Method for producing nonwoven gridding reinforced composite nonwoven fabrics

A technology for enhancing compounding and manufacturing methods, applied in non-woven fabrics, textiles and papermaking, etc., can solve the problems of increased manufacturing costs and raw material costs, low weaving efficiency of binding threads, and inability to be applied in large quantities, achieving high production efficiency and changing Forming method and bonding method, the effect of improving physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

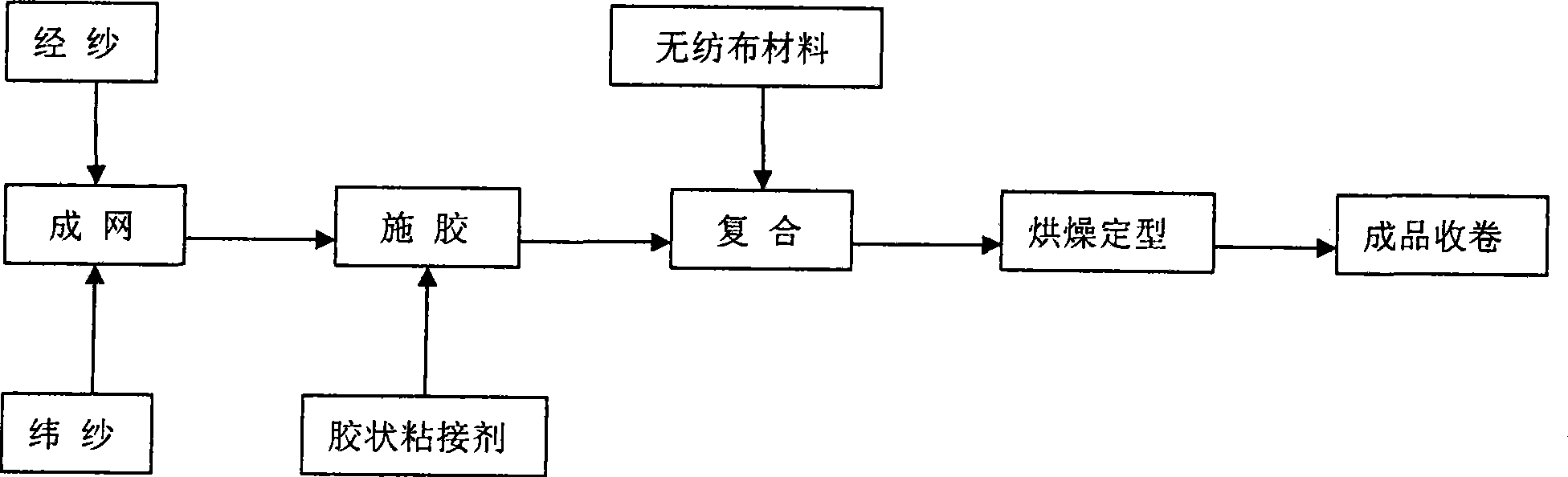

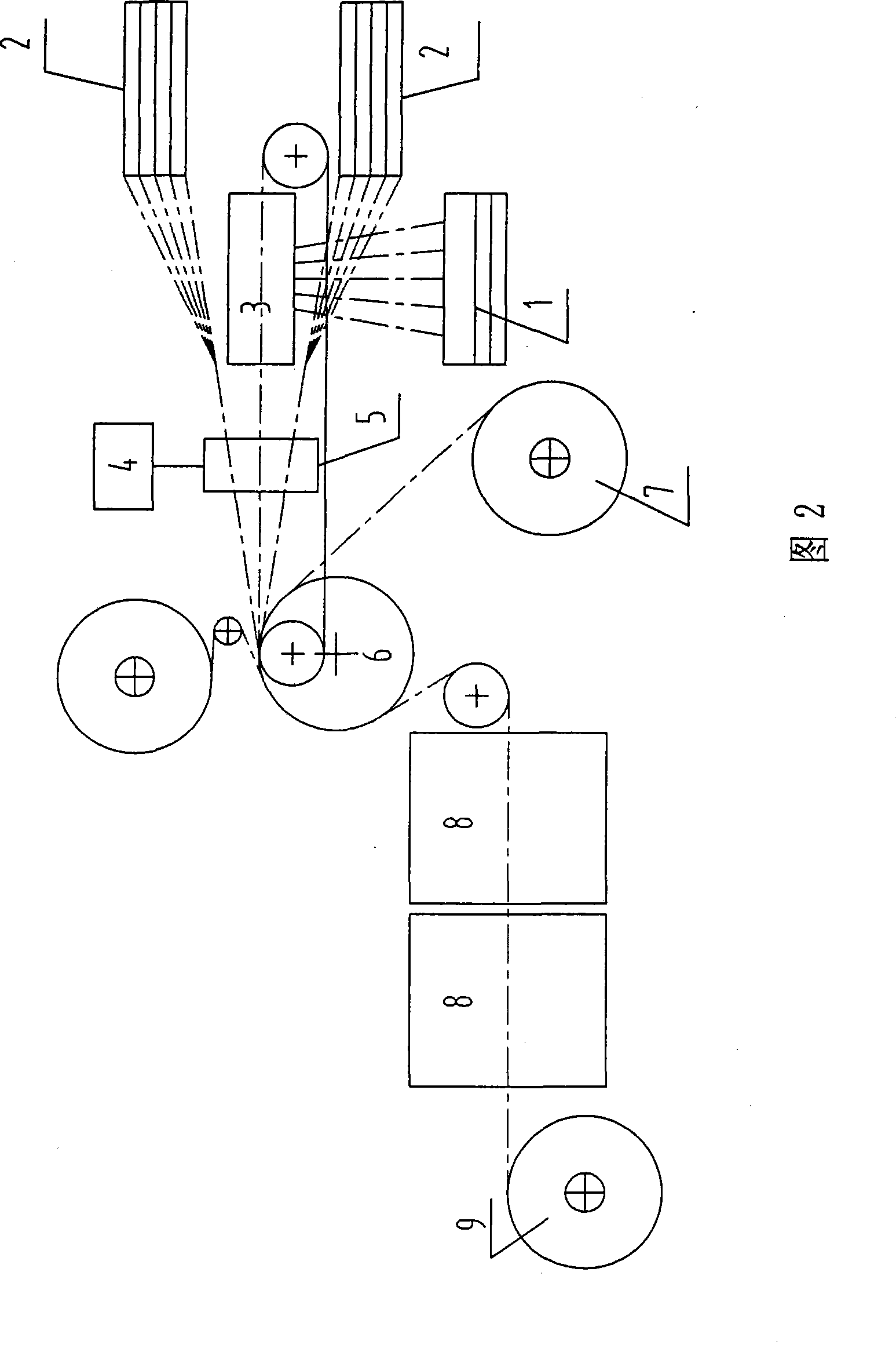

Method used

Image

Examples

Embodiment 1

[0027] ①Using glass fiber as warp yarn (alkali-free 68Tex) and weft yarn (alkali-free 136Tex), use a weft laying device to draw the weft yarn from the weft yarn creel, and hang it in parallel on the chain hook of the weft laying device without interruption. The weft yarns of the non-woven mesh are arranged in parallel, and the forward speed of the chain hook and the composite drum are carried out at a relative speed difference, and the speed difference ratio is 3 times.

[0028] ② At the same time, the warp yarns are drawn out from the warp yarn creel, perpendicular to the weft yarns, and arranged neatly; the arrangement density of the warp yarns is 4 yarns / cm, and the warp yarns are introduced into the composite point of the composite drum in one layer, and the speed of its extraction is basically synchronized with the composite drum , the line speed is 8M / min.

[0029] ③The method of spraying glue is used for sizing, so that the acrylic hydrosol is evenly distributed on the ...

Embodiment 2

