Preparation method of large-area nano-microparticles monolayer film

A nano-particle and single-layer film technology, which is applied to devices and coatings that apply liquid to the surface, can solve the problems of uneven particle size distribution of nano-films, difficult to control large-area films, and lack of application value. , to achieve the effect of simple operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

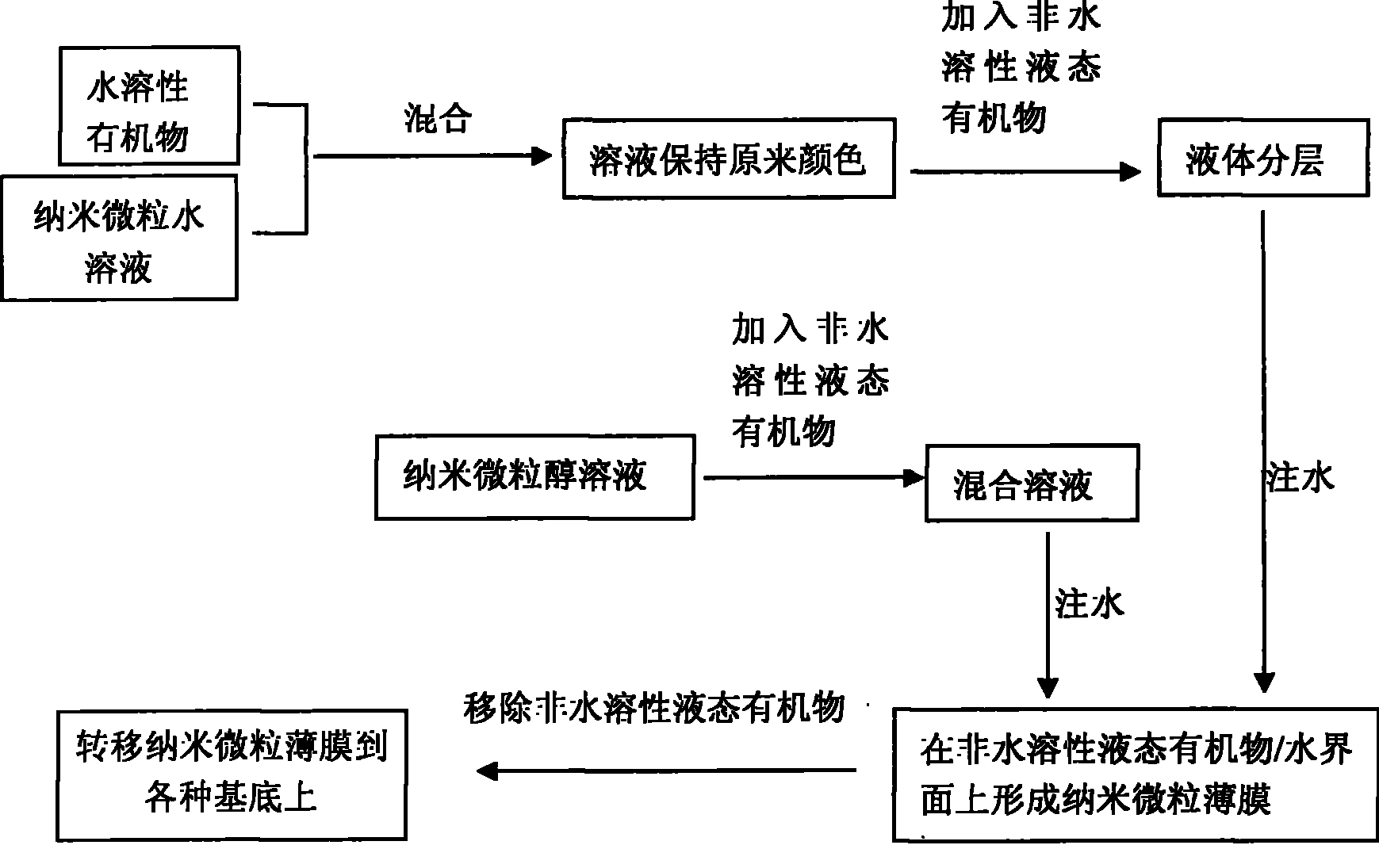

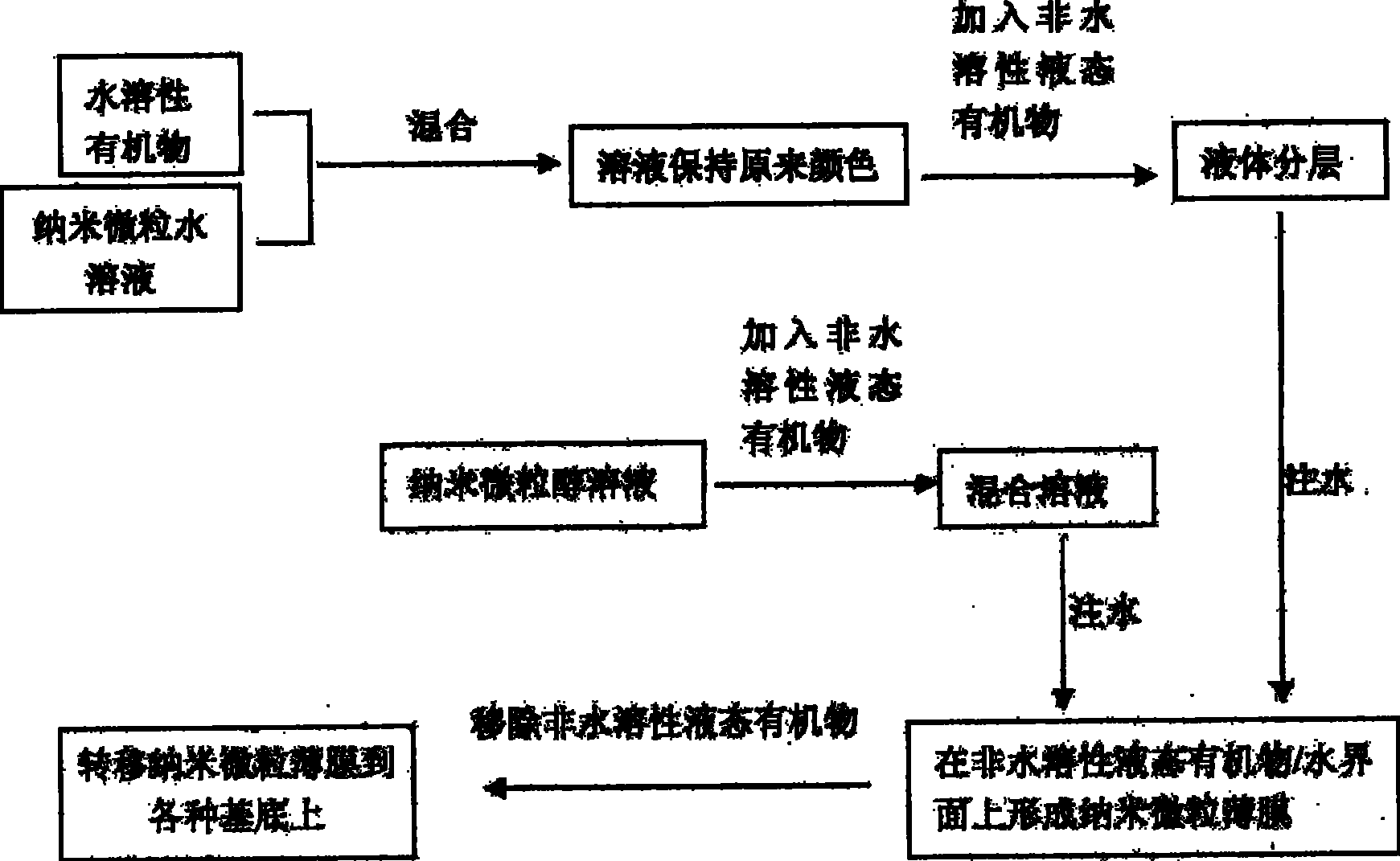

Method used

Image

Examples

Embodiment 1

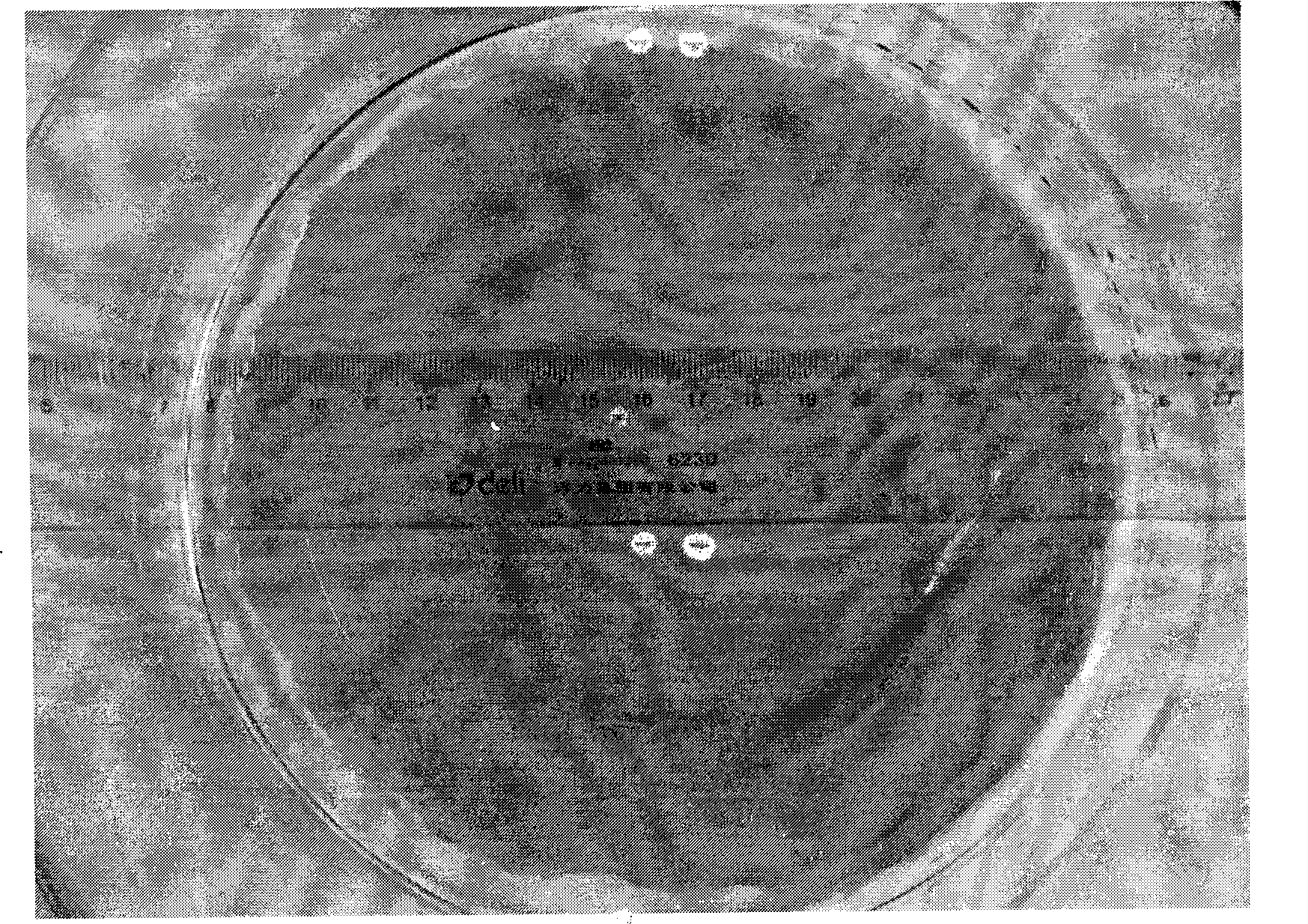

[0043] Add 3mL propanol to 5mL gold nanoparticle aqueous solution with a concentration of 0.91g / L, and then add 2mL benzene to form a benzene / water interface. After 2mL of water is injected, a gold nanoparticle film is formed on the benzene / water interface. The film was transferred to the substrate by pulling up and was observed under transmission electron microscopy (see Figure 3).

Embodiment 2

[0045] Add 2mL methyl ethyl ketone to 5mL gold nanoparticle aqueous solution with a concentration of 0.074g / L, and then add 2mL toluene to form a toluene / water interface. After 2mL of water is injected, a gold nanoparticle film is formed on the toluene / water interface, and then The film was transferred to the substrate by pulling up and was observed under transmission electron microscopy (see Figure 4).

Embodiment 3

[0047] Add 4mL butyric acid to 5mL gold nanoparticle aqueous solution with a concentration of 0.00043g / L, and then add 2mL cyclohexane to form a cyclohexane / water interface. After 2mL of water is injected, the gold nanoparticle film is in the cyclohexane / water The film is formed on the interface, and then the film is transferred to the substrate by the pulling method for transmission electron microscopic observation (see Figure 5).

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com