Tissue engineering reactor with torsion and tension-compression functions

A technology of tissue engineering and reactor, which is applied in the direction of specific-purpose bioreactor/fermenter, bioreactor/fermenter combination, tissue cell/virus culture device, etc. The effect of great potential social and economic benefits, great promotion and application prospects, and good mass transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

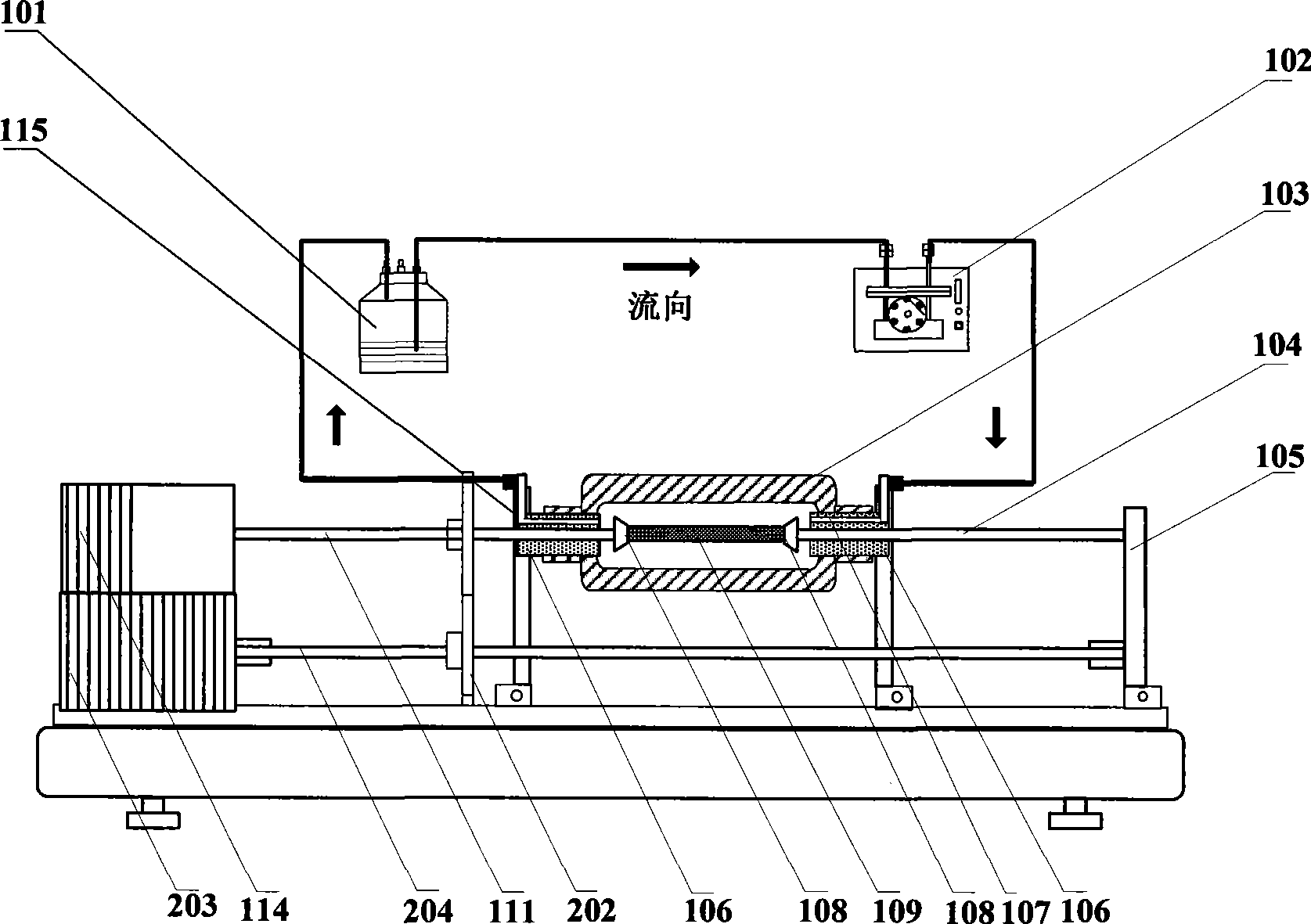

[0067] Example 1 Twisted tension and pressure perfusion

[0068] 1. According to figure 1 The tissue culture cavity perfusion circuit is connected as shown, wherein the liquid driving device is a peristaltic pump (Cole-Parmer Company, Masterflex series);

[0069] 2. Sterilize the reactor, the disinfection conditions are: 130°C, 3 atmospheres, 1 hour;

[0070] 3. Install the bone tissue culture to be cultured on the jig in the tissue culture chamber in a sterile state, wherein the bone tissue culture has a diameter of 4 mm and a length of 5 cm, and the scaffold material is hydroxyapatite;

[0071] 4. According to figure 1 The tissue culture torsion device is connected as shown, wherein the tissue culture torsion motor is a Haydn 57000 series stepper motor;

[0072] 5. According to figure 1 The connecting bone tissue pulling and pressing device is shown, wherein the bone tissue pulling and pressing motor is a Haydn 57000 series linear stepper motor;

[0073] 6. Prepare the ...

