Full-automatic alternating current voltage compensator

A technology of AC voltage and voltage compensation, applied in the direction of instruments, AC power input to AC power output, electrical components, etc., can solve the problem of not being able to realize voltage compensation in a timely and reliable manner, and reduce startup time and production costs. , the effect of reducing line loss and starting power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

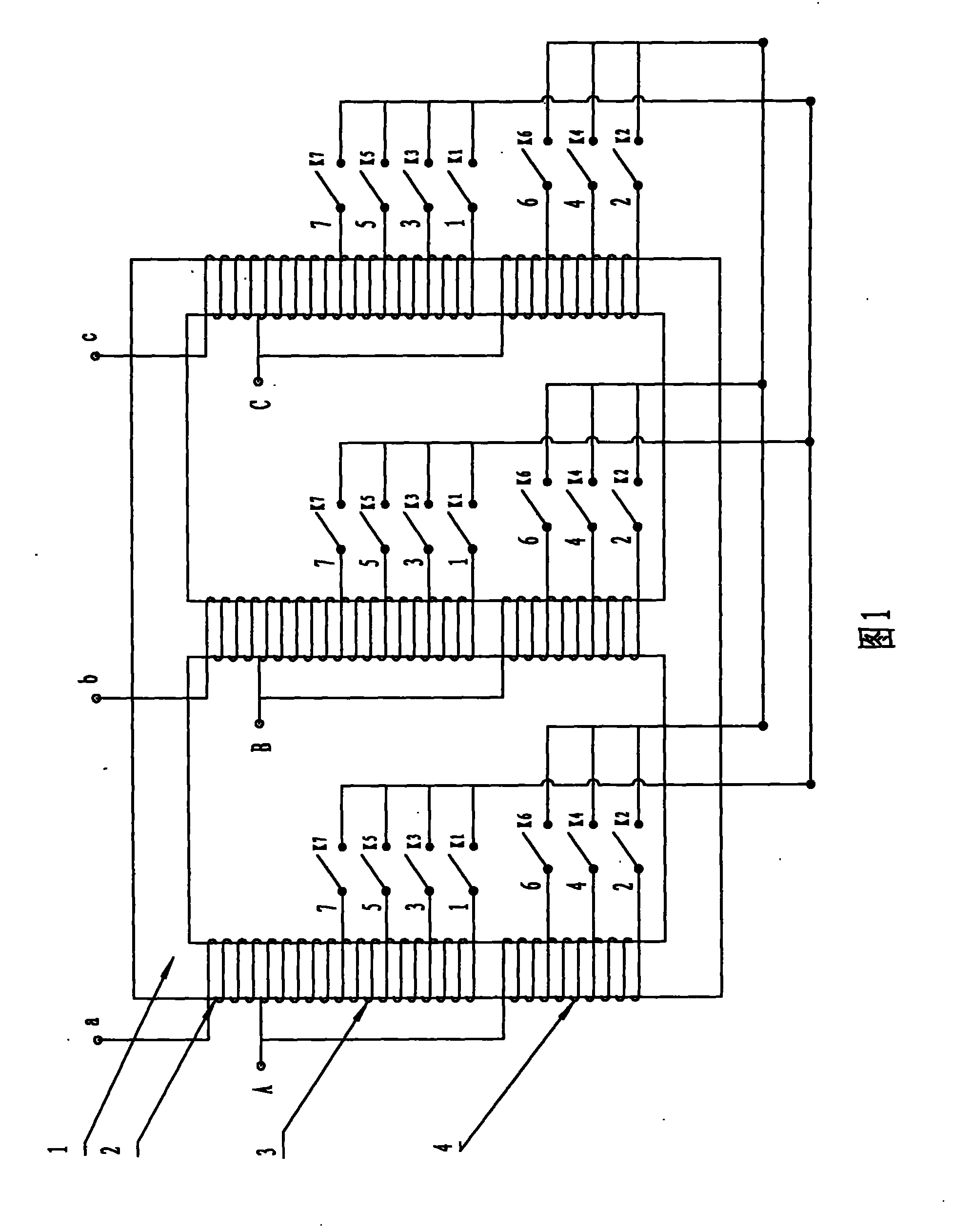

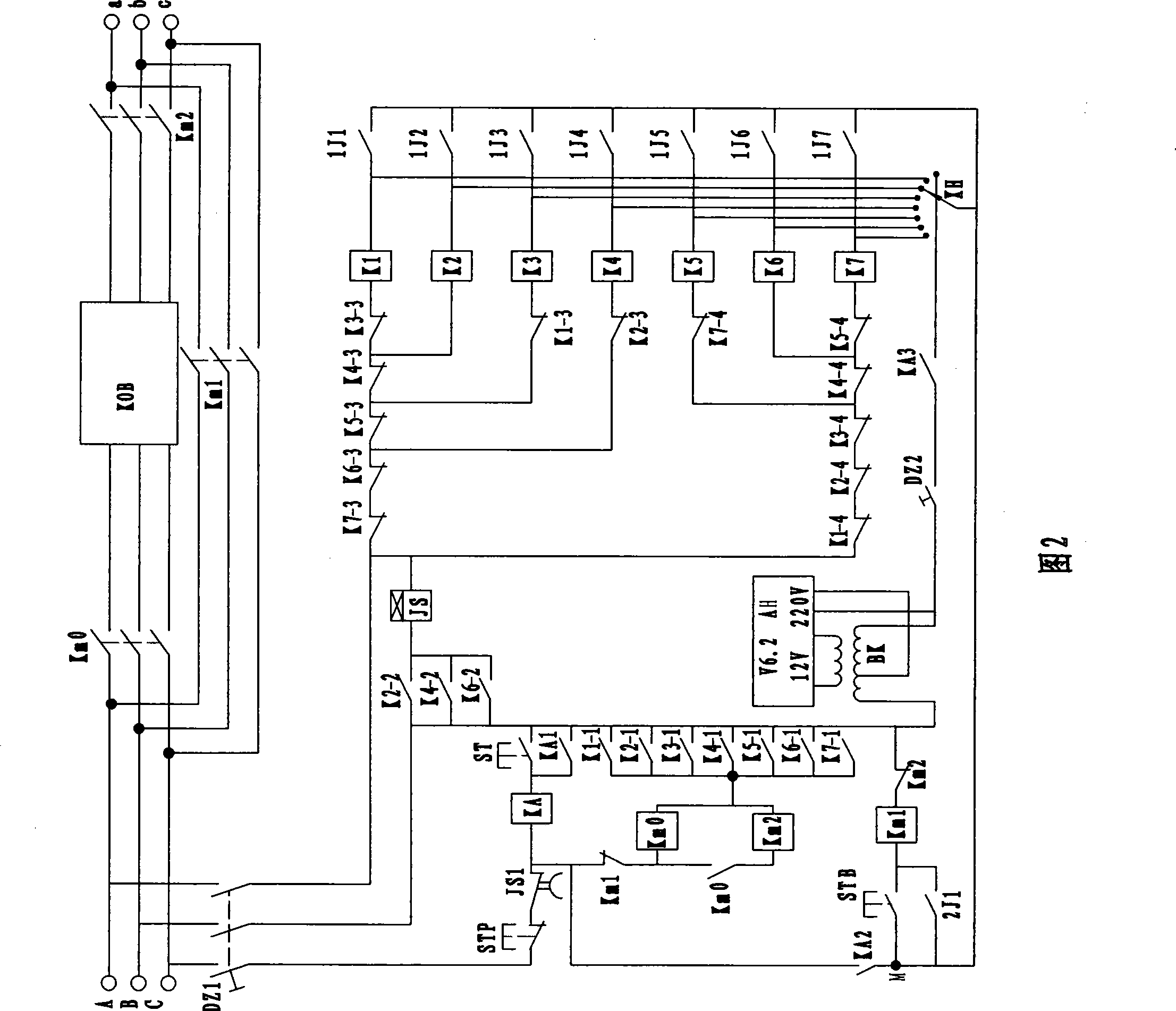