[0035] ①Using carbon fiber as the warp yarn (alkali-free 68Tex) and weft yarn (alkali-free 136Tex), use the weft laying device to draw the weft yarn from the weft yarn creel, arrange it in parallel and hang it on the chain hook of the weft laying device without interruption, so as to realize non-alkali The weft yarns of the weaving grid are arranged in parallel, and the forward speed of the chain hook and the compound drum are carried out with a relative proportional speed difference, and the speed difference ratio is 2 times.

[0036] ②At the same time, the warp yarns are drawn out from the warp yarn creel, and arranged vertically to the weft yarns; the arrangement density of the warp yarns is 3 threads / cm; the warp yarns are introduced into the composite point of the composite drum in two layers, and the speed of the introduction is basically synchronized with the composite drum , the line speed is 18M / min.

[0037] ③ Sizing is carried out by dipping, so that the acrylic hyd...

Embodiment 3

[0043] ①Using polyester fibers as warp yarns (alkali-free 68Tex) and weft yarns (alkali-free 136Tex), use a weft laying device to draw the weft yarns from the weft yarn creel, and hang them in parallel on the chain hooks of the weft laying device without interruption. To realize the parallel arrangement of the weft yarns of the non-woven mesh, the forward speed of the chain hook and the composite drum are carried out at a relative speed difference, and the speed difference ratio is 2 times.

[0044] ② At the same time, the warp yarns are drawn out from the warp yarn creel, and arranged vertically to the weft yarns; Synchronously, its line speed is 10M / min.

[0045] ③The method of spraying glue is used for sizing, so that the wood glue is evenly distributed on the warp and weft yarns.

[0046]④The gel-like adhesive on the warp and weft yarns is still in a wet state, and is composited with the non-woven material on the composite drum, and the non-woven material is composited in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com