Process for preparing bacillus subtilis alkali proteinase with microorganism zymotechnics

A technology of Bacillus subtilis and microbial fermentation, which is applied in the production process of alkaline protease, can solve problems such as high cost, limited output, and limited enzyme application range, and achieve low production cost, short production cycle, and general equipment requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

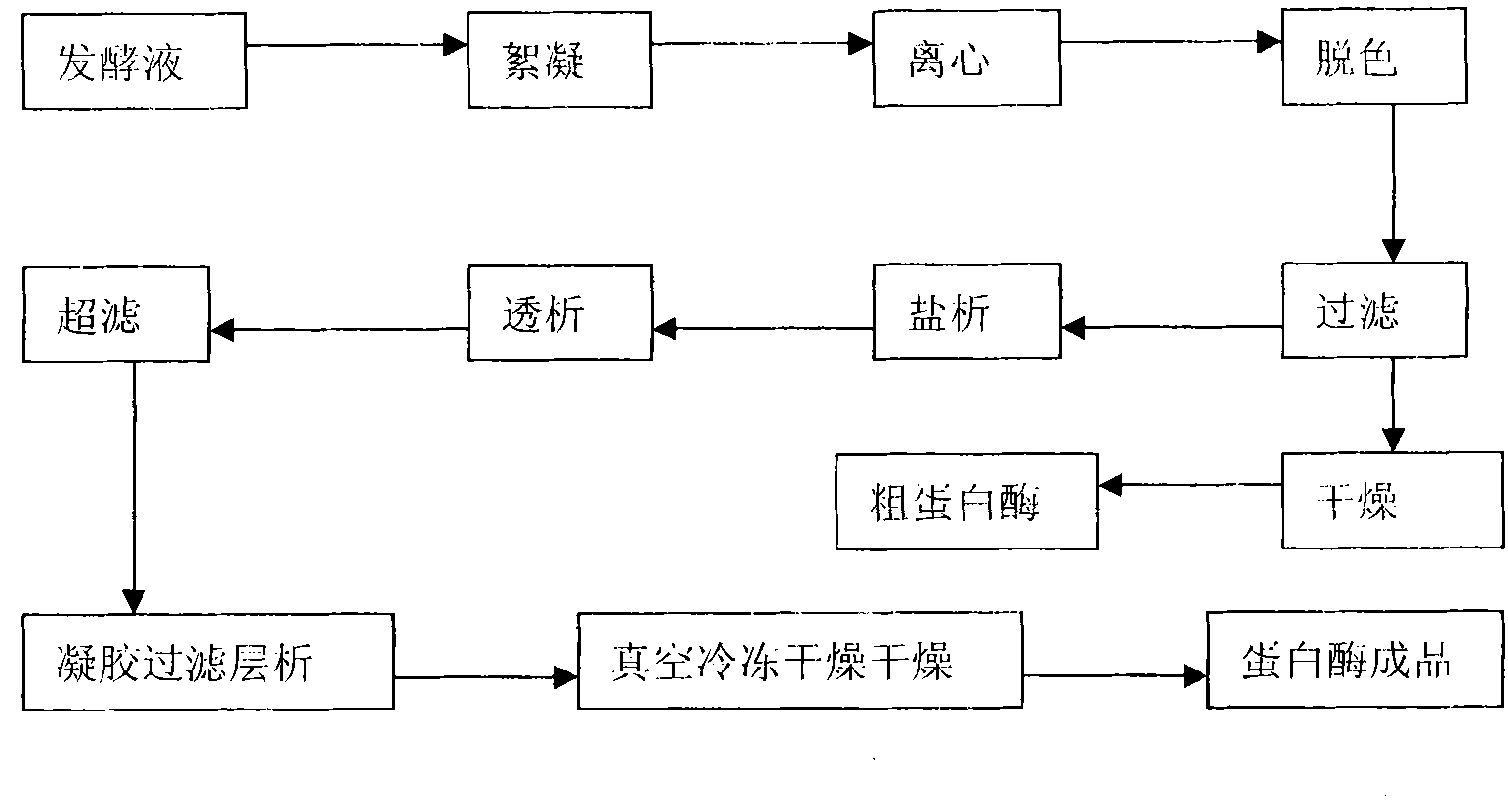

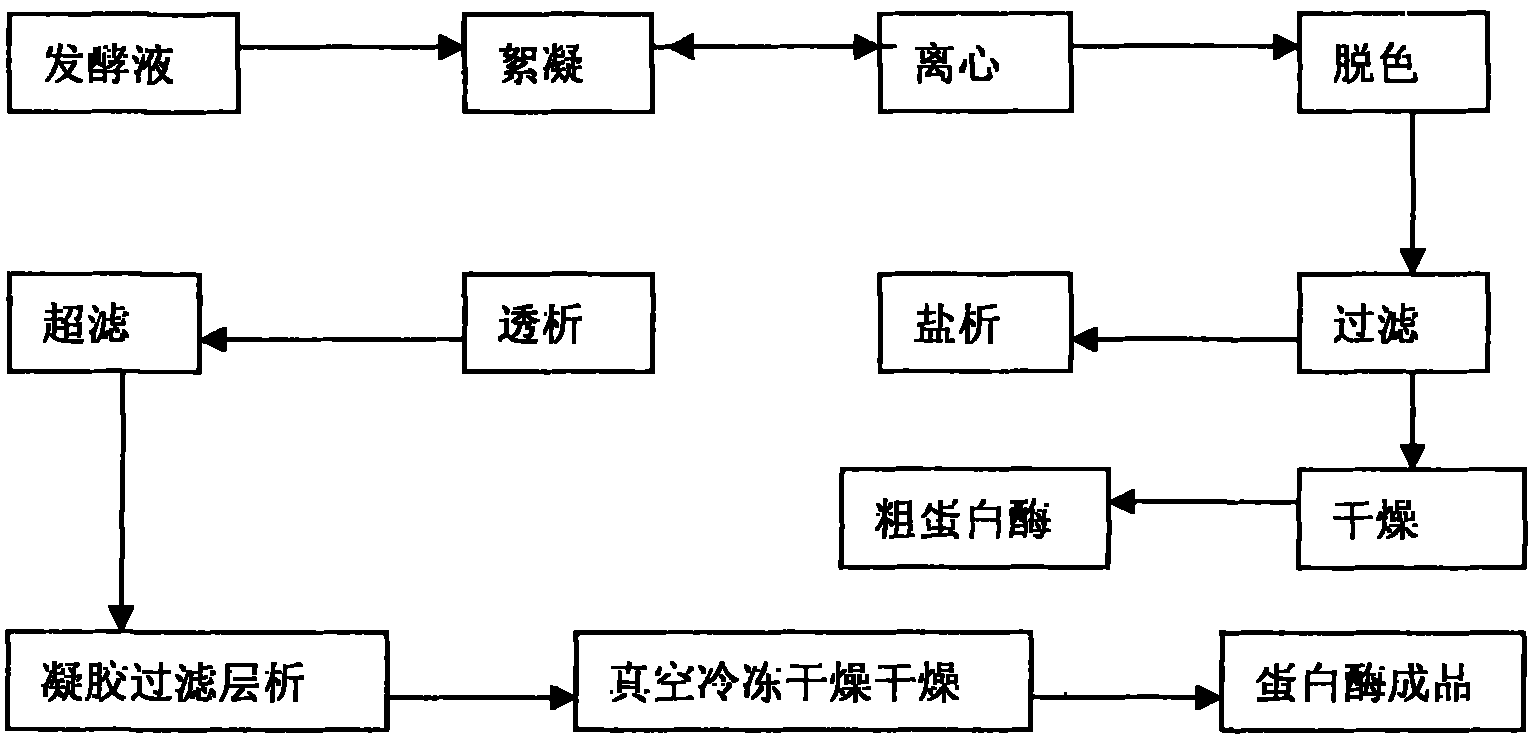

Method used

Image