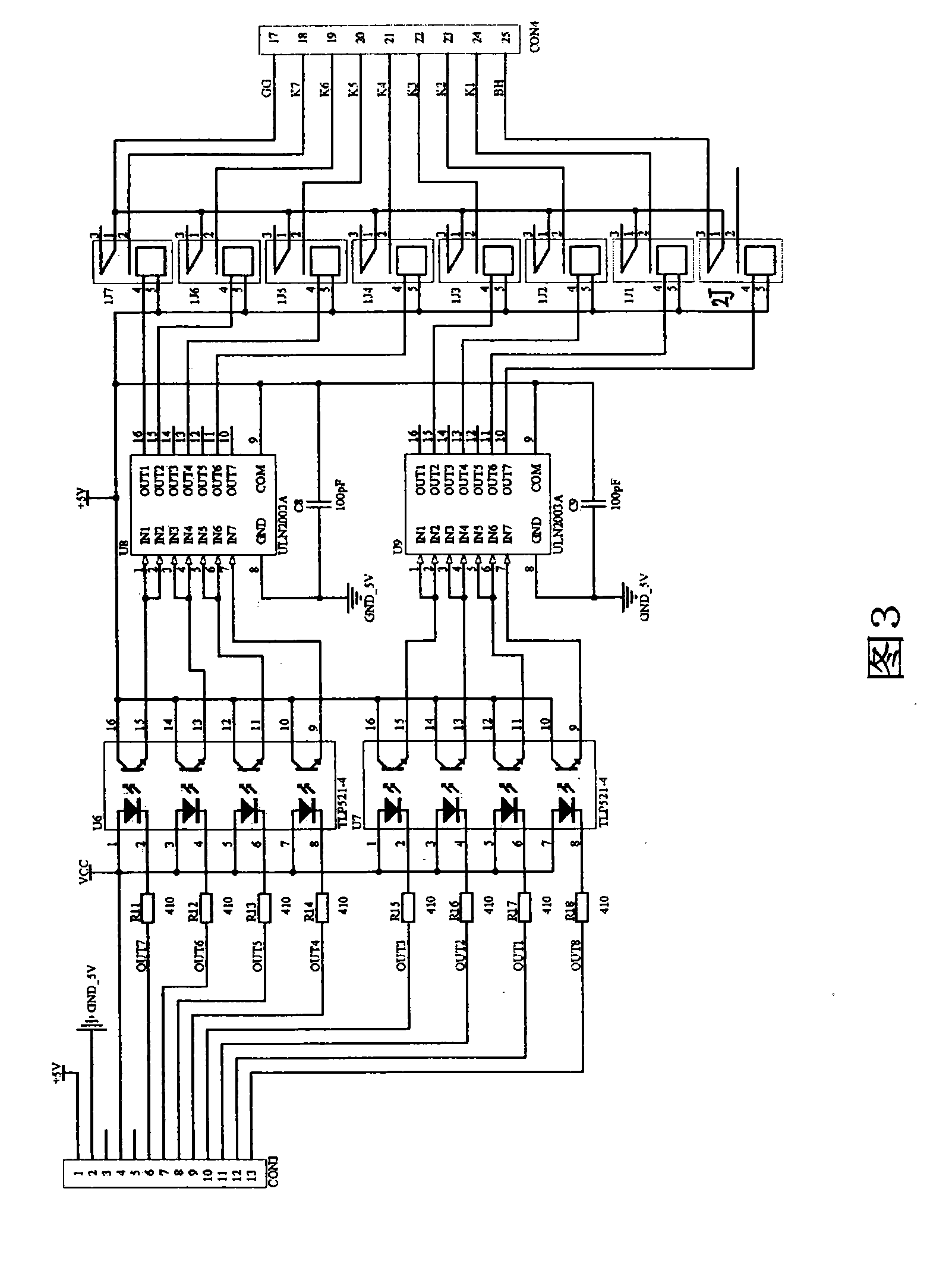

[0020] Fully automatic AC voltage compensator, including voltage compensation device KOB, three-phase AC input terminals A, B, C and three-phase AC output terminals a, b, c, and main contactors KM0, KM1, KM2 and contactors Ki’s voltage compensation device KOB control circuit, the voltage compensation device KOB control circuit is connected to the three-phase AC input terminals A, B, and C through the three-phase circuit breaker DZ1, such as figure 1As shown, the voltage compensation device includes a three-phase iron core, and corresponding three-phase coils, secondary coils, and three-phase transition coils wound on the three-phase iron cores. The star point directions of the three-phase coils and the three-phase transition coils are respectively set There are taps, the tap number h of the three-phase coil is at least two, the tap number n of the three-phase transition coil is the tap number h of the three-phase coil minus 1, and the taps of the three-phase coil and the three...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com