Production method for drying anhydrous sodium sulfate using fluidized bed

A technology of fluidized bed drying and anhydrous sodium sulfate, which is applied in the direction of alkali metal sulfite/sulfate dehydration, etc., can solve the problems of high tail gas discharge temperature, difficult packaging process, high product temperature, etc., and achieve energy consumption reduction, post-processing The effect of smooth packaging and low product temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

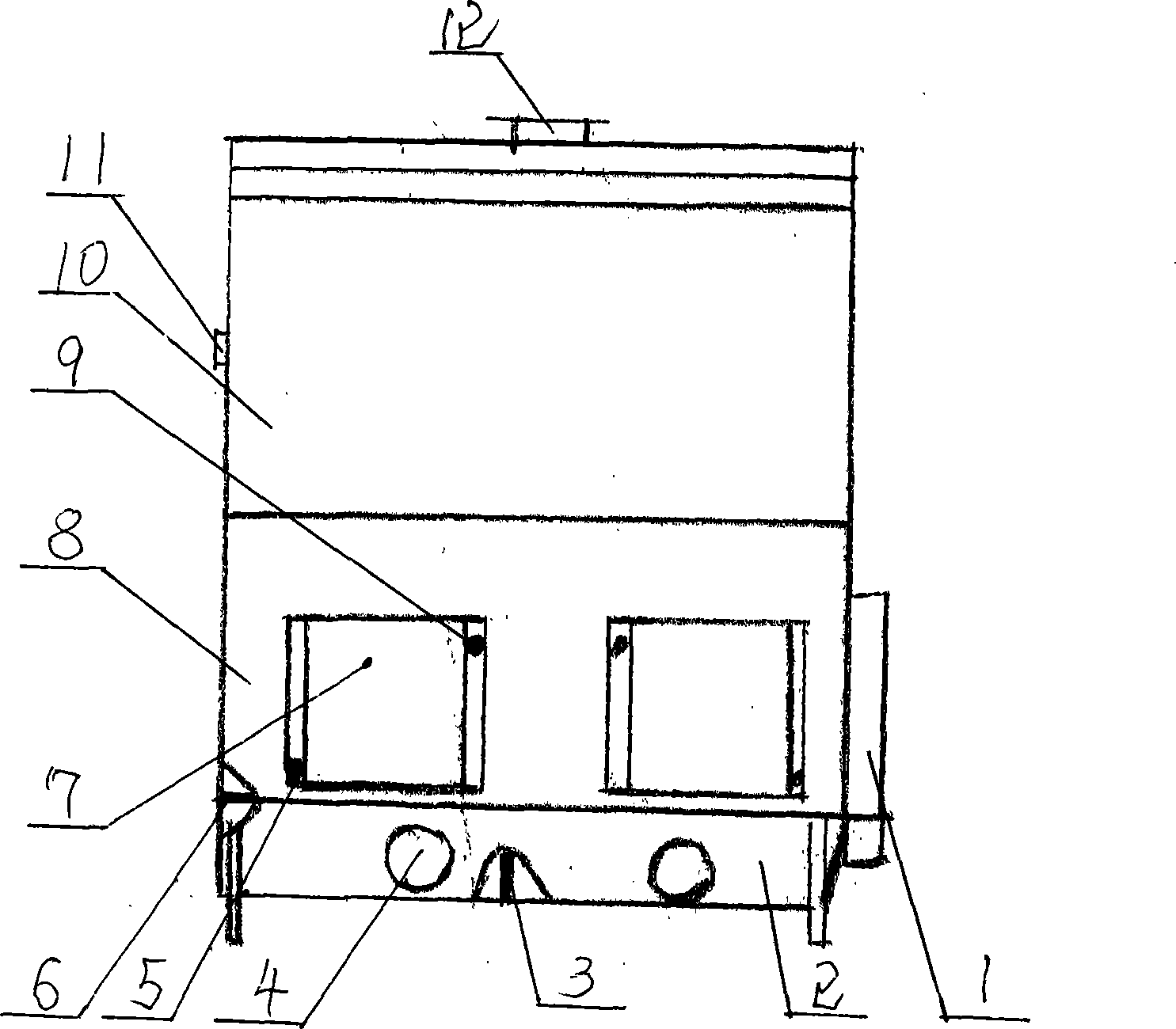

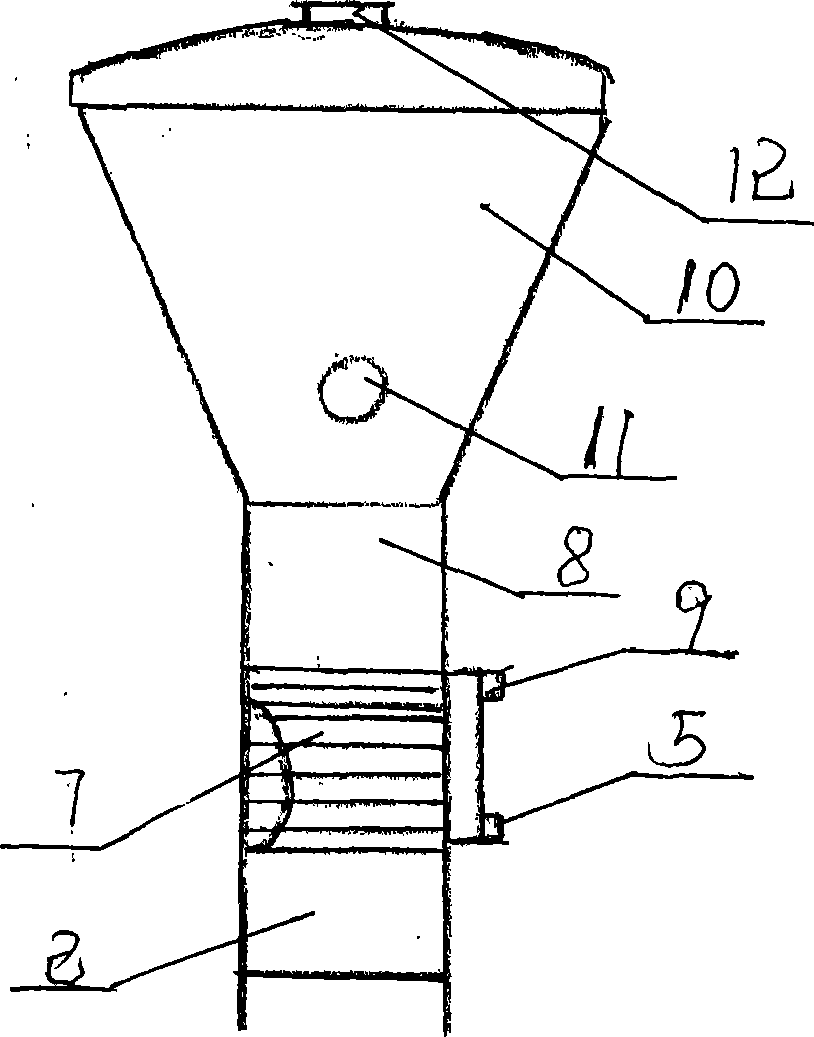

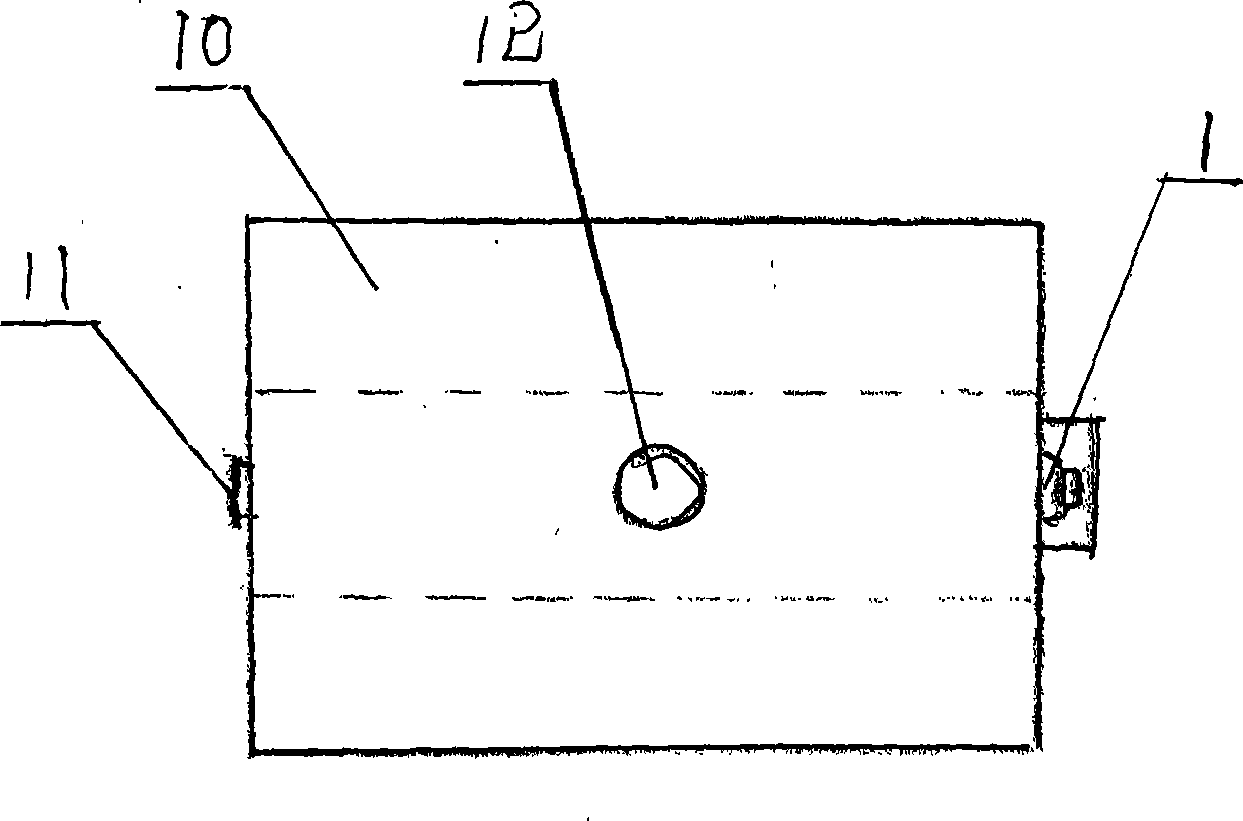

