Rotary motor and method for manufacturing electric brush thereof

A technology of rotating motor and direction of rotation, applied in the manufacture of brushes, rotary current collectors, and contact parts, etc., can solve the problems of long time, shortened operation processing time, volume reduction, etc., and achieves long life and shortened operation processing time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiment 1

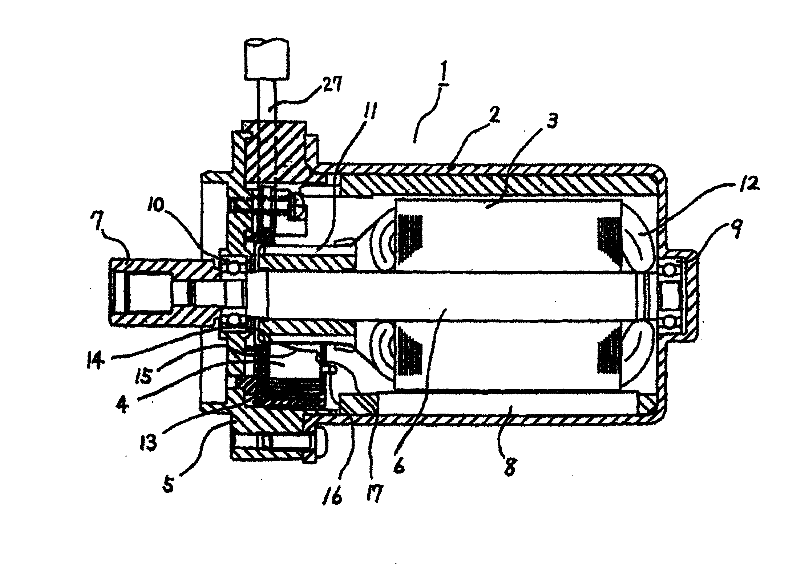

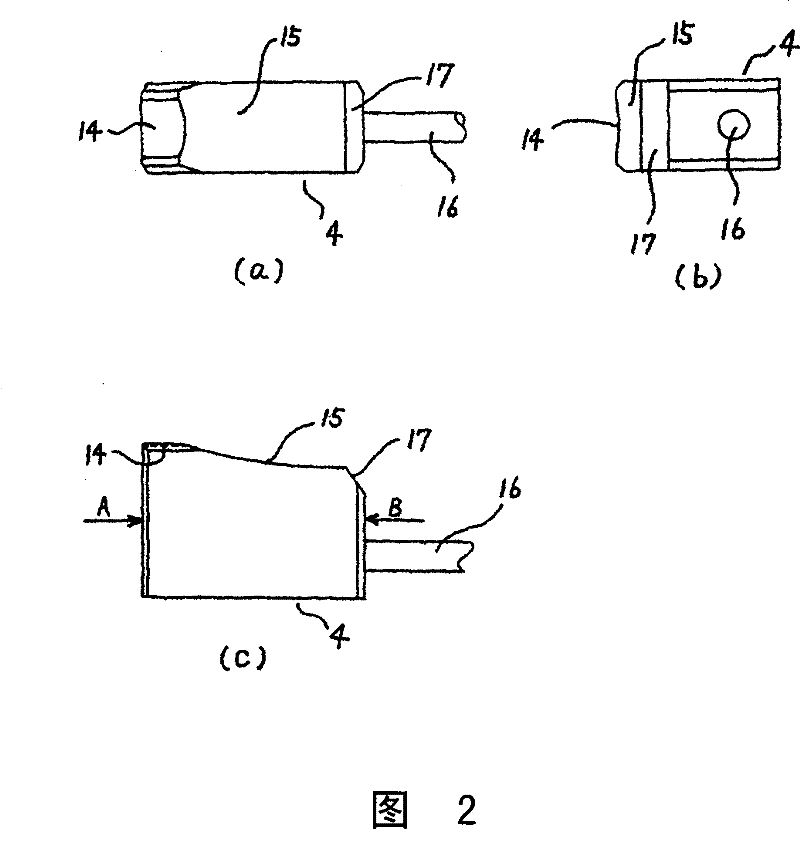

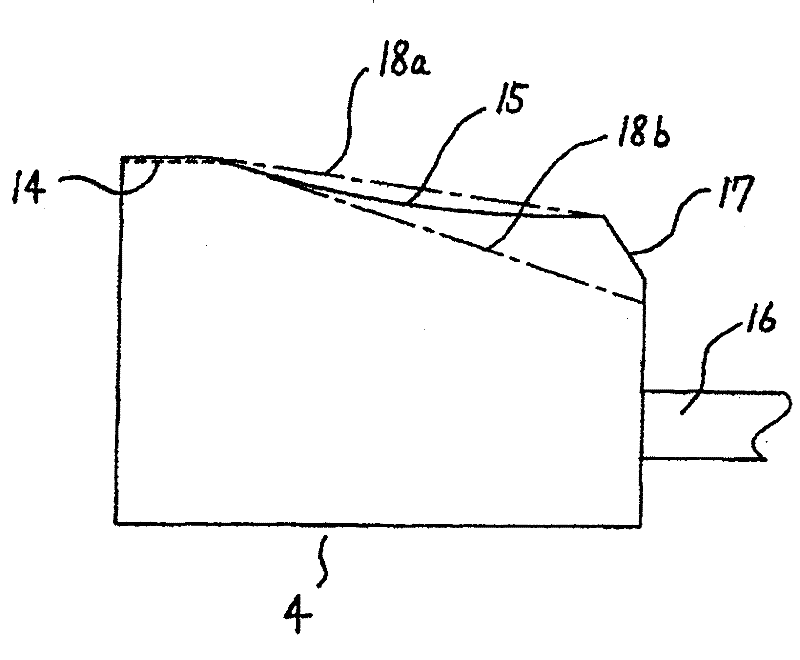

[0022] according to Figure 1 ~ Figure 4 , Embodiment 1 will be described. In addition, in each figure, the same reference numerals are assigned to the same or corresponding parts for description. figure 1 is a sectional view of an electric motor for electric power steering, figure 2 for figure 1 An explanatory diagram of the brush shape of the motor, image 3 for will figure 2 An explanatory diagram comparing the removed part of the brush with the inclined surface of a conventional brush. Figure 4 for figure 2 Explanatory diagram of the formation of the removal part of the brush.

[0023] exist figure 1 Among them, an electric motor 1 for an electric power steering device forming a rotating electric machine has: a bottomed cylindrical yoke 2 forming a stator; an armature 3 forming a rotor disposed inside the yoke 2; Brush 4; end cap 5 fitted into the opening of yoke 2 and fixed to yoke 2; and hub 7 fixed to one end of rotating shaft 6 of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com