Polarizing plate, manufacturing method therefor, optical film and image display

A polarizing plate and film technology, applied in the field of polarizing plate and its manufacturing, can solve the problems of polarizing plate size change and unevenness, and achieve the effects of improving adhesive force, suppressing delamination, and high-speed production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0171] (Adhesive: curable component)

[0172] As the adhesive, N-hydroxyethylacrylamide was used.

[0173] (formation of easy-adhesive layer)

[0174] With respect to 100 parts by weight (solid content) of a polymer having a polyester skeleton (Superflex SF210, manufactured by Daiichi Kogyo Pharmaceutical Co., Ltd.), 10 parts by weight of 3-acryloyloxypropyltrimethoxysilane (KBM5103, Shin-Etsu Silicone Co., Ltd.), a forming material was prepared (solid content concentration: 11% by weight). Using a bar coater, apply this forming material to one side of a transparent protective film (lactone ring polymethyl methacrylate film) to a thickness of 0.3 μm, dry at 150°C, and form an easy Adhesive layer.

[0175] (Formation of polarizing plate)

[0176] Using a micro-gravure coating machine (gravure printing roll: #300, rotation speed 140% / line speed), on the easy-adhesive layer formed on the transparent protective film, apply the adhesive to form a thickness of 5 μm transparent ...