[0016] Embodiment 1, as attached Figure 4 Shown, utilize fluidized bed to dry the production method of anhydrous sodium sulfate, the sodium sulfate wet material containing moisture 1.6% that separates out from separating machine, enter fluidized bed drier through feeder and dry, and dry hot air is controlled at 35 ℃ ~ 185 ℃, then pack the dry material collected from the discharge port and the cyclone separator to obtain the anhydrous sodium sulfate product.

[0017] The product test result is: Na 2 SO 4 : 99.6%, moisture: 0.02%.

Embodiment 2

[0018] Example 2: The sodium sulfate wet material with a moisture content of 2.4% separated from the separation machine enters the fluidized bed dryer through the feeder for drying, and the drying hot air is controlled at 35 ° C to 185 ° C, and then the material is discharged from the discharge port Pack the dry material collected with the cyclone separator to obtain the anhydrous sodium sulfate product.

[0019] The product test result is: Na 2 SO 4 : 99.4%, moisture: 0.04%.

Embodiment 3

[0020] Example 3: The sodium sulfate wet material with a moisture content of 3.8% separated from the separation machine enters the fluidized bed dryer through a feeder for drying, and the drying hot air is controlled at 35°C to 185°C, and then the material is discharged from the discharge port Pack the dry material collected with the cyclone separator to obtain the anhydrous sodium sulfate product.

[0021] The product test result is: Na 2 SO 4 : 99.2%, moisture: 0.05%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com