Optical cable foaming packing gasket granule material and method for producing same

A foam filling and production method technology, applied in the field of granular materials, can solve the problems of high cost of raw materials, heavy weight of filling rope, no data reports on the production of granular materials, and the availability of real products on the market, and achieve the effect of low raw material cost and good protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

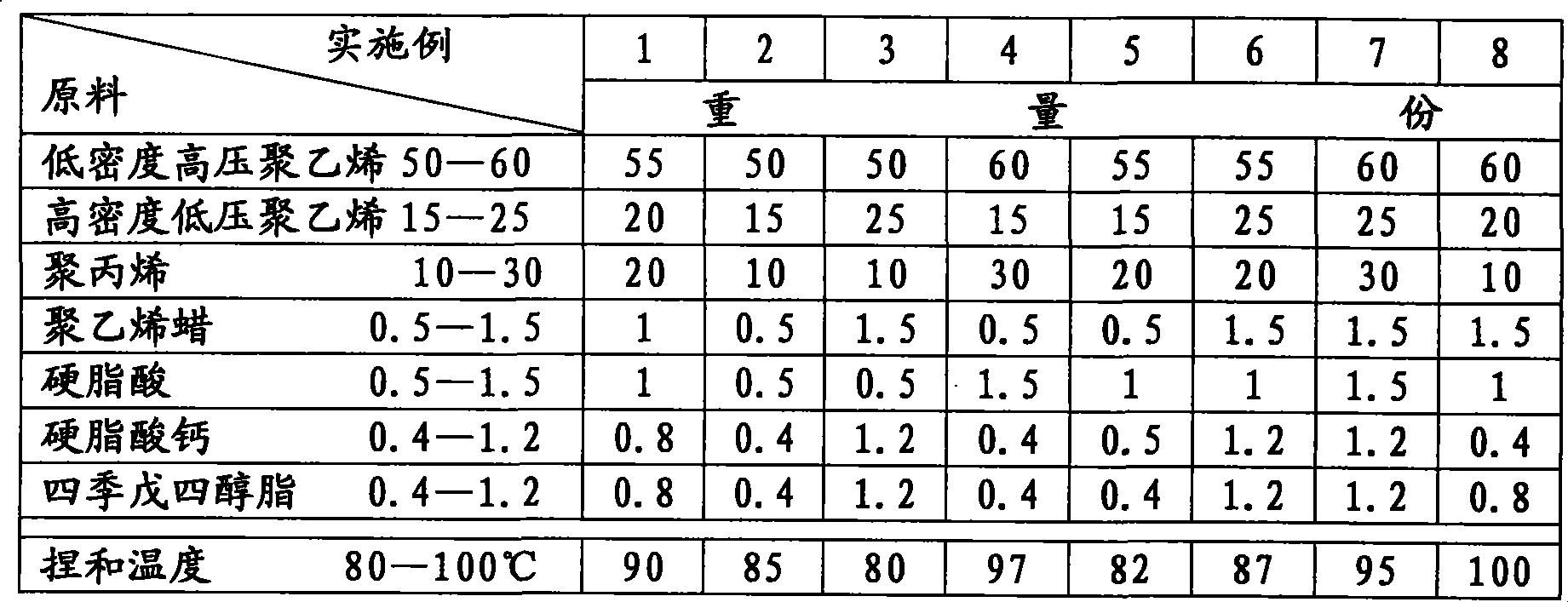

[0012] Embodiment 1 (compared with the corresponding raw materials, parts by weight, and temperature values in the above table): 55 parts of low-density high-pressure polyethylene, 20 parts of high-density low-pressure polyethylene, 20 parts of polypropylene, 1 part of polyethylene wax, 1 part of stearin acid, 0.8 parts of calcium stearate, and 0.8 parts of tetraerythritol fat, and knead them evenly in a kneader at a temperature of 90°C to make a kneaded product, and then send the kneaded product into a twin-screw extruder. Control the temperature of the heating rings arranged in a line in the machine to 200°-300°C from low to high, extrude them into Φ3mm long strips, then enter the cooling tank to cool, dry, and cut into 3mm long strips. Φ2.5mm (shrinkage due to cold) particles, inspection and packaging.

[0013] Examples 2-8 all compared the corresponding raw materials, proportions by weight, and kneading temperature in the table, and granulated in the same way as Example ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com