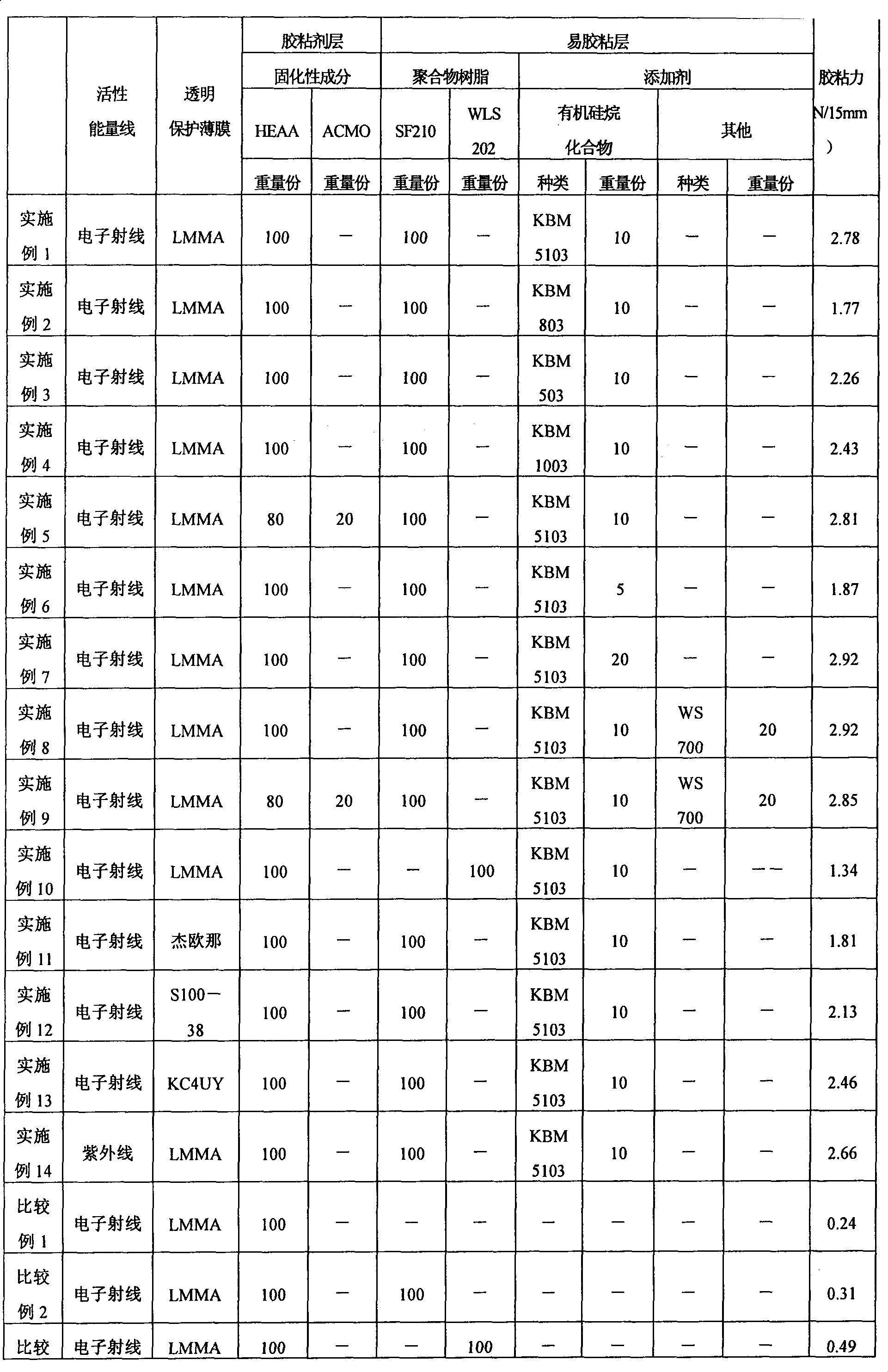

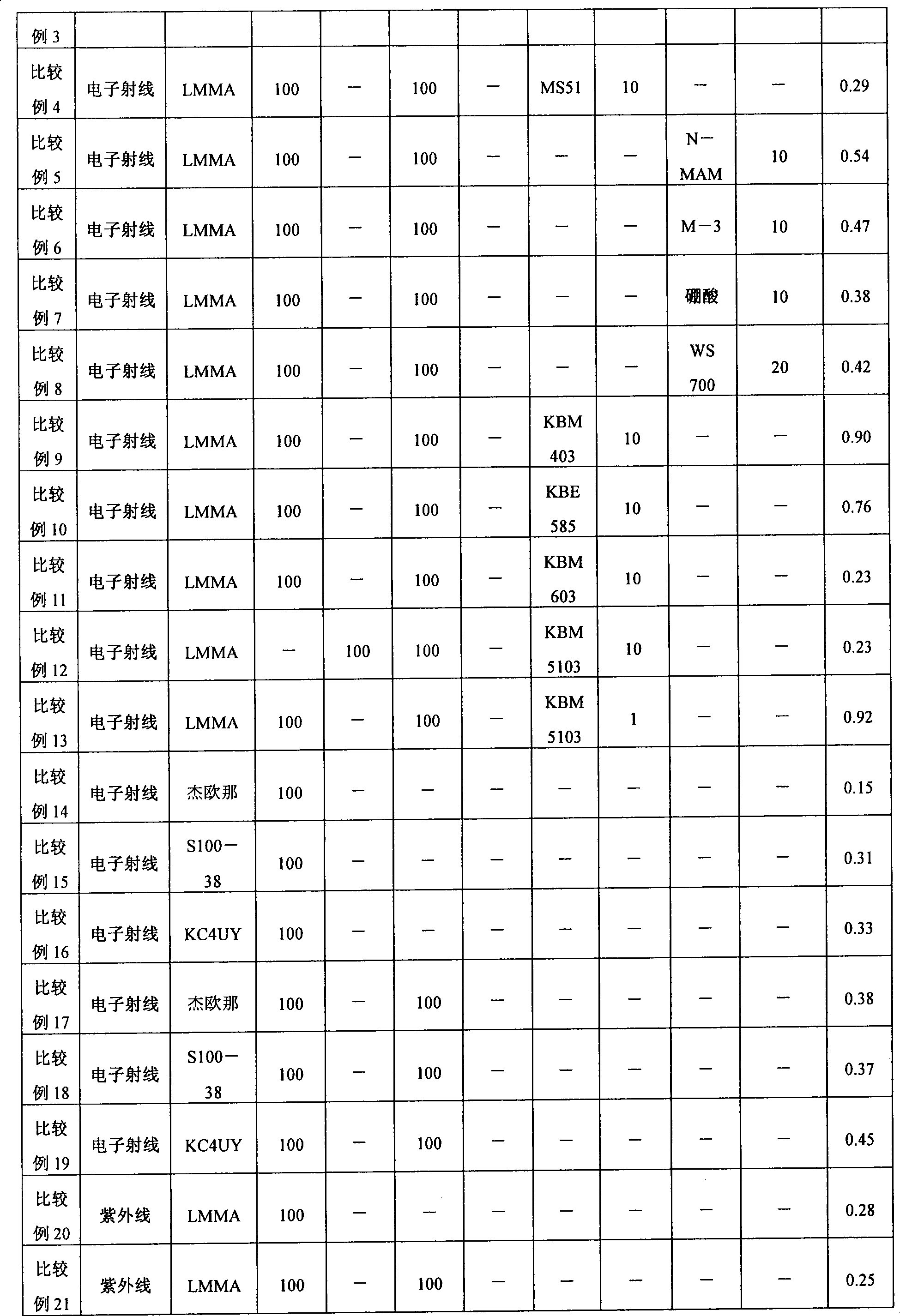

Embodiment 2~13、 comparative example 1~19

[0178] In Example 1, the type of transparent protective film, the type of adhesive (curable component), and its ratio when used in combination; the type of polymer resin forming the easy-adhesion layer, the type of additives, or their usage amounts are shown in Table 1. As shown, except this, it carried out similarly to Example 1, and obtained the polarizing plate.

Embodiment 14

[0180] (Adhesive: curable component)

[0181] 3 parts by weight of a photopolymerization initiator (manufactured by Chiba Special Chemicals Co., Ltd.; trade name Irgacure 127) was mixed with 100 parts by weight of N-hydroxyethylacrylamide, and used as an adhesive.

[0182] (Formation of polarizing plate)

[0183] Carry out in the same manner as in Example 1 (formation of an easily-adhesive layer), using a micro-gravure coating machine (gravure printing roll: #300, rotation speed 140% / line speed), on a transparent protective film (lactonization On the easy-adhesive layer formed on the polymethyl methacrylate film), the adhesive prepared in the above was coated to form a transparent protective film with an adhesive with a thickness of 5 μm. Next, the transparent protective film with an adhesive was bonded from both sides of the polarizing plate by a rolling mill. Ultraviolet rays were irradiated from the side (both sides) of the bonded transparent protective film to obtain a p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com