Connection method of filtering filter-core and machine base

A connection method and machine base technology, applied in the direction of loose filter material filter, filtration separation, separation method, etc., can solve the problems of improving the filtering effect, affecting the life of the filter element, clogging, etc., achieving easy quality control, improving product quality, The effect of reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

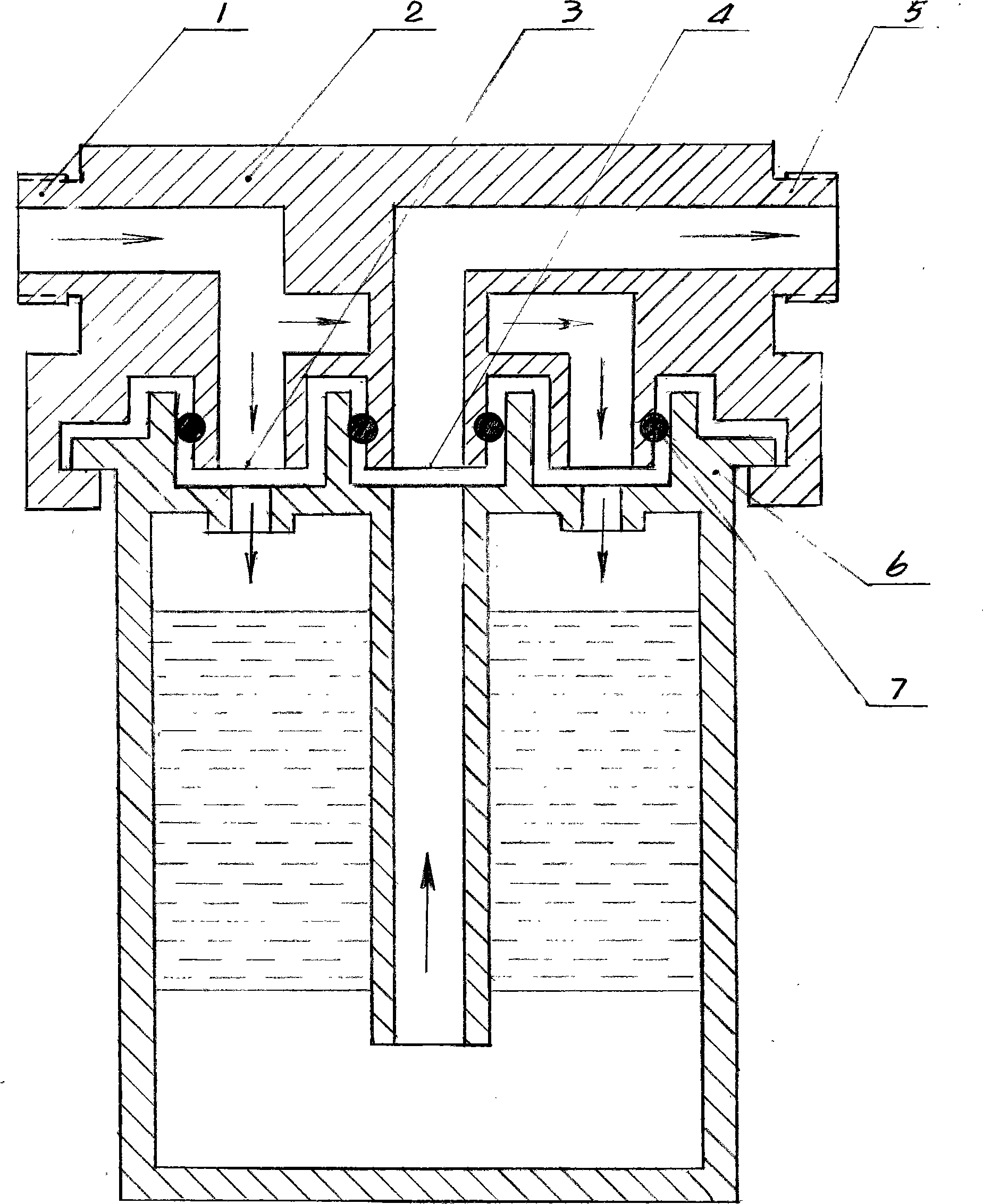

[0017] The preferred embodiment of the invention is shown in the accompanying drawings. The concave-convex disc-shaped water inlet and outlet of the support 2 and the corresponding concave-convex disc-shaped water inlet and outlet on the closed filter element 6 are connected to each other, and are sealed with seals 7 of different sizes to prevent water leakage in each nozzle. The disc-shaped docking nozzle of the support 2 and the filter element 6 is an annular nozzle with the central nozzle of the disc as the center of the circle. The water inlet located on the outer side is a ring-shaped porous structure, which ensures that the central water outlet on the inner side has sufficient connection structure strength to be integrated with the machine base. The group of disc-shaped water ports communicates with the machine base and the water inlet and outlet channels of the filter element, so that the filter element 6 is connected in series between the inlet and outlet pipe interfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com