Pole plate for battery pack

A battery pack and plate technology, applied in battery pack components, electrode carriers/current collectors, circuits, etc., can solve the problem of poor electrical connection of different materials, informatization that cannot meet urban public transportation, and affect the service life of battery packs and other problems, to avoid welding problems, solve cost-effectiveness, safety and durability, and equalize the current flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Domestic electric vehicles generally use lithium manganese oxide batteries with a large capacity of 50-100A or more that cannot be mass-produced in parallel and connected in series, which cannot meet the basic needs of urban public transportation in terms of safety, reliability, durability, and the degree of informatization of the control system. When using lithium iron phosphate high-capacity single battery with high safety factor, the electrical connection between the plate and the battery often affects the service life of the battery. Therefore, a new battery pack plate is proposed.

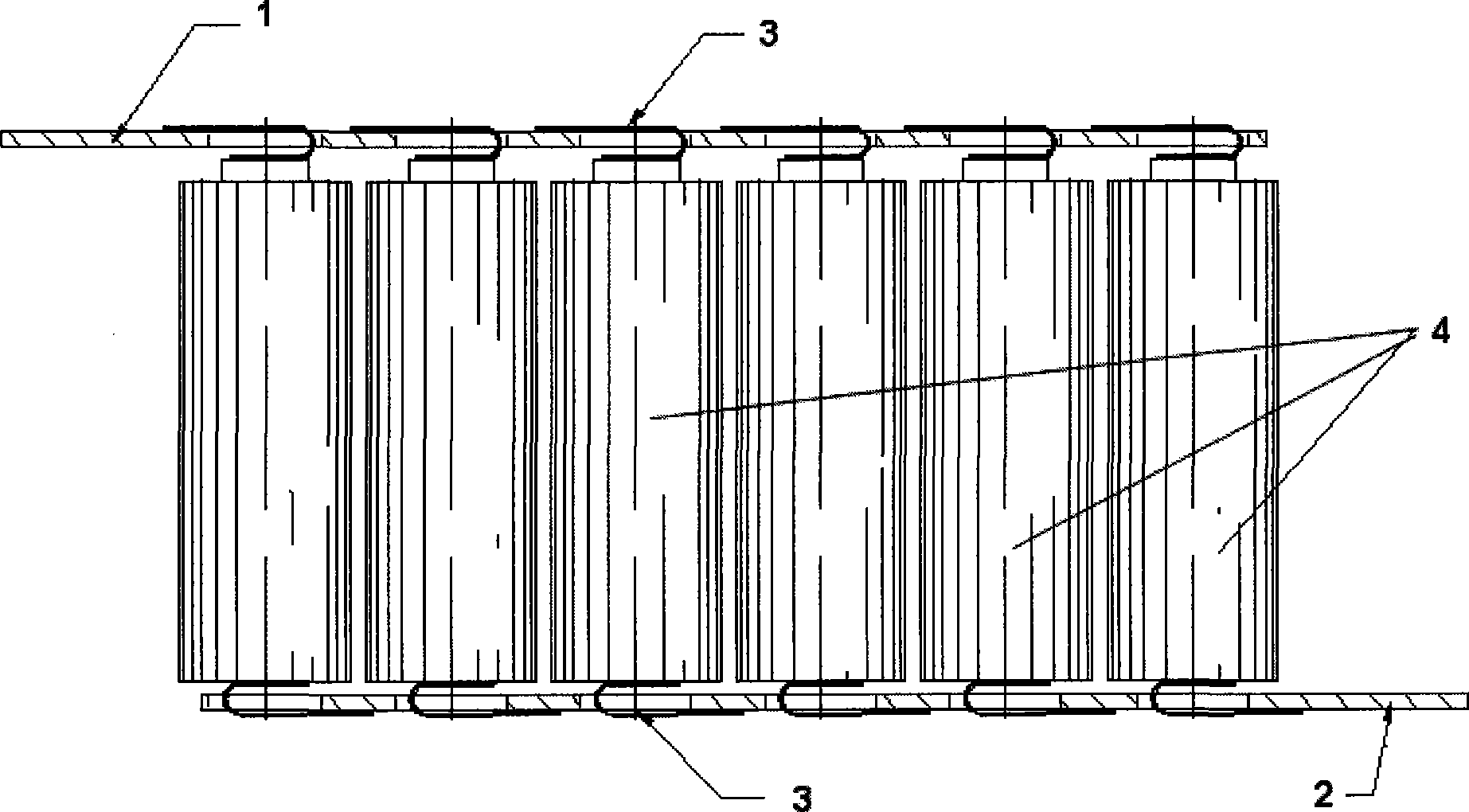

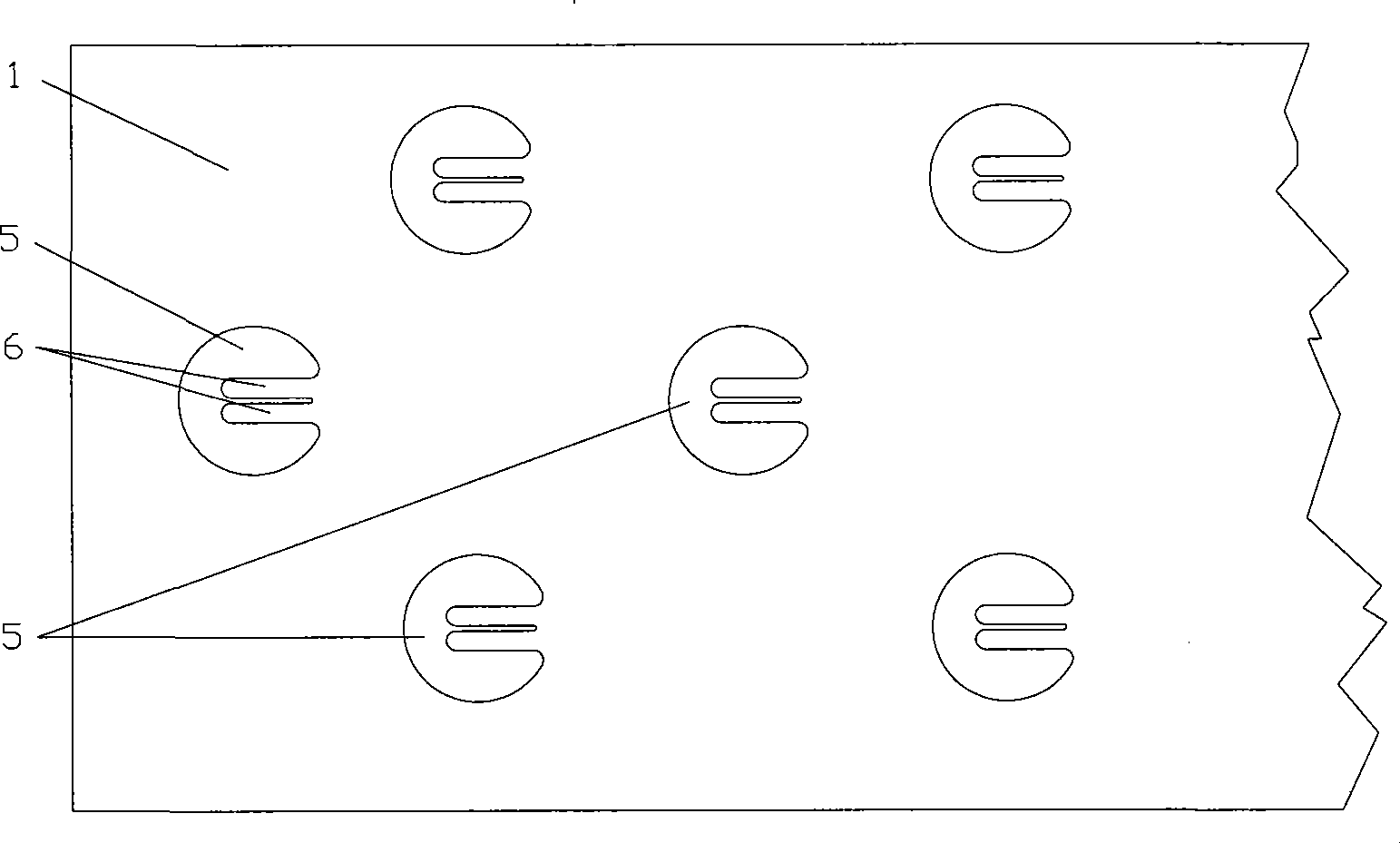

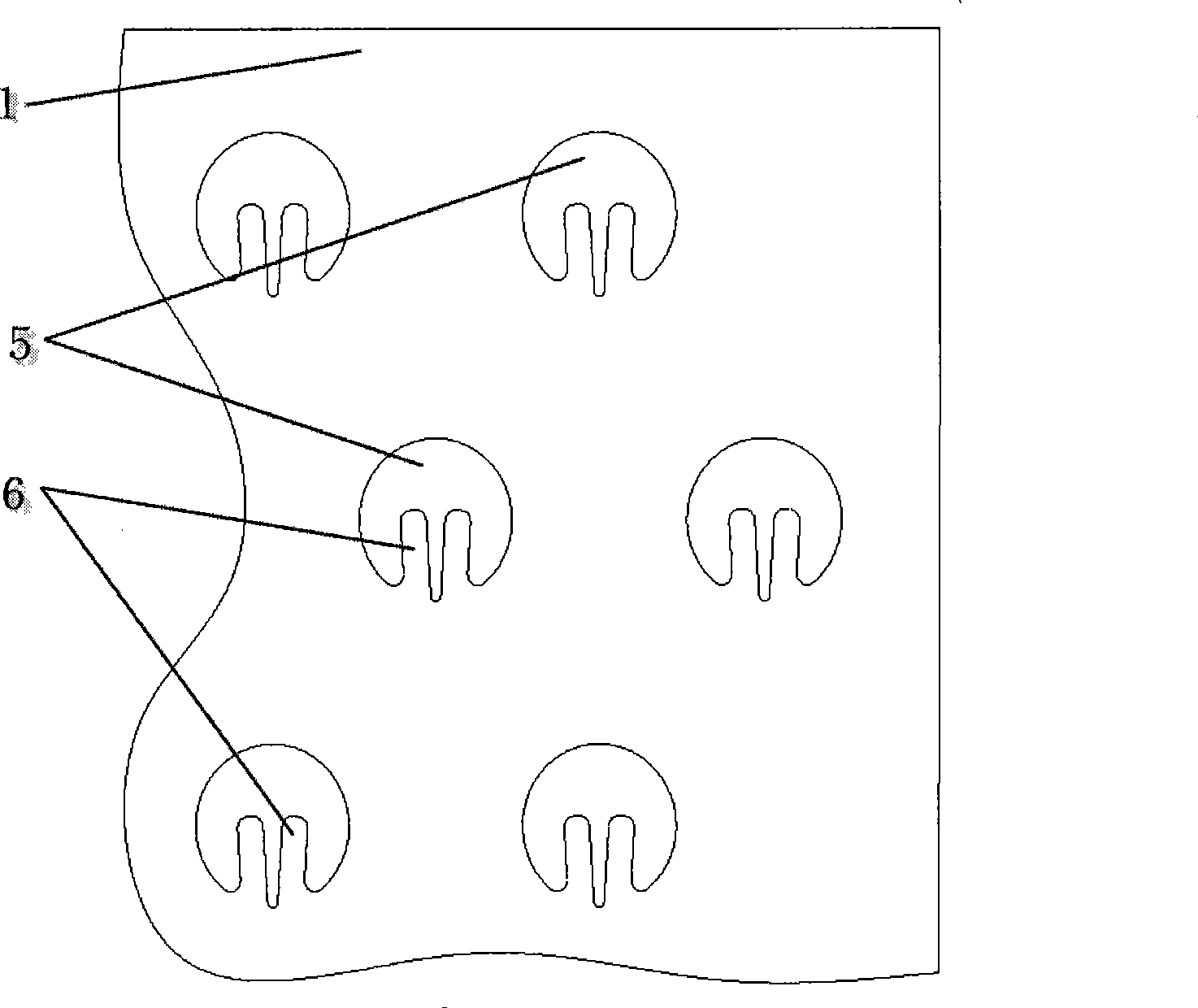

[0019] Such as figure 1 As shown in , the interior of the power battery pack is composed of an anode plate 1, a cathode plate 2 and a tab 3 welded on the plate, and the anode plate (bus bar) 1 and the cathode plate (bus bar) A plurality of batteries 4 are placed between the 2, and the batteries 4 can adopt a cylindrical (or cubic or rectangular) lithium iron phosphate high-capacity sing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com