Embodiment 2

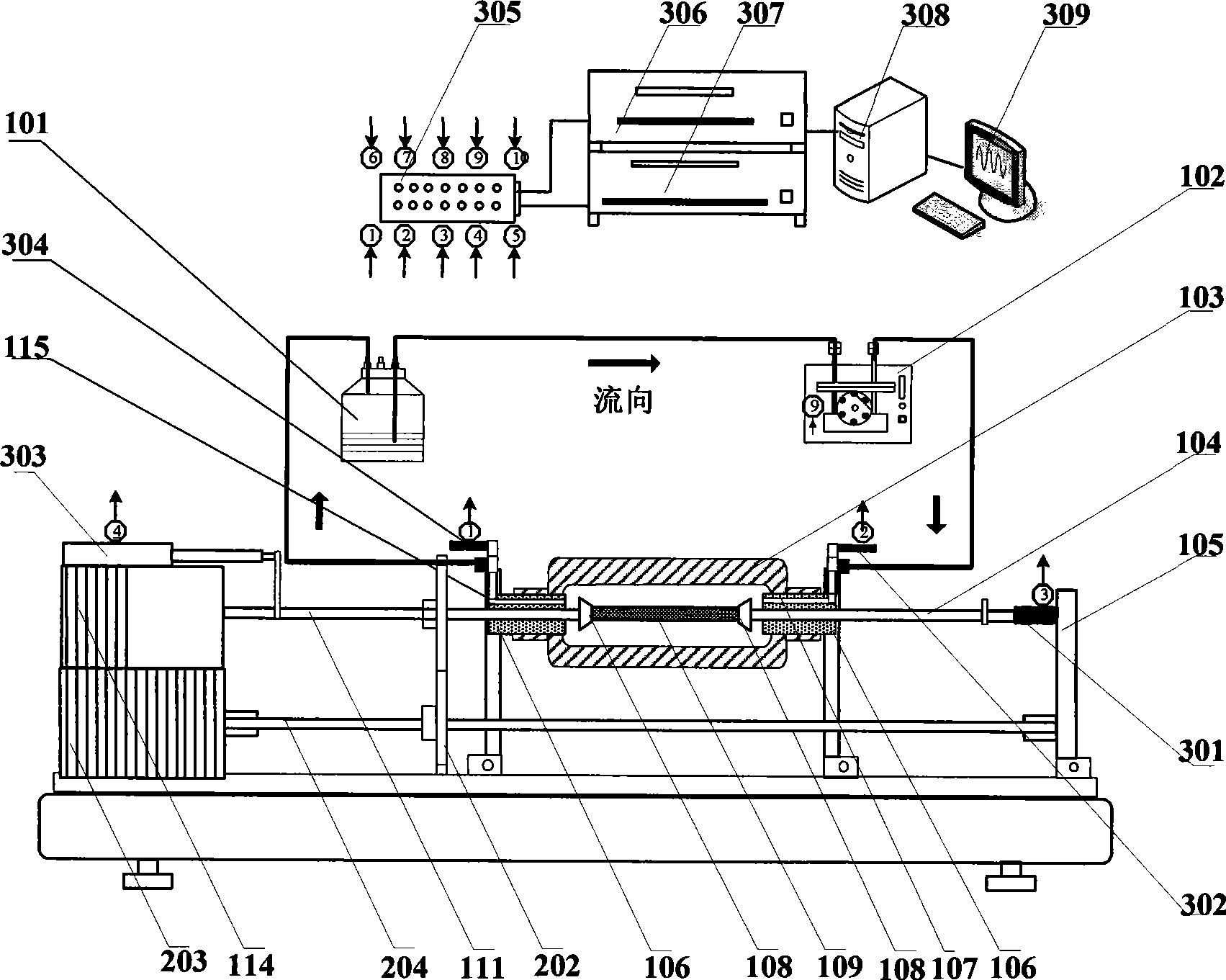

[0079] Example 2 Twisted tension and pressure perfusion belt control system

[0080] 1. According to figure 2 The tissue culture cavity perfusion circuit is connected as shown, wherein the liquid driving device is a peristaltic pump (Cole-Parmer Company, Masterflex series);

[0081] 2. Sterilize the reactor, the disinfection conditions are: 130°C, 3 atmospheres, 1 hour;

[0082] 3. Install the bone tissue culture to be cultured on the jig in the tissue culture chamber in a sterile state, wherein the bone tissue culture has a diameter of 4 mm and a length of 5 cm, and the scaffold material is hydroxyapatite;

[0083] 4. According to figure 2 The tissue culture torsion device is connected as shown, wherein the tissue culture torsion motor is a Haydn 57000 series stepper motor;

[0084] 5. According to figure 2 The pressure sensor connected to the inlet and outlet of the tissue culture chamber as shown, and the signal detection device;

[0085] 6. According to figure 2 ...

