Aerobic granule sludge membrane bioreactor system

A technology of aerobic granular sludge and membrane bioreactor, applied in the direction of sustainable biological treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve clogging, increase operating costs, widely used, membrane modules Pollution and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

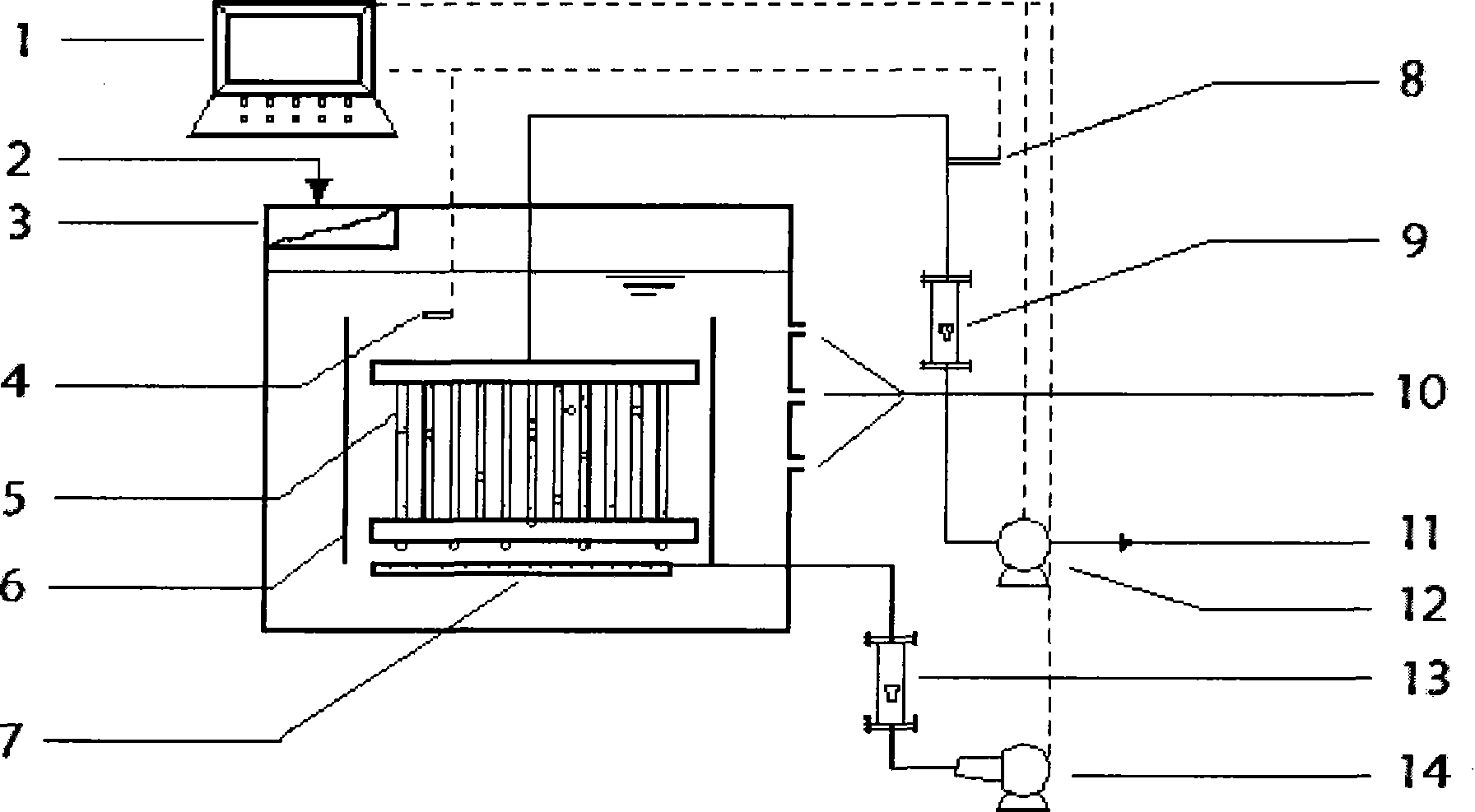

Method used

Image

Examples

Embodiment 1

[0017] Example 1: Granular sludge cultivation of GMBR

[0018] Add activated sludge to the reactor, control the pH between 7.0 and 8.5, and the system COD volume load is between 0.5 and 2.0 kg / m 3 Change between .d, control the amount of aeration, and intermittently drain the finely divided sludge from the drain. After 3-4 days, the polymer with a relatively compact structure