Intelligent heat tray temperature controller and temperature control method thereof

A temperature control method and temperature controller technology, applied in the direction of temperature control, non-electric variable control, control/regulation system, etc., can solve the problems of insufficient response speed and low control accuracy, and achieve rapid response, accurate temperature control, The effect of constant temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

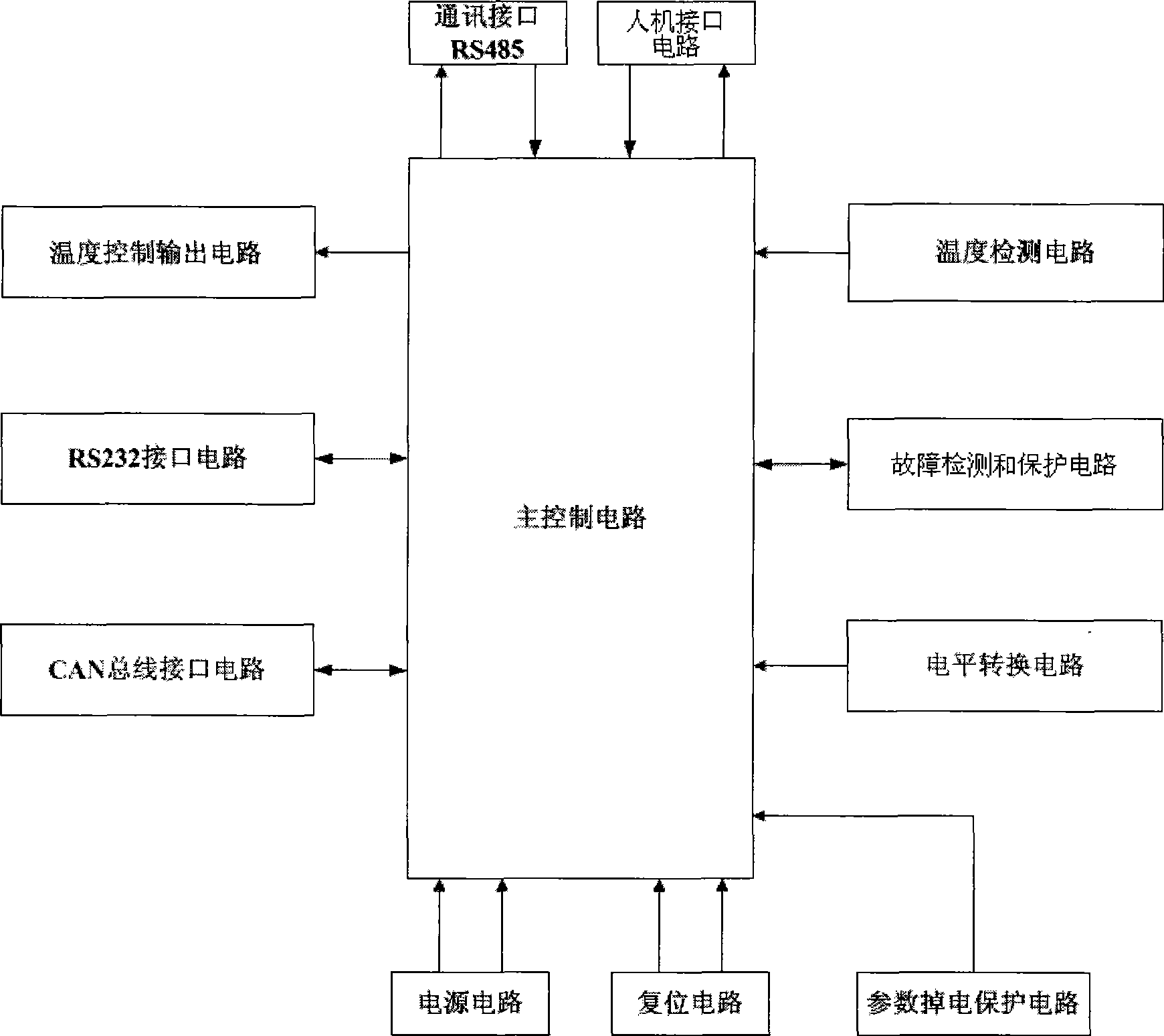

[0041] Such as figure 1 As shown, in order to solve the problem of hot plate temperature control in the semiconductor production process, the device of the present invention is a single-chip microcomputer (this embodiment adopts C8051F040) as the control core of the main control circuit, combined with a parameter power-down protection circuit (this embodiment A closed-loop control system is formed by adopting a memory storage chip EEPROM), a temperature detection circuit (the present embodiment adopts a tiny signal detection chip), a communication interface, and a temperature control output circuit composed of a power amplifier and a solid-state relay.