Examples

Embodiment

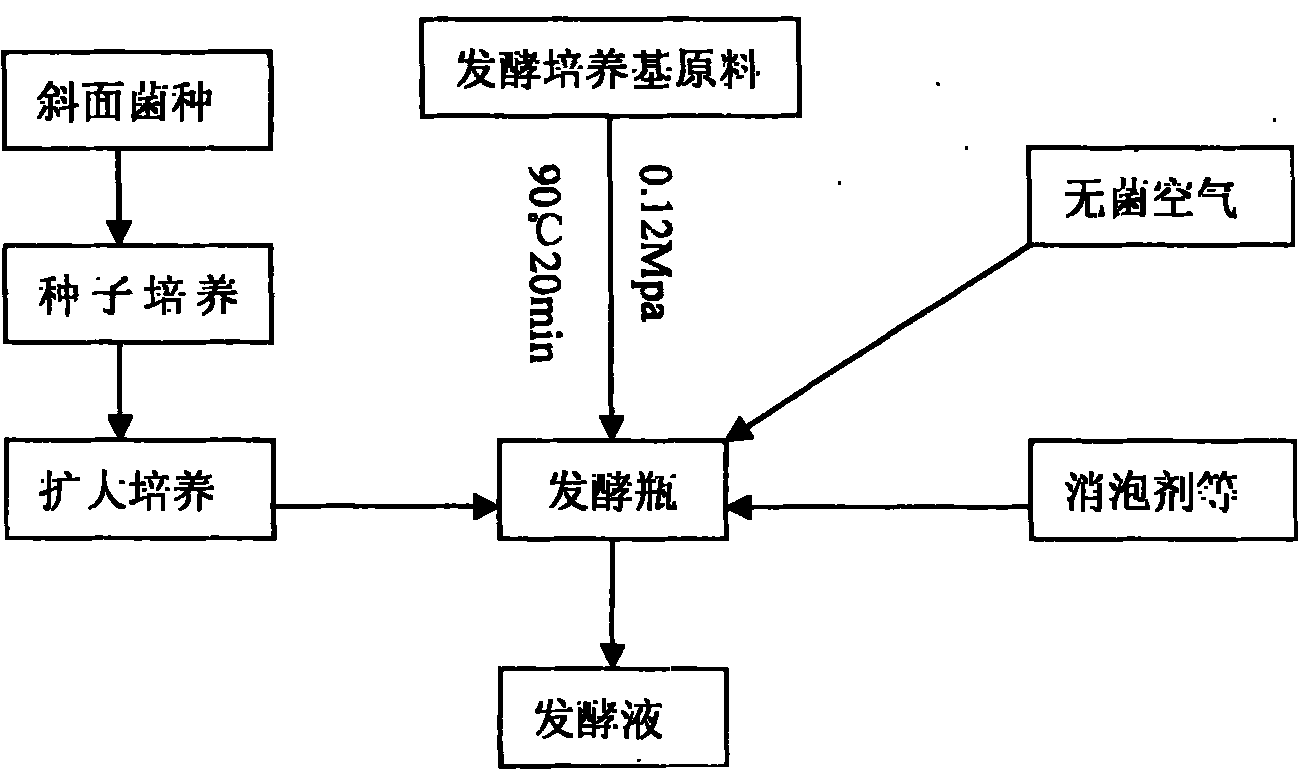

[0057] (1) Strain culture:

[0058] ①Seed medium:

[0059] LB liquid medium: peptone 10g, yeast extract 5g, NaCl 10g, water 1L, pH7.0, autoclaved at 121°C for 30min.

[0060] ② Expansion of training:

[0061] Use an inoculation loop to pick up a ring of BQ-An strain sludge stored on the slope, and inoculate it in a 250mL Erlenmeyer flask containing 100mL of seed medium. Cultivate for 36-38 hours under the condition of 38°C constant temperature shaker and 160r / min.

[0062] (2) Fermentation medium preparation:

[0063] a: The optimal formula (w / w) of the fermentation medium is: glucose 1.2% + sucrose 0.6% + starch 1.2%, bean cake powder 3%, yeast powder 0.3%, K 2 HPO 4 ·3H 2 O0.2%; the rest supplemented with distilled water. b: adjust the pH of the fermentation medium prepared according to the above formula to 7.8, pack it into a triangular flask, sterilize it at 0.105Mpa steam pressure for 30 minutes, cool it naturally to 45°C, and inoculate Bacillus subtilis strains un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com