Begin-color flame-proof antistatic polyolefin master batch

A flame retardant, antistatic, polyolefin technology, applied in the field of preparation of color masterbatches for modification of engineering plastics, can solve the problems of no natural color masterbatches, etc., achieve rich environmental perception, less added amount, and solve the resistance effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

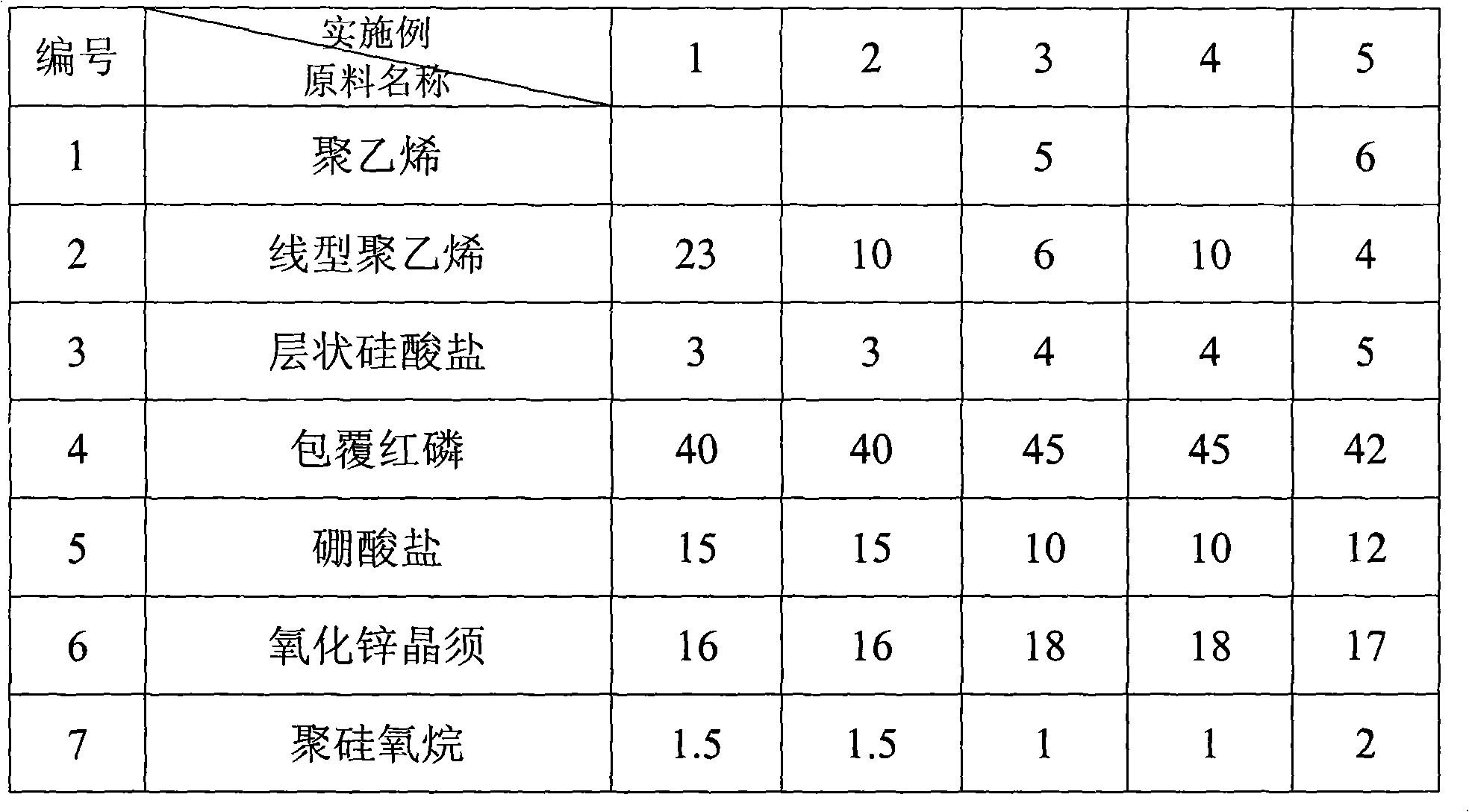

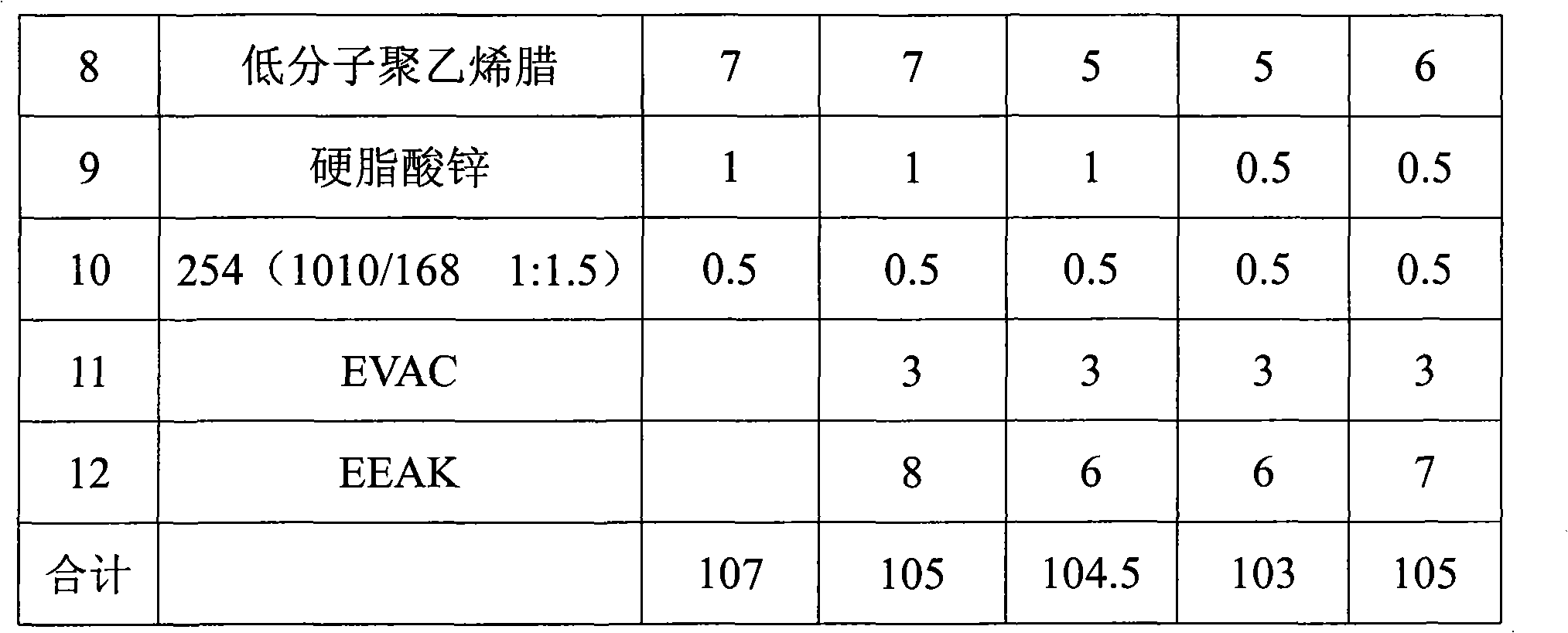

[0031] In the 5 embodiments of the present invention described in the table below, nano-layered silicate and coated red phosphorus are used as flame retardants, borates are used as char-forming agents, zinc oxide whiskers are used as antistatic agents, and organic Silicon surfactant and ethylene-vinyl acetate copolymer, ethylene-acrylic acid ester copolymer are auxiliary agents, but the examples should not be construed as limiting the scope of the present invention.

[0032]

[0033]

[0034] The process step of above-mentioned embodiment is as follows:

[0035] 1. Measure and weigh linear polyethylene, ethylene-vinyl acetate copolymer, ethylene-acrylic acid copolymer, and layered silicate according to the proportion, and then add low-molecular polyethylene wax, antioxidant Agent, zinc stearate are weighed properly, mix uniformly, add twin-screw extruder and granulate into nanocomposites for subsequent use;

[0036] 2. Put the remaining unmeasured components into the hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com