Preparation an use of selenium-coated copper chloride hydroxide

A copper chloride, basic technology, applied in the field of compound preparation, can solve the problems of low water solubility, difficult mixing and uniform dispersion, high production cost, etc., and achieve the effects of stable chemical properties, good biological palatability, and mild reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following examples are further explanations and illustrations of the present invention, and do not constitute any limitation to the present invention.

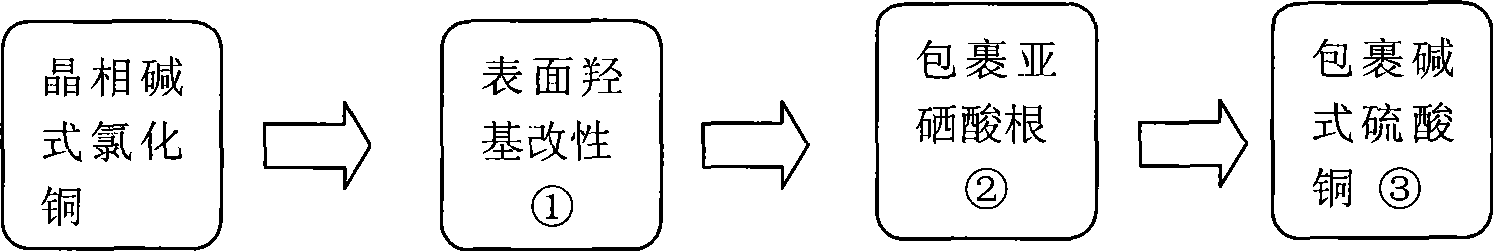

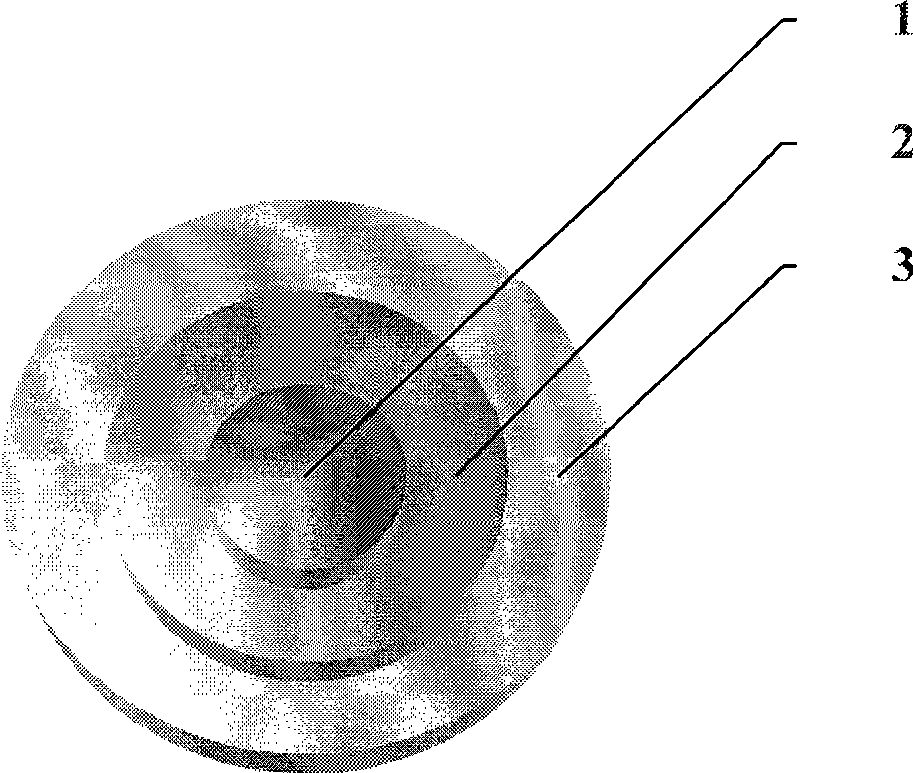

[0034]1. Preparation of selenium-coated basic copper chloride

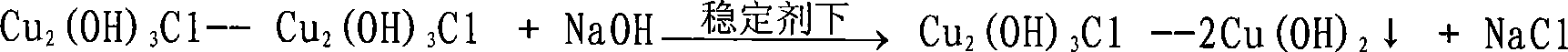

[0035] in 2M 3 Add 1000 kg of botallackite in the enamel reaction tank, inject 1500 liters of tap water, and add 1 kg of glycerin. Then start the stirring paddle of the reaction tank, slowly add 350 kilograms of sodium hydroxide solution with a concentration of 20%, react for 1 hour at a reaction temperature of 30 to 60°C until the pH value is 9, and then discharge the material into a vacuum filter for suction filtration, and then use tap water Washing and suction filtration to dryness to obtain hydroxyl-modified crystal phase basic copper chloride. Add the hydroxyl-modified crystal phase basic copper chloride to 2M 3 In the enamel reaction tank, inject 1500 liters of tap water, under the conditions of stirring and reaction temperature 30-60 ℃, add 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com