Anaerobic reactor for processing high organic concentration and high solid content waste water

An anaerobic reactor and solid content technology, which is applied in the field of anaerobic reactors, can solve the problems that high-efficiency anaerobic reactors cannot handle waste water with high solid content, achieve good phase separation characteristics, reduce engineering costs, good environmental benefits and The effect of economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

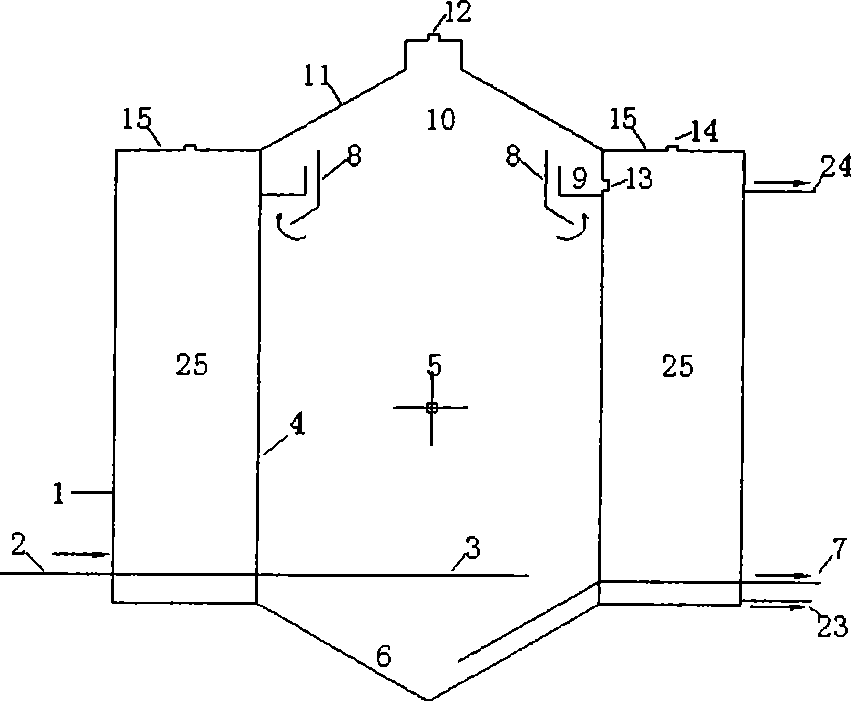

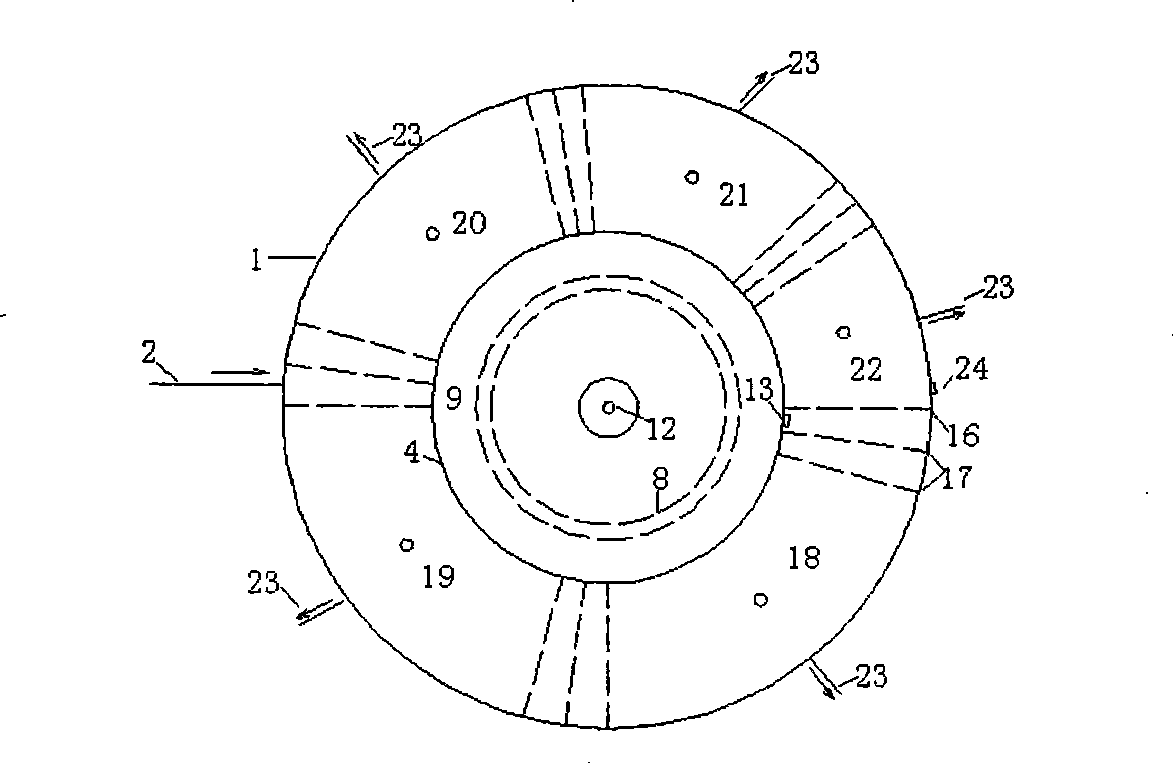

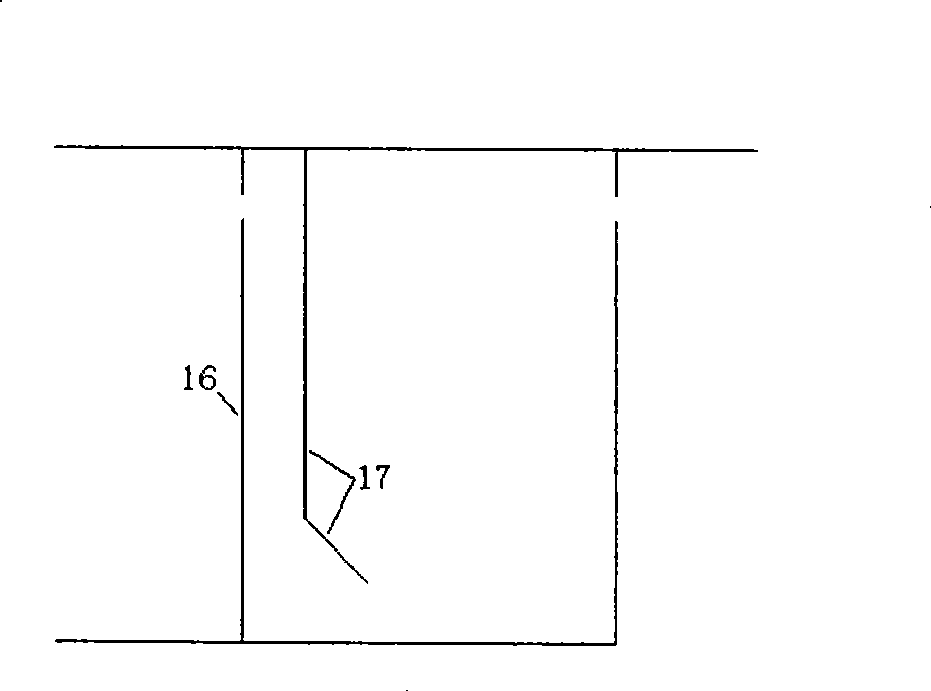

[0017] As shown in the drawings, the main body of the reactor 1 is cylindrical, and is divided into a high solid reaction zone 5 and a baffle reaction zone 25 . The lower part of the high solid reaction area 5 is provided with a water inlet pipe 2 and a water distribution system 3, and the bottom is provided with a sludge sedimentation area 6 and an intermittent sludge discharge pipe 7, and the upper part is provided with a slag retaining plate 8 and a water collection tank 9 around the edge, and the upper part is a gas collection The chamber 10 is provided with a sealing cover 11 and an air collecting pipe 12 at the top. The baffle reaction zone 25 is divided into five or six compartments (five compartments shown in the figure), the first compartment 18, the volume of the second compartment 19 are larger, the third compartment 20, the fourth compartment The volumes of the compartment 21 and the fifth compartment 22 decrease successively, forming compartments in series with ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com