Busbar connection device

A busbar connection and busbar connector technology, applied in the direction of connection, conductive connection, electrical component connection, etc., can solve the problems of easy loosening of insulating sleeves, large space occupation, exposed cable heads, etc., and achieves low technical level requirements and device structure. Small size, good insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

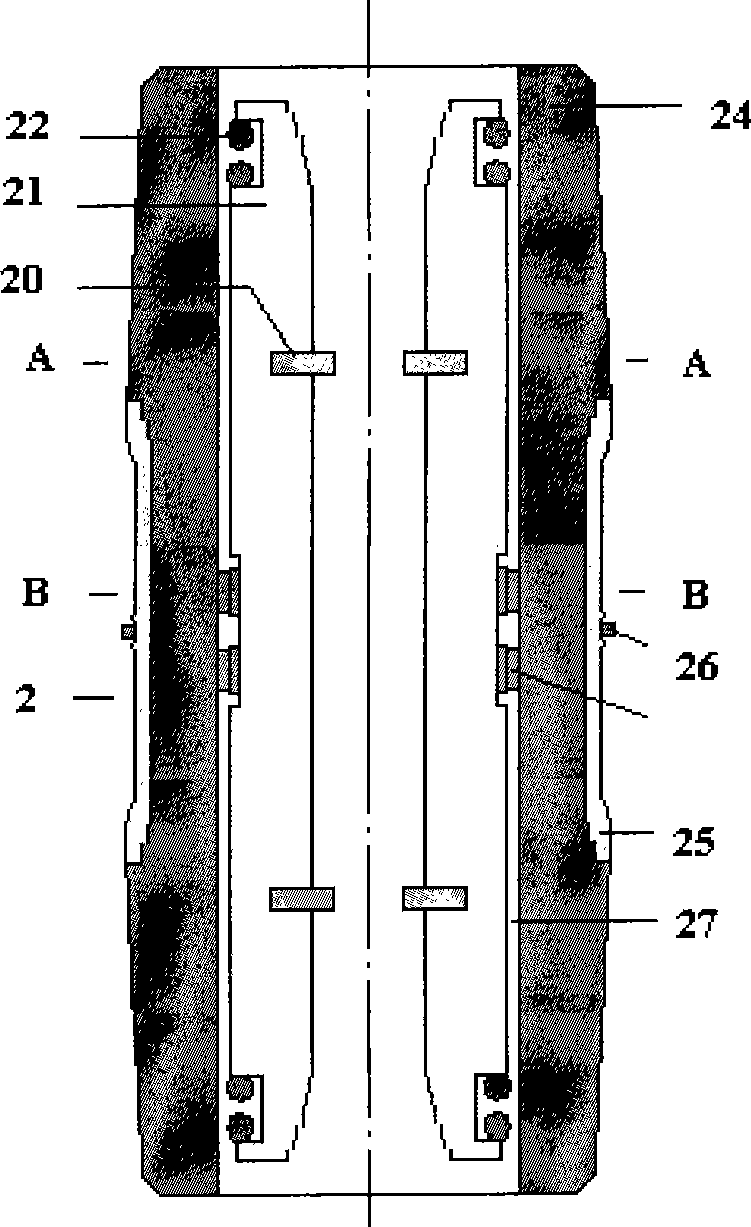

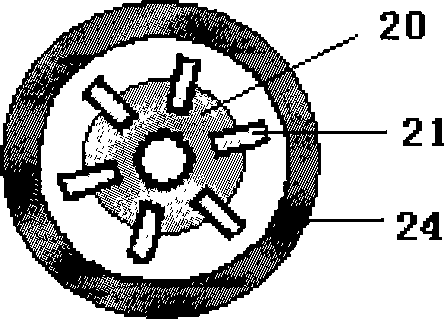

[0024] A bus connection device, characterized in that it is a supporting product composed of two bus insulators 1 and a bus connector 2, the structures of the two bus insulators 1 are exactly the same, and the bus insulator 1 includes an insulating cover 10 and an electrical contact 11, The material constituting the insulating cover 10 is epoxy resin, the insulating cover 10 is cup-shaped, q mounting holes 103 are evenly distributed on the cover opening 101 of the insulating cover 1, q is a natural number from 3 to 8, and each mounting hole 103 is sealed Intrinsic insert nut 104, the constituent material of electric contact 11 is copper, the bottom, middle part and head of electric contact 11 are respectively cylindrical, cylindrical and truncated cone, electric contact 11 is sealed in insulating cover 10 and insulated The central part of the cover bottom 102 of the cover 10, the bottom of the electric contact 11 runs through the cover bottom 102 of the insulating cover 10, the...

Embodiment 2

[0026] Except for the following differences, the remaining parts are identical to Example 1.

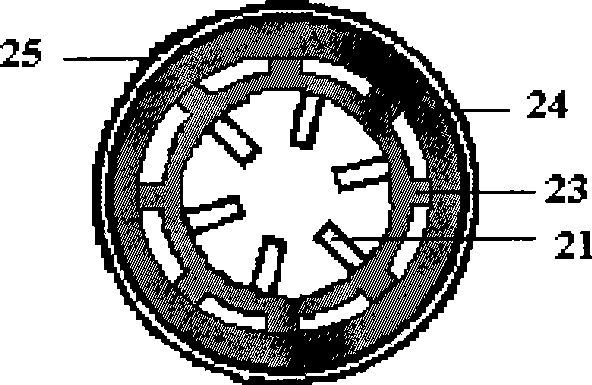

[0027]The busbar connector 2 also includes a shielding sheath 25, a grounding spring coil 26 and a grounding wire. The middle ring line of the insulating sheath 24 has a circular groove in cross section. The material constituting the shielding sheath 25 is silicon rubber. The shielding sheath The sleeve 25 is in the shape of a round tube, the grounding spring ring 26 is a thin spring connected end to end, the grounding wire is an insulated wire, the shielding sheath 25 is hooped in the middle of the outer wall of the insulating sheath 24, and the grounding spring coil 26 is hooped in the shielding sheath 25 in the depression, the wire at one end of the grounding wire is twisted with the grounding spring coil 26, and during use, the other end of the grounding wire is connected to the grounding wire terminal of a current-carrying busbar place equipment.

Embodiment 3

[0029] Except for the following differences, the remaining parts are identical to Example 1. m=12, n=4, p=8, q=6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com