Embodiment 3

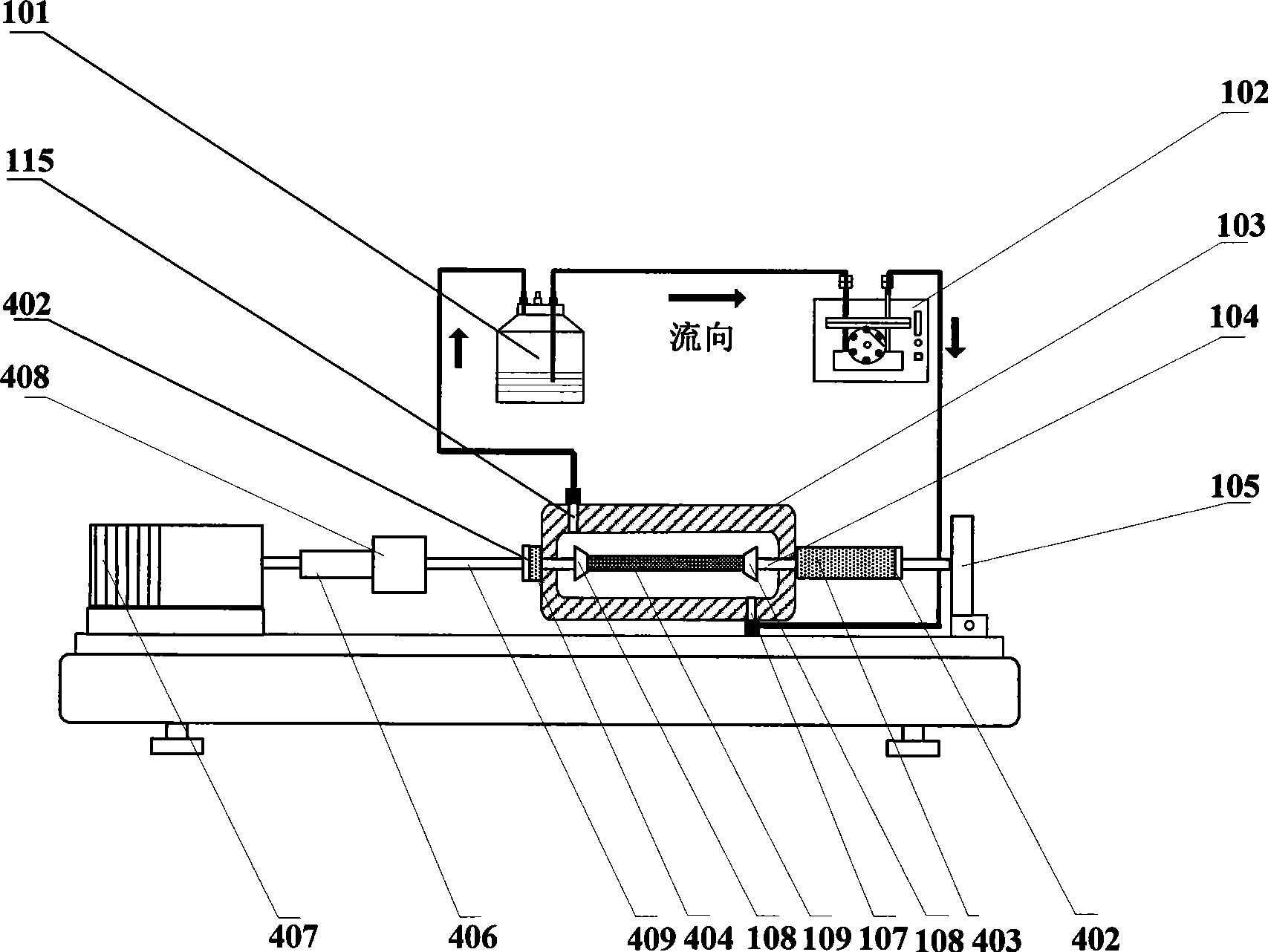

[0093] Example 3 Twisted tension and pressure perfusion belt control system

[0094] 1. According to Figure 4The tissue culture cavity perfusion circuit is connected as shown, wherein the liquid driving device is a peristaltic pump (Cole-Parmer Company, Masterflex series);

[0095] 2. Sterilize the reactor, the disinfection conditions are: 130°C, 3 atmospheres, 1 hour;

[0096] 3. Install the bone tissue culture to be cultured on the jig in the tissue culture chamber in a sterile state, wherein the bone tissue culture has a diameter of 4 mm and a length of 5 cm, and the scaffold material is hydroxyapatite;

[0097] 4. According to Figure 4 The connection tissue culture tension, compression and twisting device is shown, wherein the tissue culture tension, compression and twisting motor is a dual-motion motor;

[0098] 5. According to Figure 4 The pressure sensor and signal detection device connected to the inlet and outlet of the tissue culture chamber are shown;

[009...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com