Insulation material for telephone earphone wire

A technology of insulating materials and earphone wires, applied in the direction of organic insulators, plastic/resin/wax insulators, etc., can solve the problems that insulating materials cannot be quickly decomposed, it is difficult to control the size of the tinned part, and the size of the tinned part is difficult to control, etc., to achieve Avoid surface paint film damage, small outer diameter, and ensure the effect of processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

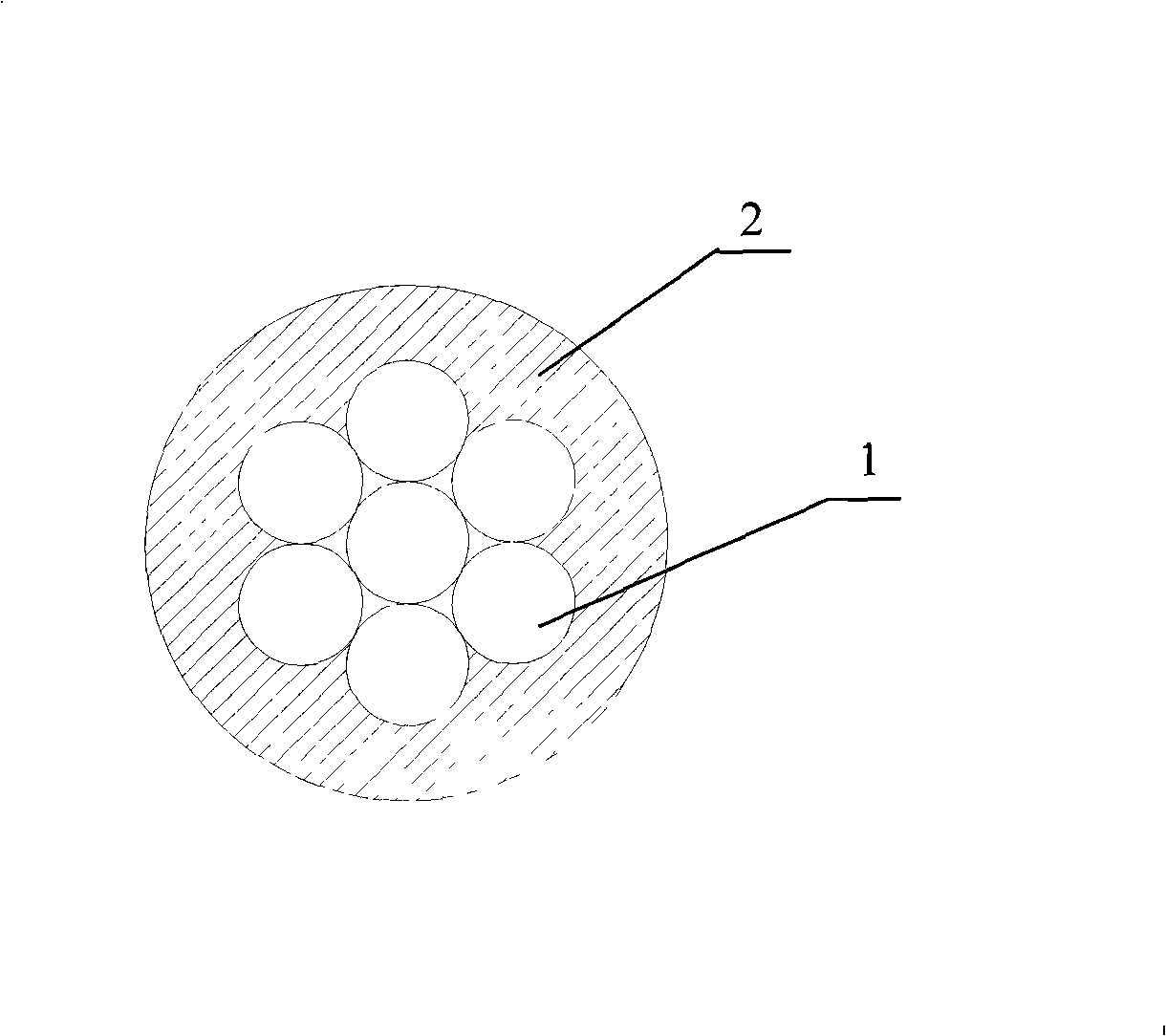

[0009] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0010] An insulating material for earphone wires, the insulating material is made by mixing thermoplastic polyester elastomer TPEE and high-density polyethylene HDPE, the mixing ratio of thermoplastic polyester elastomer TPEE and high-density polyethylene HDPE is based on the insulating material It is used to control the thickness of the insulating layer for the earphone wire. Table 1 shows a set of mixing ratios and insulating layer thickness obtained after experiments. The model of thermoplastic polyester elastomer TPEE used in the experiment is Hytrel5526. The model of high-density polyethylene HDPE is Dow 3364.

[0011] Table 1 Comparison table of the mixing ratio of thermoplastic polyester elastomer and high-density polyethylene and the insulation thickness of insulating materials

[0012] The mixing ratio

(TPEE:HDPE)

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com