Fresh-keeping method for bramble and antistaling agent used before picking

A preservative and raspberry technology, which is applied in the fields of fruit and vegetable preservation, food preservation, food science, etc. It can solve the problems of no raspberry storage effect, no raspberry spraying of chemical inducers, fruit damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

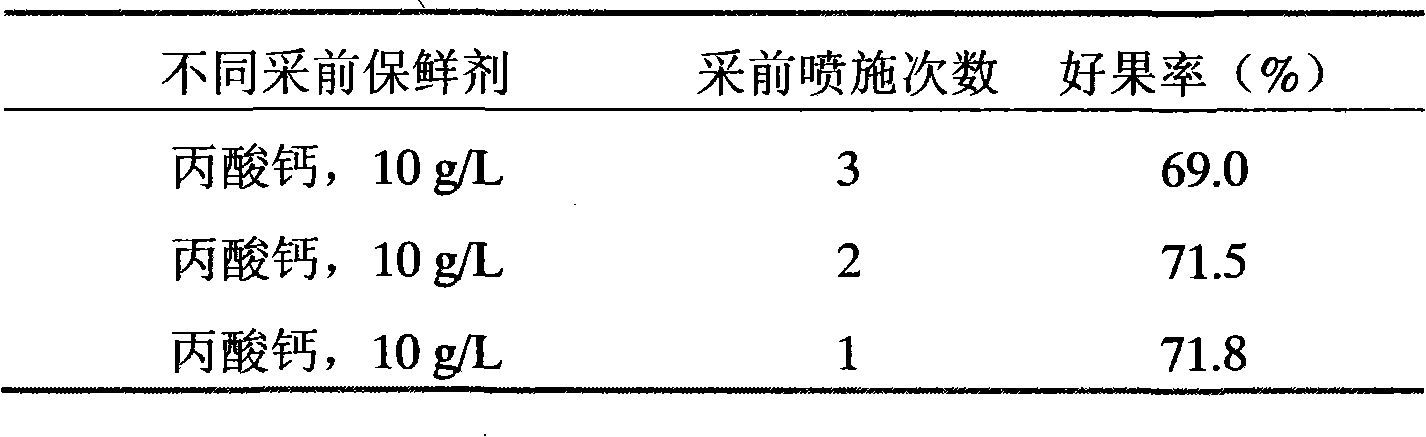

[0015] Embodiment 1: the selection of spray times before raspberry harvest

[0016] 1. Processing method

[0017] The raspberry fruit was sprayed with different times of 10g / L calcium propionate and 10g / L calcium chloride every 3 days starting from 9 days before harvesting, and 1g / L salicylic acid was sprayed with corresponding times as a control. The fruit was pre-cooled for 24 hours immediately after picking, and then stored at 1°C for 17 days to observe the good fruit rate of raspberries.

[0018] 2. Results

[0019] The results in Table 1 show that with the increase of spraying times of 10g / L calcium propionate before harvesting, the good fruit rate of raspberry fruit only decreased from 71.8% to 69.0% after storage for 17 days. In contrast, with the increase in the number of pre-harvest spraying of 10g / L calcium chloride, the good fruit rate of raspberry fruit after 17 storage dropped rapidly from 81.9% to 71.8%. With the increase of spraying times of 1g / L salicylic ac...

