Steel plate automatic detection method and apparatus thereof based on electromagnetical ultrasonic SH wave technology

An automatic detection device, electromagnetic ultrasonic technology, applied in the direction of using sonic/ultrasonic/infrasonic waves to analyze solids, can solve problems such as inability to effectively detect cracks and small defects, achieve high detection accuracy and real-time performance, strong environmental adaptability, eliminate The effect of detecting blind spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

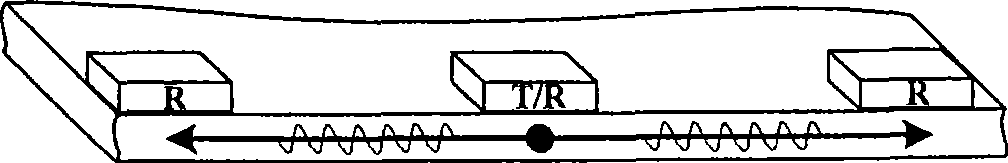

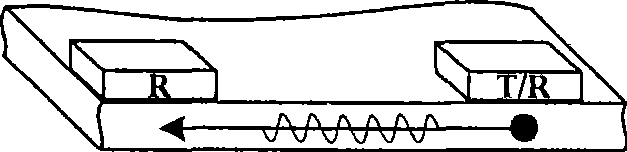

[0035] Embodiment 1, combining figure 1 , figure 2 , the use of electromagnetic ultrasonic technology can directly excite horizontally polarized shear waves in the steel plate under test, also known as SH waves (Shear Horizontal Wave). The dispersion characteristic of SH wave is simpler than that of Lamb wave, and SH wave is not easy to undergo mode conversion after being reflected by defects or end faces, and the received signal is pure, which is suitable for detecting the position and shape of various defects. In addition, since electromagnetic ultrasonic technology does not require acoustic coupling agents and pretreatment of specimens during detection, SH waves generated by electromagnetic ultrasonic technology can be used for on-line or in-service detection of medium and thin plates in various harsh environments.

[0036] In order to realize the electromagnetic ultrasonic automatic detection of medium and thin plates, the solution to the technical problem of the present...

Embodiment 2

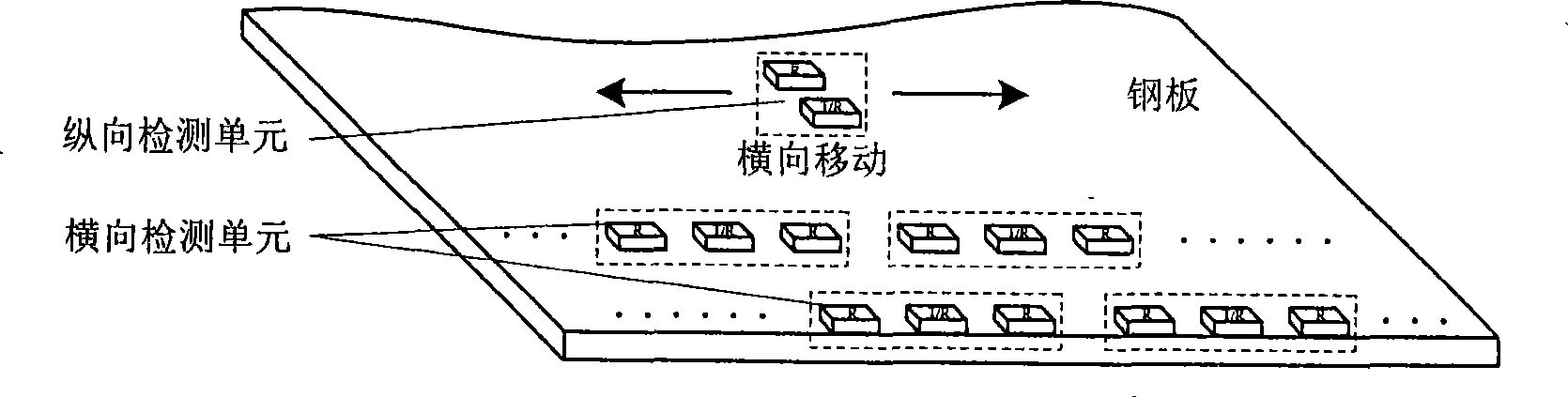

[0037] Example 2, combined with image 3, the microprocessor periodically generates the SH wave control signal, and stimulates the transceiver integrated probe in the detection unit to generate the SH wave in the steel plate. Ultrasound propagates in the steel plate, and when it encounters a defect or an end face, it is reflected and scattered. The reflected signal and the transmitted signal can be received by the transceiver integrated probe and the transmitted wave receiving probe respectively. The steel plate automatic detection device based on the electromagnetic ultrasonic SH wave technology collects the received signal and processes the digital signal under the control of the microprocessor. The shape and position of the defect can be judged by comprehensively analyzing the reflection and transmission signals, and the detection results can be displayed in real time by the display circuit. In the present invention, the detection units are arranged in a combination of ho...

Embodiment 3

[0038] Example 3, combined with Figure 4 , Figure 5 , there are currently two options for generating SH waves. The first scheme is that the electromagnetic ultrasonic coil adopts a meander coil, and the static magnetic field is a horizontal magnetic field parallel to the coil. The excitation method is as follows: Figure 4 shown. Among them, the meandering coil is made of plexiglass skeleton, which greatly enhances the wear resistance of the probe. The wavelength of the excited SH wave is related to the turn spacing of the meander coil, if the wavelength of the SH wave is λ, then there is

[0039] λ=2l

[0040] In the formula, l——the turn spacing of the zigzag coil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com