Double-crank shaft engine

A technology of engine and double crankshaft, which is applied in the direction of machines/engines, mechanical equipment, one-way clutches, etc., can solve problems such as large crankshaft, reduced fuel consumption, increased engine effective power and torque, etc., to increase the length of the arm and reduce the Fuel consumption, effect of improving effective power and torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

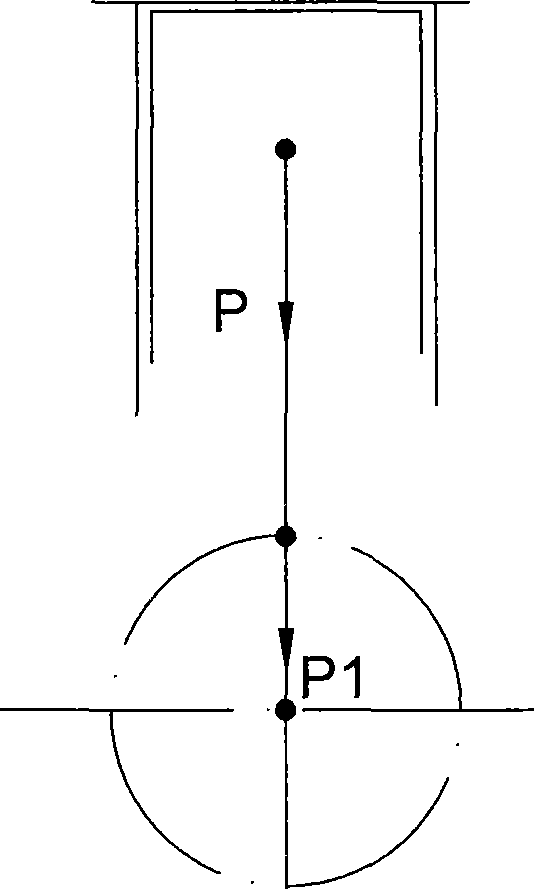

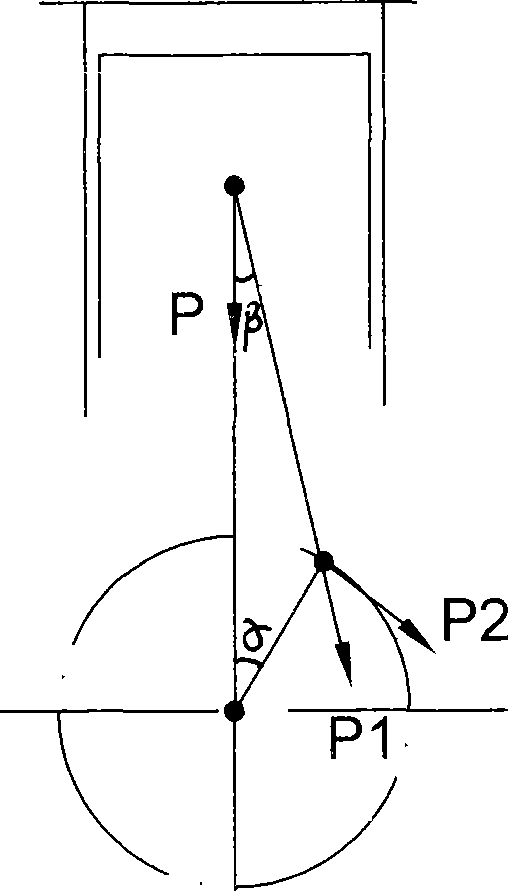

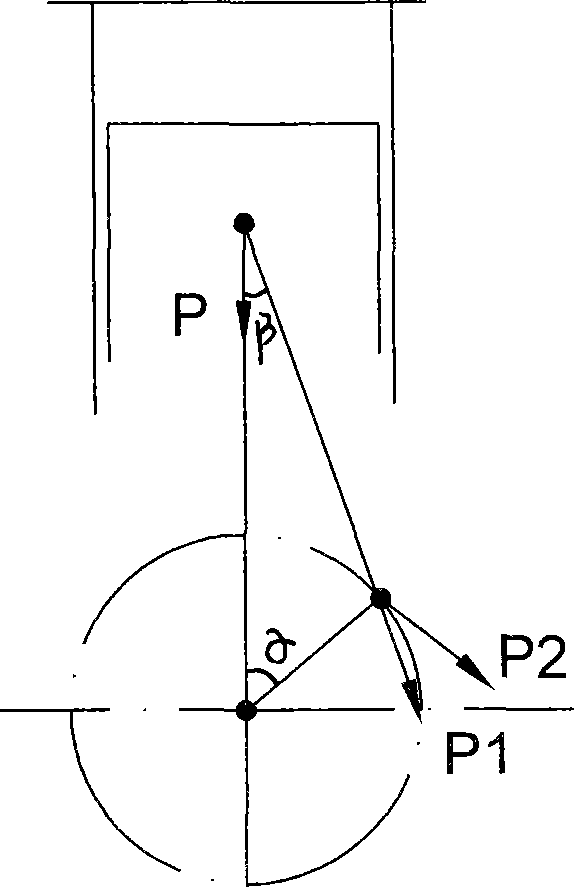

[0017] Such as Figure 4 Shown, a kind of dual crankshaft engine comprises a cylinder (6) and a piston (4) assembled in the cylinder (6), and the top of the cylinder (6) is closed with a cylinder head (2). On cylinder head (2), be equipped with inlet and exhaust device (1) and fuel supply device (not shown in the figure), if ignition type engine also comprises a spark plug (3) of timely ignition. Piston (4) is hinged with the upper end of connecting rod (7) through piston pin (5). Wherein the cylinder (6), piston (4), connecting rod (7), cylinder head (2) and the intake and exhaust device (1) and fuel supply device, spark plug (3) on the cylinder head (2), its structure And the cooperative relationship between each part is the same as the prior art, so I won't repeat it here.

[0018] Figure 4 In, also comprise a crankcase (8), a crankshaft (18) is supported and assembled in the crankcase (8) by the bearing (17), the feature of the present invention is: the crank pin (19) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com