Embodiment 2

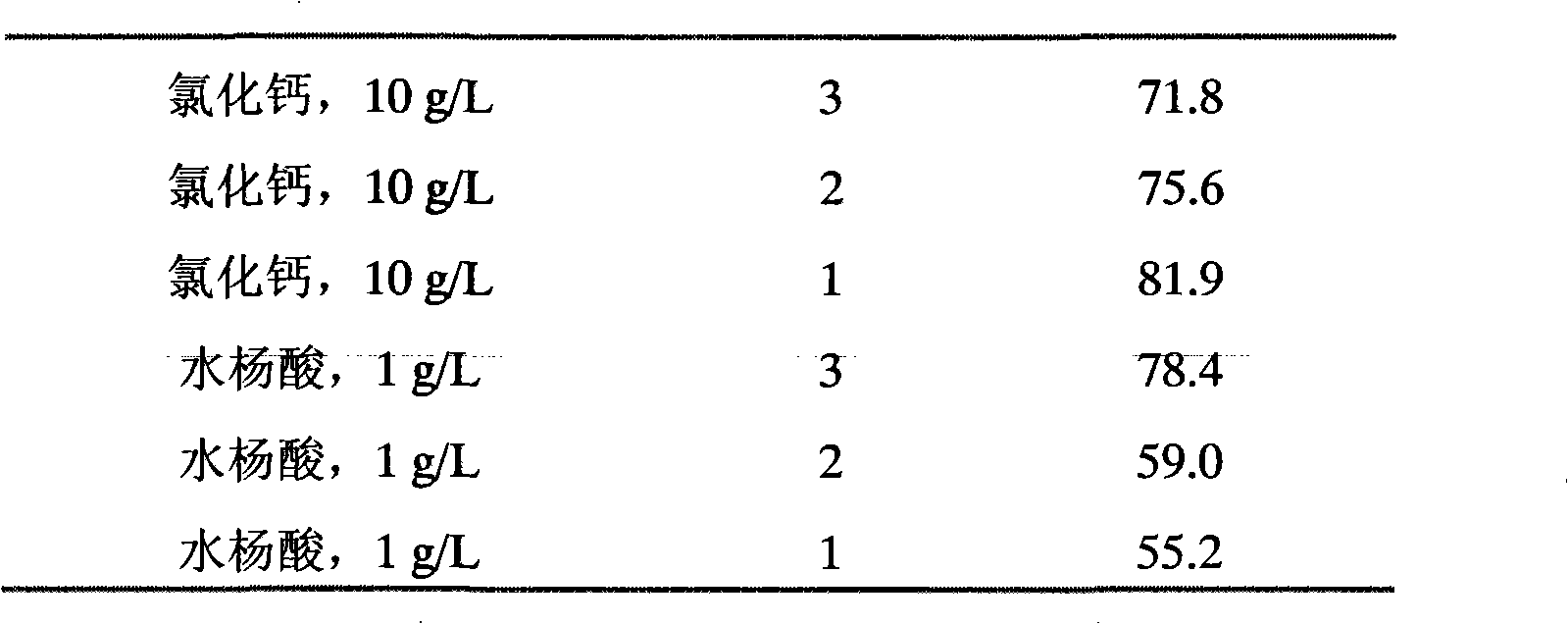

[0023] Embodiment 2: the selection of spraying concentration before raspberry harvest

[0024] 1. Processing method

[0025] Three days before harvesting, the raspberry fruit was sprayed once with different concentrations of calcium propionate and calcium chloride solutions, with distilled water sprayed as a negative control and salicylic acid sprayed as a positive control. The fruit was pre-cooled for 24 hours immediately after picking, and then stored at 1°C for 17 days to observe the good fruit rate of raspberries.

[0026] 2. Results

[0027] As can be seen from Table 1, after storage for 17 days, the good rate of raspberry fruit treated with water spraying was only 37.0%. When the concentration of salicylic acid is sprayed at 0.2-2g / L, the good fruit rate of raspberry fruit decreases with the increase of sprayed salicylic acid concentration, and the good fruit rate of raspberry fruit treated with 0.2g / L salicylic acid The highest, reaching 67.5%. In contrast, the good...

