Cellulose acetate made from raw material hemp dissolving pulp, preparation and use thereof

A technology of cellulose acetate and a manufacturing method, which is applied to artificial filaments made of cellulose derivatives, chemical instruments, methods, instruments, etc., can solve problems such as restricting the development of cellulose acetate, and achieve a simple manufacturing method and high product quality. Good and easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

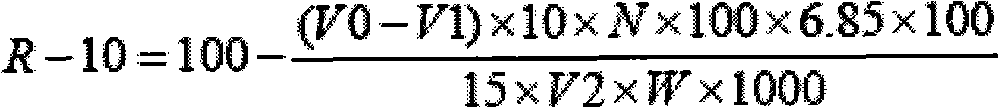

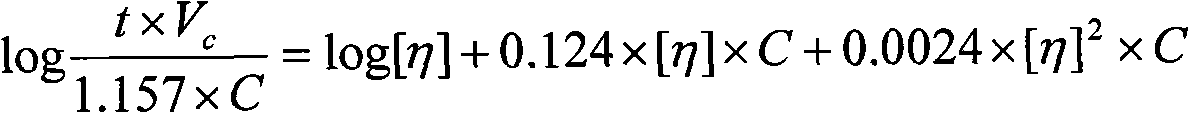

[0042] Using hemp pulp with 87% R-10 and a viscosity of 4.2dl / g as raw material, cellulose acetate was prepared through the following process:

[0043] (1) Crushing of hemp pulp: crush the finished plate-shaped hemp pulp into a fluffy appearance through a grinder.

[0044] (2) Activation: Spray acetic acid on the pulverized hemp pulp. The consumption of acetic acid is 30% of hemp pulp weight, and the temperature of activation is 25 ℃, and activation time is 70 minutes.

[0045] (3) Acetylation: Based on the weight of hemp pulp, 200% acetic acid, 15% sulfuric acid, 200% acetic anhydride and hemp pulp are added to the acetylation reactor, and the initial temperature of the reaction starts from -10°C , the rate of temperature rise was controlled at 0.6° C. / min, and the time of the acetylation reaction was 30 minutes.

[0046] (4) Hydrolysis: a magnesium acetate aqueous solution with a mass concentration of 20% was used as a hydrolyzing agent, and was added in two portions 1 hou...

Embodiment 2

[0052] Using hemp pulp with 97% R-10 and a viscosity of 8.2dl / g as raw material, cellulose acetate was prepared through the following process:

[0053] (1) Crushing of hemp pulp: the finished flocculent hemp pulp is crushed into a velvet appearance through a grinder.

[0054] (2) Activation: Spray acetic acid on the pulverized hemp pulp. The consumption of acetic acid is 35% of hemp pulp weight, and the temperature of activation is 30 ℃, and activation time is 40 minutes.

[0055] (3) acetylation: take the hemp pulp weight as a basis, 300% acetic acid, 10% sulfuric acid, 220% acetic anhydride and hemp pulp are added in the acetic reaction reactor, and the initial temperature of reaction begins from 4 ℃, The rate of temperature rise was controlled at 0.8° C. / min, and the time of the acetylation reaction was 49 minutes.

[0056] (4) Hydrolysis: adopt the magnesium acetate aqueous solution that mass concentration is 20% as hydrolyzing agent, add in three times in 1 hour, 2.5 ho...

Embodiment 3

[0062] Using hemp pulp with 62% R-10 and a viscosity of 10dl / g as raw material, cellulose acetate was prepared through the following process:

[0063] (1) Crushing of hemp pulp: crush the finished plate-shaped hemp pulp into a fluffy appearance through a grinder.

[0064] (2) Activation: Spray acetic acid on the pulverized hemp pulp. The consumption of acetic acid is 200% of the hemp pulp weight, the temperature of activation is 40 ℃, and the activation time is 300 minutes.

[0065] (3) Acetylation: taking the hemp pulp weight as a basis, 800% acetic acid, 20% sulfuric acid, 400% acetic anhydride and hemp pulp are added in the esterification reactor, and the initial temperature of the reaction starts from 20°C. The rate of temperature rise was controlled at 0.5° C. / min, and the time of the acetylation reaction was 40 minutes.

[0066] (4) Hydrolysis: a magnesium acetate aqueous solution with a mass concentration of 10% was used as a hydrolyzing agent, and was added twice in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com