Production method of milk rich in galacto-oligosaccharides

A technology of galacto-oligosaccharides and production methods, which is applied in the direction of dairy products, milk preparations, food preparation, etc., can solve problems such as the decline of lactase activity, reduce production costs, solve lactose intolerance, and simplify cleaning and disinfection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1. The method of immobilizing β-galactosidase: first take a certain amount of particles with hydrazide groups, then add glutaraldehyde with a concentration of 2% and let it stand for 0.5-1 hour, the hydrazide groups of the carrier React with the aldehyde group of glutaraldehyde to generate an activated carrier, then wash the glutaraldehyde remaining on the activated carrier with sterile water, add β-galactosidase and let it stand for 2-4 hours, the aldehyde group of the activated carrier and β- Amino groups of galactosidase are combined to form immobilized β-galactosidase, and the remaining β-galactosidase is washed with sterile water to obtain immobilized β-galactosidase. Among them, the activity of the immobilized enzyme β-galactosidase is 60u / g.

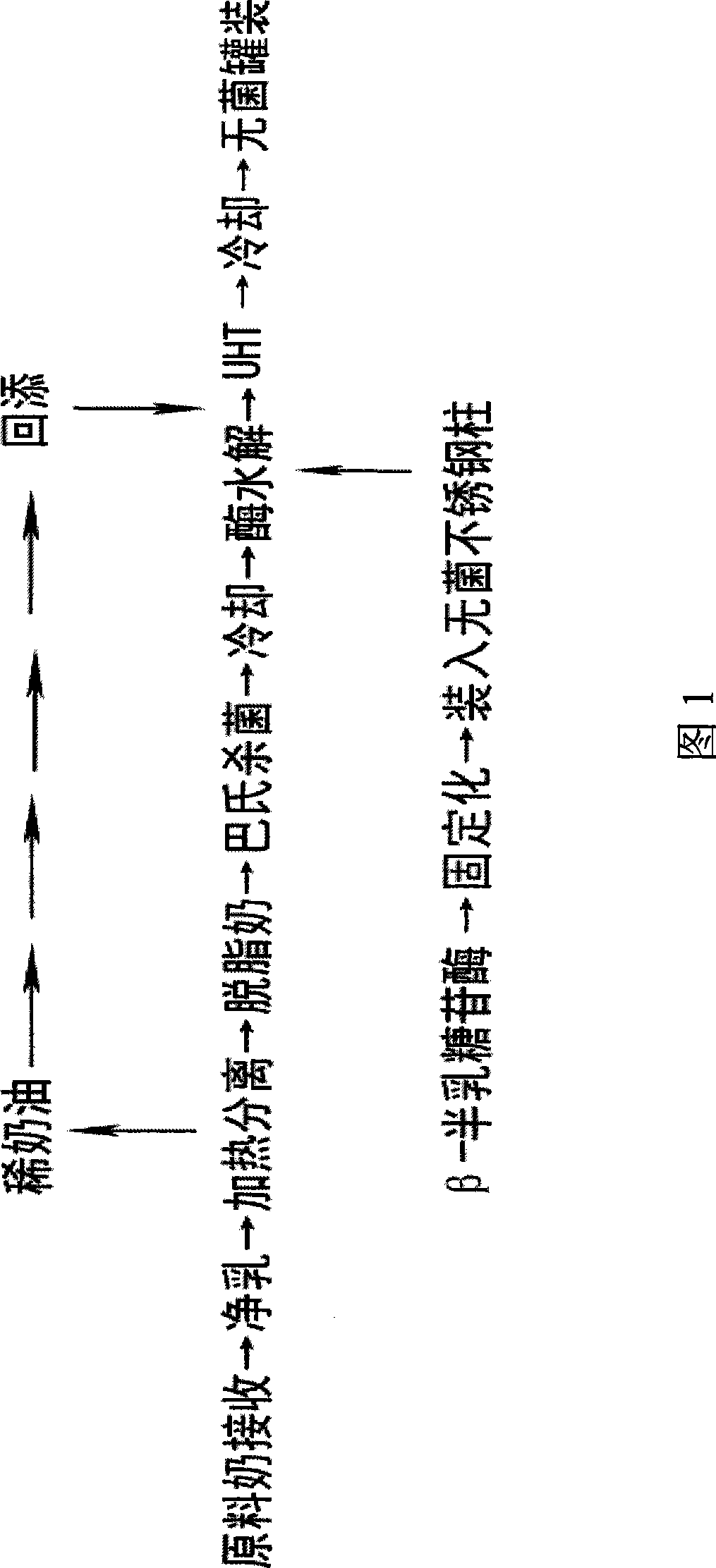

[0038] 2, referring to Fig. 1, the present embodiment provides a kind of production method of above-mentioned galacto-oligosaccharide milk, comprises the steps:

[0039] (1) Clean the raw milk and cool it to 2-8°C for stor...

Embodiment 2

[0049] 1. The same method as in Example 1 was used to prepare immobilized β-galactosidase, wherein the activity of the immobilized enzyme β-galactosidase was 120 u / g.

[0050] 2, the present embodiment provides another kind of production method of above-mentioned galacto-oligosaccharide milk, comprises the steps:

[0051] (1) Clean the raw milk and cool it to 2-8°C for storage;

[0052] (2) heating to 50°C, separating the fat to obtain skim milk, the fat content of which is less than 0.5%;

[0053] (3) Skim milk is pasteurized, the sterilization temperature is 85°C, and it is kept warm for 15Sec; it is cooled to 4°C

[0054] (4) Then pump into the immobilized enzyme reaction column. The reaction column has a diameter of 150mm and a length of 450mm. hydrolysis. The hydrolysis temperature is 4°C, the hydrolysis time is controlled at 180 minutes, and the pH value of the hydrolysis environment is 7.0.

[0055] (5) UHT sterilization, the sterilization temperature is 137°C, the ...

Embodiment 3

[0061] 1. The same method as in Example 1 was used to prepare immobilized β-galactosidase, wherein the activity of the immobilized enzyme β-galactosidase was 150 u / g.

[0062] 2, the present embodiment provides another kind of production method of above-mentioned galacto-oligosaccharide milk, comprises the steps:

[0063] (1) Clean the raw milk and cool it to 2-8°C for storage;

[0064] (2) heating to 50°C, separating the fat to obtain skim milk, the fat content of which is less than 0.5%;

[0065] (3) Skim milk is pasteurized, the sterilization temperature is 85°C, and it is kept warm for 15Sec; cooled to 42°C

[0066] (4) Then pump into the immobilized enzyme reaction column. The reaction column has a diameter of 150mm and a length of 450mm. hydrolysis. The hydrolysis temperature is 42°C, the hydrolysis time is controlled at 90 minutes, and the pH value of the hydrolysis environment is 5.8.

[0067] (5) UHT sterilization, sterilization temperature 137 ℃, holding time 4S,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com