Embodiment 3

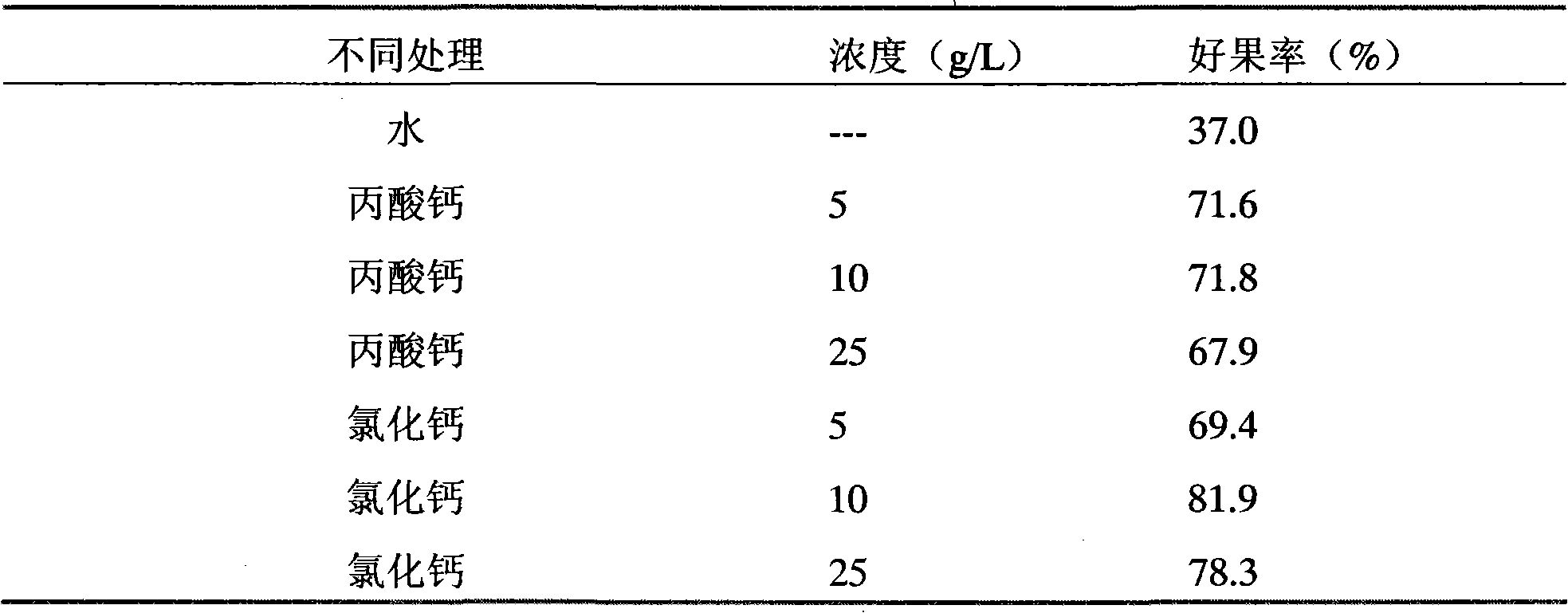

[0031] Embodiment 3: the impact of different post-harvest preservatives on raspberry fresh-keeping effect

[0032] 1. Processing method

[0033] Pick seven-ripe raspberry fruits (more red and less black on the surface), pre-cool them at 1°C for 24 hours, and then treat them with different concentrations of 1-MCP, chlorine dioxide and cinnamaldehyde for 24 hours. 1-MCP, chlorine dioxide and cinnamaldehyde were stored at 10°C for 5 days, and the good fruit rate of raspberries was counted.

[0034] 2. Results

[0035] Table 3 The fresh-keeping effect of different concentrations of preservatives on raspberries

[0036]

[0037] As can be seen from Table 2, after storage for 5 days at 10°C, the good fruit rate of the raspberry fruit of the control treatment is 61.0%; in comparison, at the concentration of 1-MCP, it is 0.5ppm and 1.0ppm, chlorine dioxide 100ppm and 200ppm and Among the six treatments of cinnamaldehyde 60ppm and 120ppm, only the good fruit rate of cinnamaldehyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com