appears, and the aerobic granular sludge gradually appears after 8 days. On this basis, by controlling the amount of aeration and sludge discharge, the flocculent sludge with poor settling performance is continuously washed out, and the granular sludge is mainly used in the reactor. After determining the effect of aerobic granular sludge in the reactor on the COD and NH in the wastewater 3 -N has a better treatment effect.

Embodiment 2

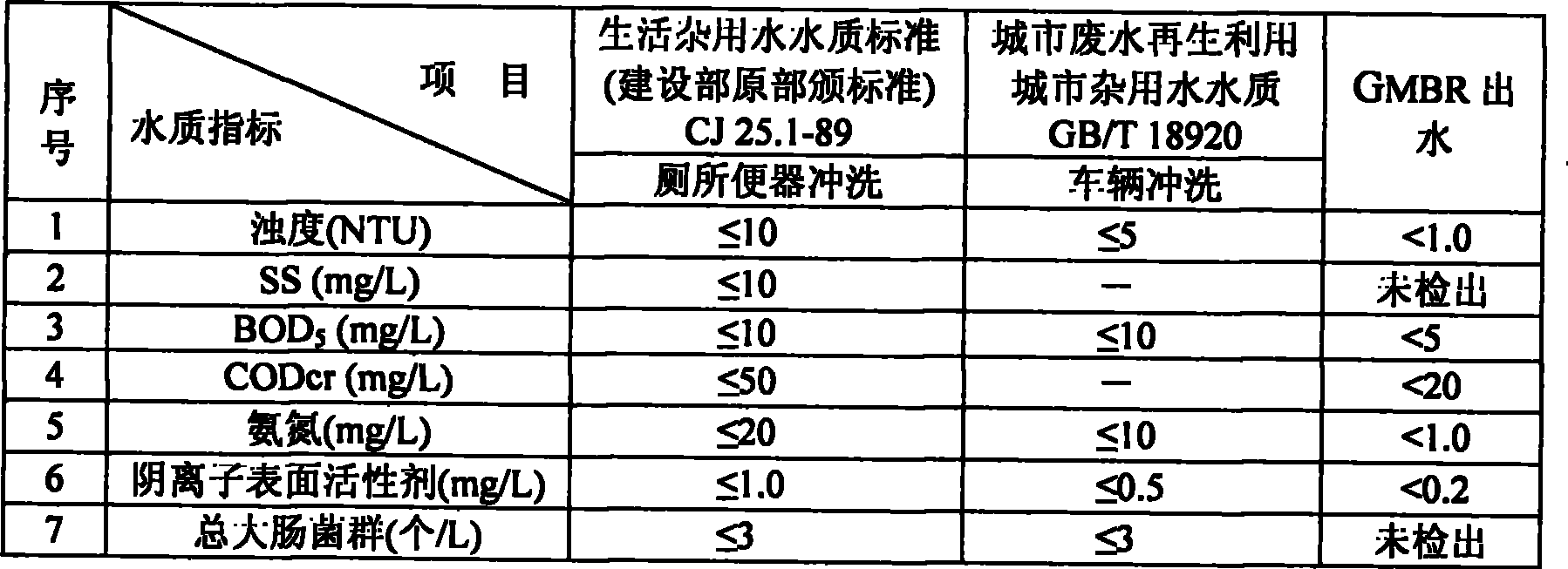

[0019] Example 2: Comparison of GMBR effluent water quality with relevant national standards

[0020] The effluent quality of domestic sewage treated with GMBR is better than the standard of water reuse (toilet flushing and vehicle flushing) formulated by the state and relevant departments.

[0021]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com