Electrical insulation oil and preparation thereof

A technology of electrical insulating oil and manufacturing method, which is applied in the petroleum industry, base material, thickener and other directions to achieve the effects of preventing insulation damage, excellent practical performance and excellent electrical performance

Active Publication Date: 2009-02-25

JAPAN ENERGY CORP

View PDF4 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0007] The purpose of the present invention is to overcome the defects of existing electrical insulating oil and its manufacturing method, and provide a new electrical insulating oil and its manufacturing method. The technical problem to be solved is to make it even without using The deteriorating pour point depressant has a low pour point and excellent hydrogen absorption, which can prevent insulation damage caused by the freezing and floating of moisture mixed in the transformer. Because of the high flash point, the risk of fire is low, and further Because it contains almost no sulfur, it is completely non-corrosive to copper, has excellent electrical properties, and has excellent practical performance

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

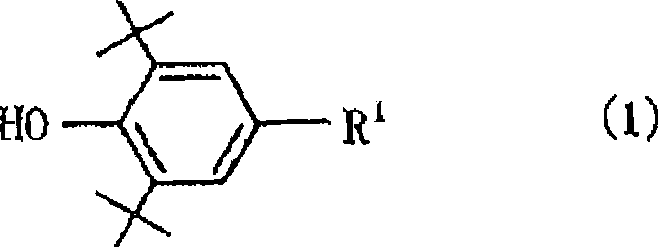

[0064] 0.3% by mass of 2,6- Di-tert-butyl-4-methylphenol (DBPC) was used as an antioxidant to prepare electrical insulating oil A.

Embodiment 2

[0066] 0.3% by mass of 2,6- Di-tert-butyl-4-methylphenol (DBPC) was used as an antioxidant to prepare electrical insulating oil B.

Embodiment 3

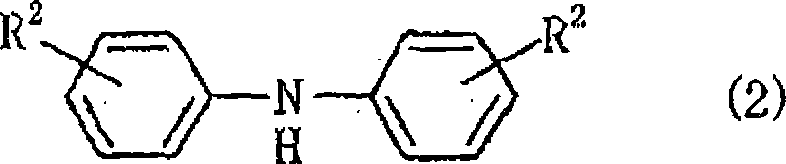

[0068] To the same mixed base oil as that used in Example 1, 0.3% by mass of 4,4'-dinonyldiphenylamine (ADPA) was added as an antioxidant to prepare electrical insulating oil C.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

Login to View More

Abstract

This invention is related to an electric insulating oil and preparation method, which have low pour point and excellent hydrogen absorbency even if not using the pour inhibitor that can worsen the electric performance, and prevent the insulative damage caused by the upward floating when the moisture content mixed inside the transformer is frozen, such that the flash point is higher and the fatalness of occurring fire is lower. And this invention has no causticity to the copper because of without having the sulfur and has excellent electric performance, so that the practicality is excellent. The electric insulating oil is characterized that: the pour point is not greater than 45 below zero; the kenematic viscosity (40 degrees centigrade) is 6mm (2) to 10 mm (2); the flash point (PM) is not smaller than 135 degrees centigrade; the density (20 degrees centigrade) is not greater than 0.895kg / L; the aniline point is 63 to 90 degrees centigrade; the sulfur content is less than 3 weight ppm; the nitrogen content is not greater than 3 weight ppm; the basic nitrogen content is not greater than 1 weight ppm; the aromatic series content is not smaller than 5 weight%; and the antioxidant of 0.05 weight% to 0.5 weight% is contained.

Description

technical field [0001] The present invention relates to a kind of electric insulation oil and its manufacturing method, especially relates to a low pour point, suitable for cold areas, but high flash point, and because it contains almost no sulfur, so it is completely non-corrosive to copper, An electrical insulating oil having excellent oxidation stability and therefore excellent practical performance, and a method for producing the same. Background technique [0002] Electrical insulating oil is filled and used in high-voltage electrical equipment such as transformers, high-voltage cables, high-voltage circuit breakers, and capacitors. In these electrical appliances, transformers, etc. are designed in such a way that the electrical insulating oil is circulated and cooled by forced or natural convection in order to dissipate the heat generated by the coil, etc. At this time, the cooling of the electrical insulating oil with low kinematic viscosity Excellent performance. H...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C10M169/04C10M105/04C10M121/02C10M129/10C10M133/44C10N30/10C10N40/16

CPCC10M171/00C10M171/02C10N2030/10C10N2040/16

Inventor 森岛欣之

Owner JAPAN ENERGY CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com