Method for preparing ethyl trifluoroacetate

A technology of ethyl trifluoroacetate and trifluoroacetic acid, which is applied in the field of preparation of ethyl trifluoroacetate, an organic chemical raw material, to achieve the effects of convenient operation, reduced production cost, and no environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

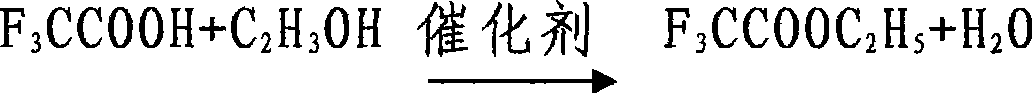

Method used

Image

Examples

Embodiment 1

[0010] According to the mass ratio 1:0.8 of trifluoroacetic acid and anhydrous acetic acid, 500 grams of metered trifluoroacetic acid are put into the esterification reaction device, and 400 grams of dehydrated alcohol are put into the high-level drip metering tank, and then the mass ratio of trifluoroacetic acid and catalyzer is 1: 0.6 Measure 300 grams of 732 type strongly acidic cation exchange resin into the esterification reaction device. Start stirring, raise the temperature to 40°C and start adding absolute ethanol dropwise at a rate of 0.30g-0.80g / s, and control the temperature of the reaction solution between 40°C-50°C. After the dropwise addition, keep stirring at 40° C. to 50° C. for 10 minutes. The temperature was raised to reflux for esterification. The end point of the esterification reaction is controlled with the water in the water separator of the esterification reaction device reaching a theoretical calculation value of 78.9ml, and the esterification reactio...

Embodiment 2

[0013] According to the mass ratio 1:3.2 of trifluoroacetic acid and absolute ethanol, 50 kg of trifluoroacetic acid is put into the esterification reaction device, and 270 grams of the residual high boiling point of embodiment 1, that is, 0.27 kg, is put into the high-level dripping metering tank, and the calculation should be put into Dehydrated alcohol is 160kg, deducts the ethanol amount 0.269kg in the residual high boiling of throwing embodiment 1, throws dehydrated alcohol 159.73kg again and enters the high position dropwise metering tank. Then measure 40 kg of D72 type strongly acidic cation exchange resin according to the mass ratio of trifluoroacetic acid and catalyst of 1:0.8, and put it into the esterification reaction device. Start stirring, raise the temperature to 45°C and start adding absolute ethanol dropwise at a rate of 0.4g~0.6g / s, control the temperature of the reaction solution between 45°C~49°C, keep stirring at 45°C~49°C for 10 minutes after the addition ...

Embodiment 3

[0016] According to the mass ratio of trifluoroacetic acid and dehydrated alcohol 1:1.8, measure 150kg of trifluoroacetic acid and put it into the esterification reaction device, first put the residual high boiling 144.7kg of embodiment 2 into the high-level dripping metering tank, and calculate that it should be dropped into dehydrated ethanol 270kg, subtracted the ethanol amount 144.35kg in the residual high boiling of throwing embodiment 2, throws dehydrated ethanol 125.65kg again and enters the high position dripping metering tank. Then measure 45 kg of 732 type strongly acidic cation exchange resin according to the mass ratio of trifluoroacetic acid and catalyst of 1:0.3, and put it into the esterification reaction device. Start stirring, raise the temperature to 46°C and start adding absolute ethanol dropwise at a rate of 0.45g-0.55g / s, control the temperature of the reaction solution between 46°C-48°C, keep stirring at 46°C-48°C for 10 minutes after the addition . The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com