Purifying process for solution of wood vinegar

A process method, the technology of wood vinegar, applied in the field of design chemistry, can solve the problems of adverse effects of the use of downstream products, high energy consumption, and the inability to guarantee the original state of natural materials, etc., and achieve pollution control costs, small equipment volume, and easy implementation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be further described below in conjunction with embodiment:

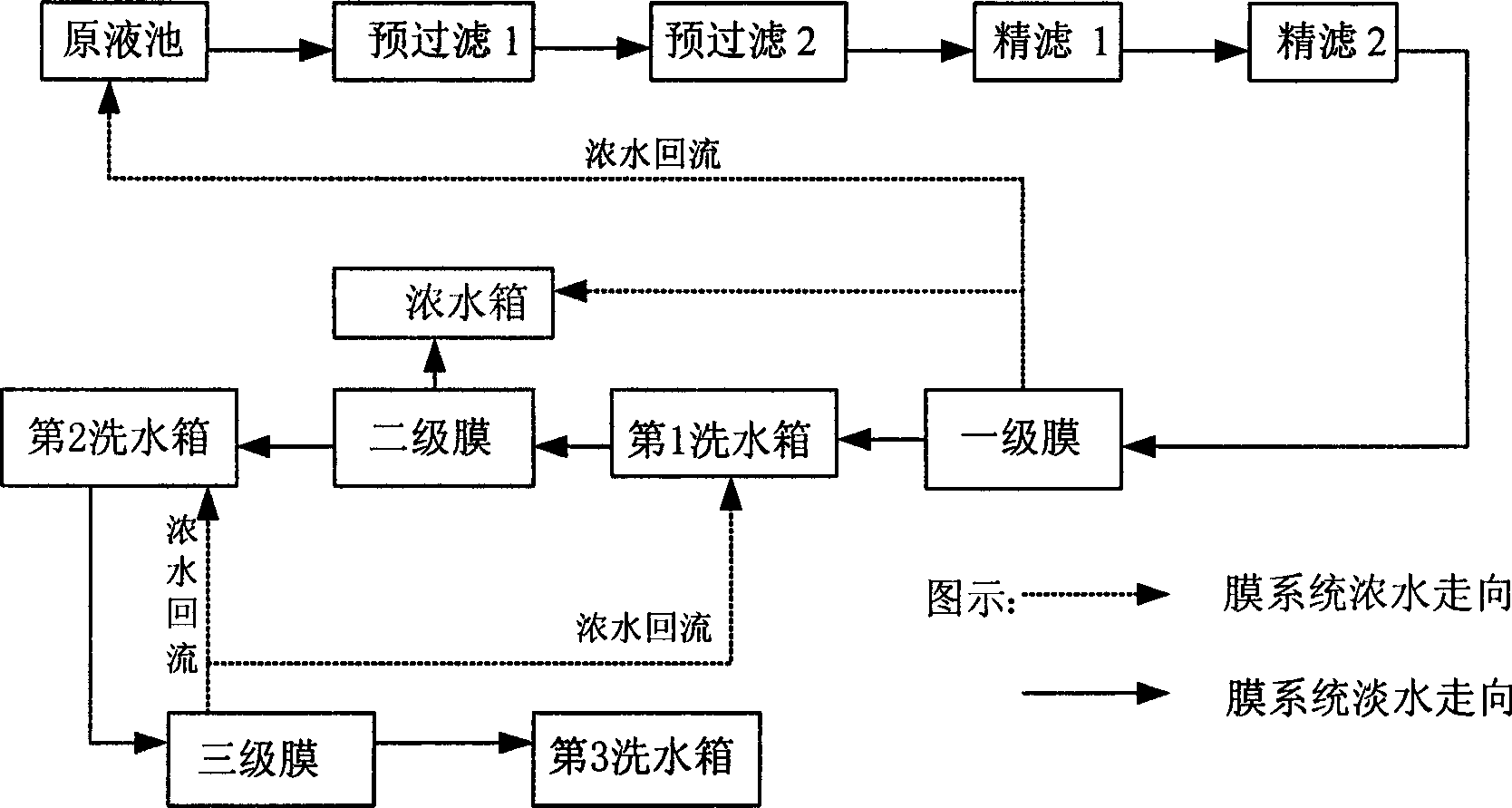

[0060] As shown in the figure, the process method of the present invention includes the following steps: a. Firstly, the raw solution that has been precipitated in the raw solution pool and cooled is sent into the two-stage pre-filtration and two-stage fine filtration system connected in series through the pipeline Filtration; b, the filtrate obtained in step a is sent to the multi-stage membrane separation system composed of three-stage membrane separation devices and three washing water tanks arranged in series at intervals through pipelines for separation; wherein, through a The concentrated water separated by the first-stage membrane separation device is sent to the raw liquid pool and the concentrated water tank through the pipeline; the concentrated water separated by the second-stage membrane separation device is sent to the concentrated water tank through the pipeline; The se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com