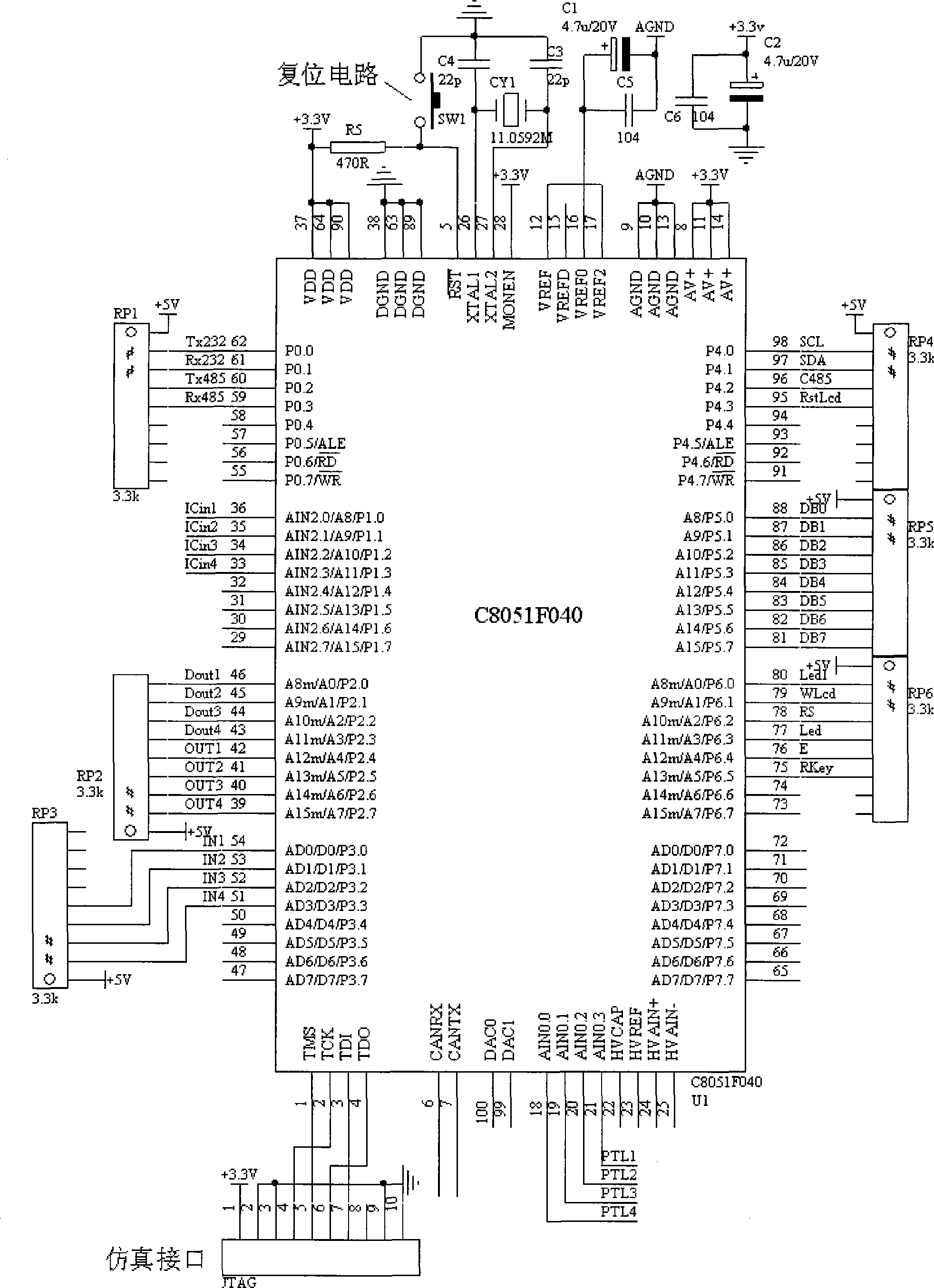

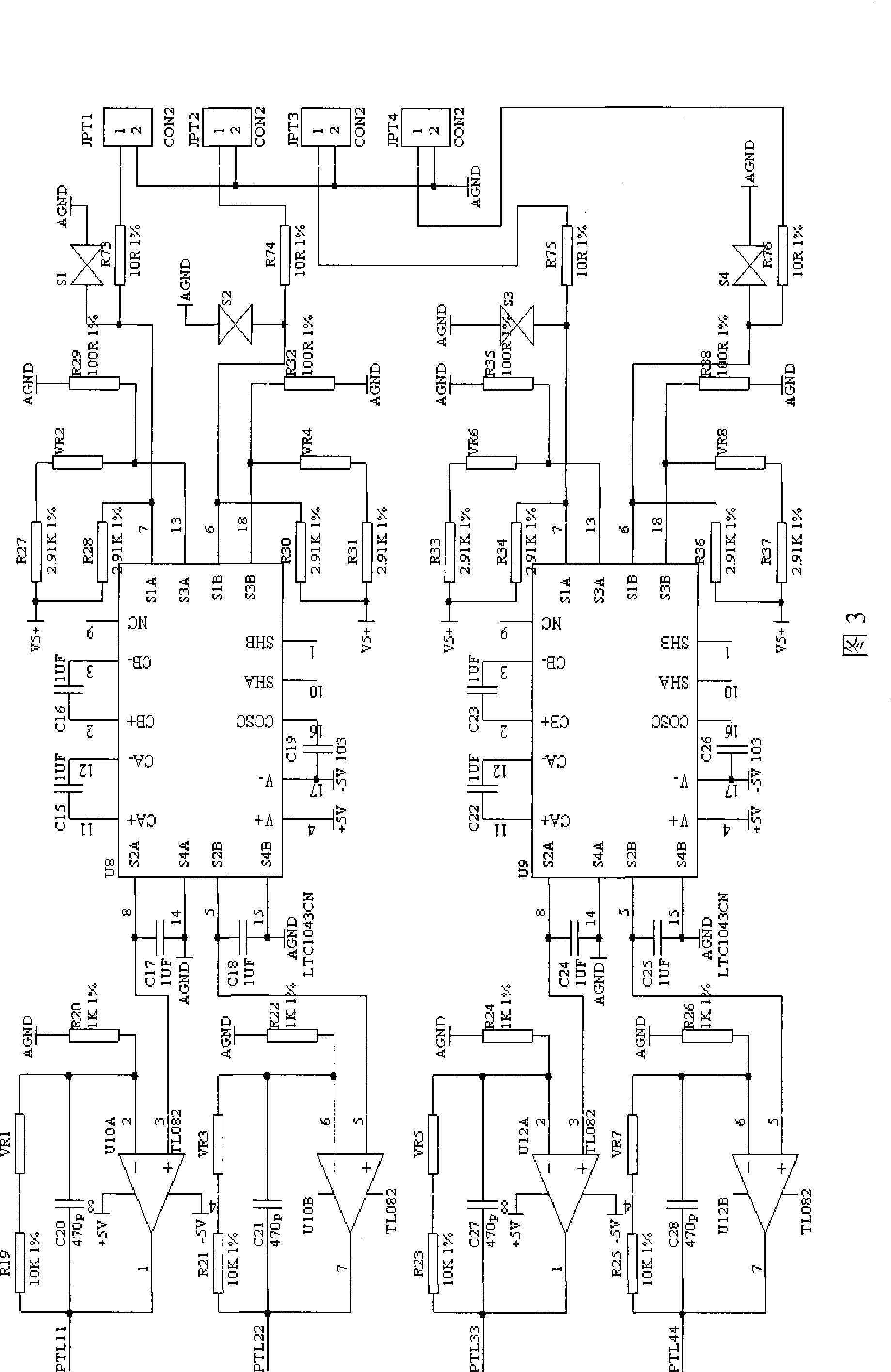

[0042] Such as figure 2 , 3 and shown in Figure 4, the present embodiment adopts 4-way temperature detection and control, and platinum resistors are respectively installed in the 4 hot plate bodies as the hot plate temperature sensors, which are connected to the single-chip microcomputer through the temperature detection circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com