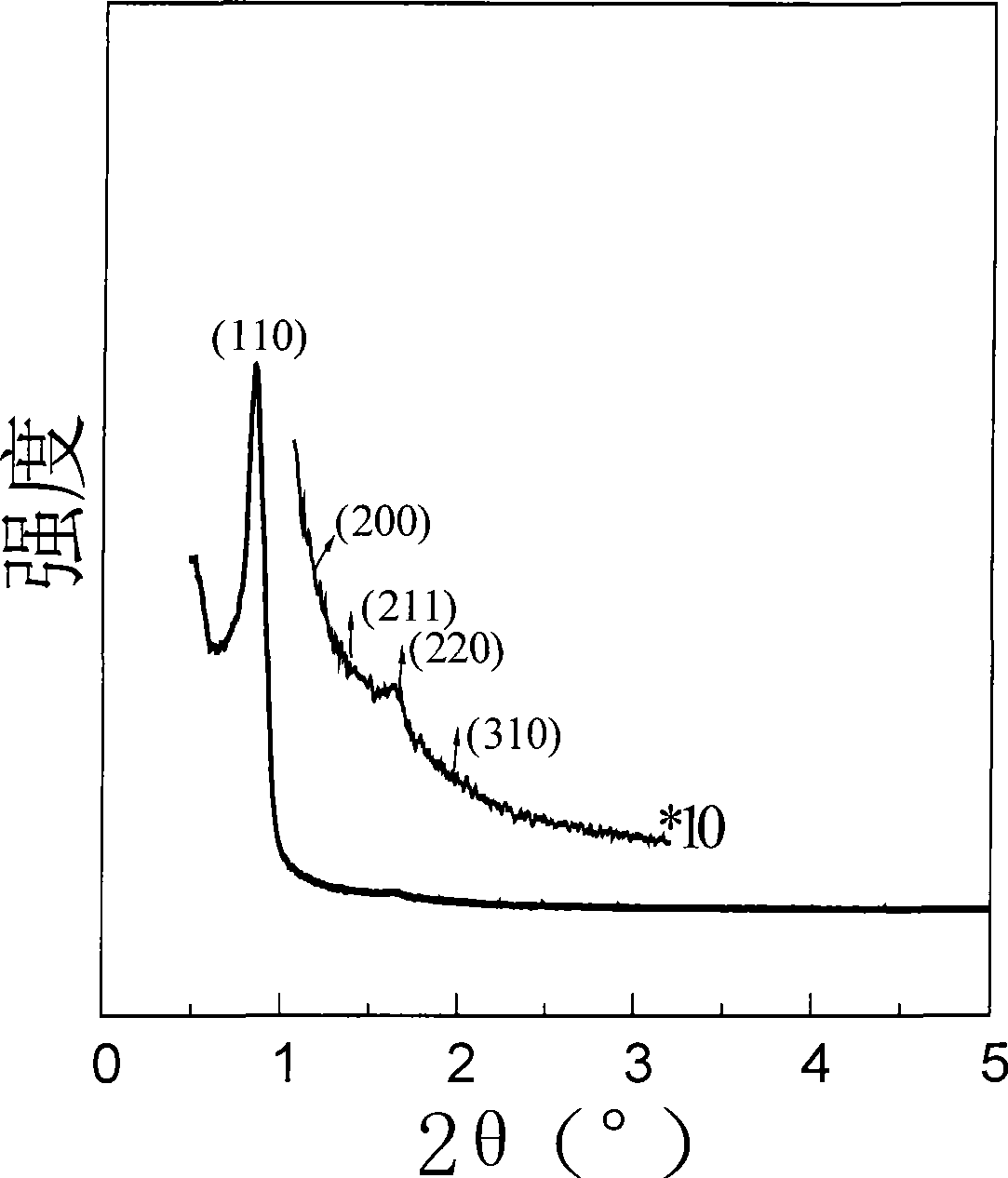

[0027] The operation method is the same as that in Example 1, except that the dosage of F108 is 1.5 g (the mass ratio of F108 to resorcinol is 1.5:2), and finally ordered mesoporous carbon is obtained. XRD analysis shows that the obtained material is a mesoporous carbon with a cubic hole structure.

Embodiment 3

[0029] The operation method is the same as that in Example 1, except that the amount of F108 used is 3.5 g (the mass ratio of F108 to resorcinol is 3.5:2), and finally mesoporous carbon is obtained. XRD analysis shows that the obtained material is a mesoporous carbon with a cubic hole structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com