Paper honeycomb core ultrathin natural stone composite board

A technology of honeycomb core and composite board, which is applied in the direction of covering/lining, layered products, chemical instruments and methods, etc., which can solve the problems of high value, large relationship between stone texture quality and value, and small quantity of stone, so as to achieve wide application , low cost, and the effect of heat preservation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

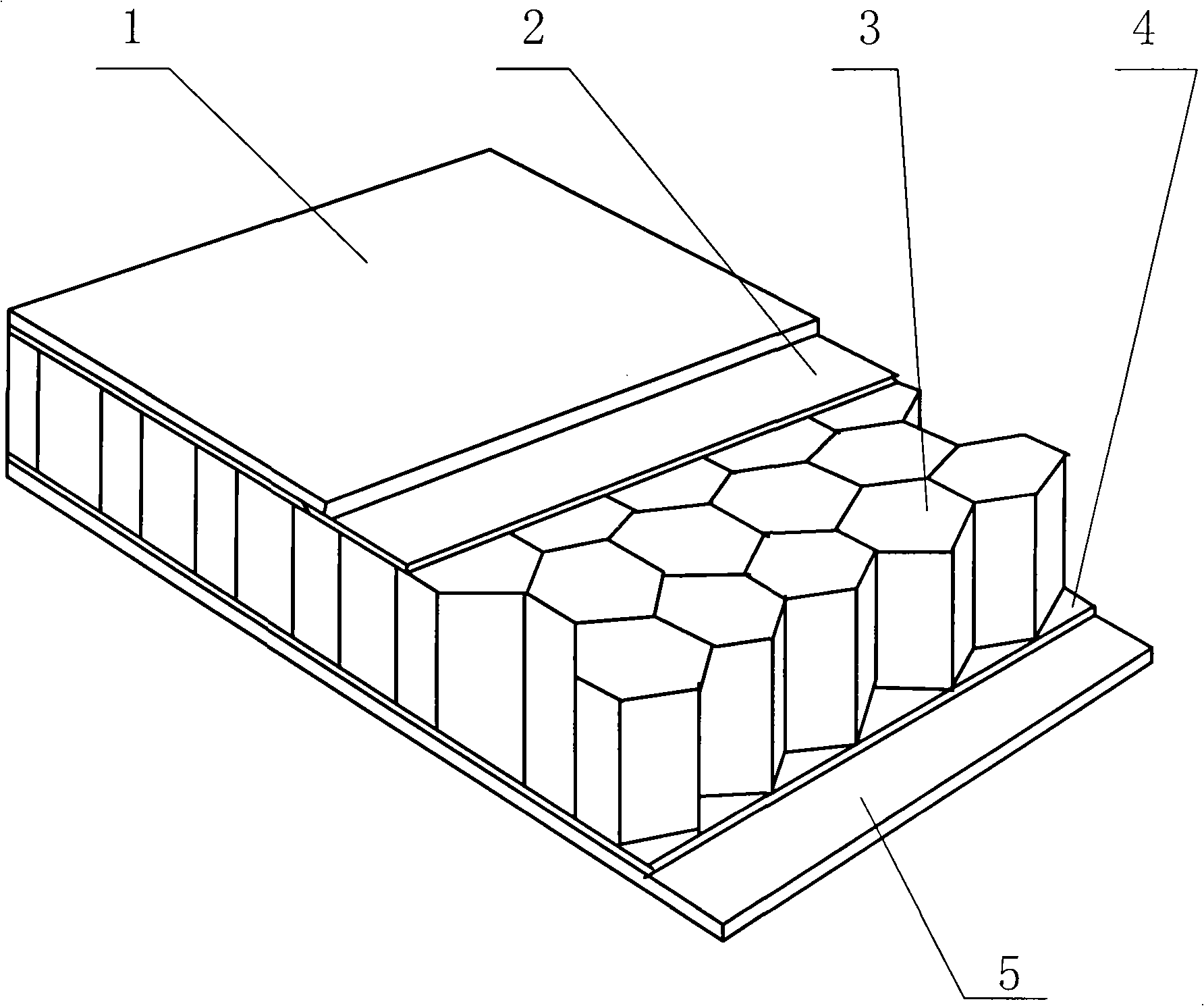

[0012] figure 1 Among them, the front of the ultra-thin natural stone slab (1) is polished and polished, and the back is alternately coated with multiple layers of resin and glass fiber to form a glass fiber resin layer (2), which is then laminated with ordinary paper to make a honeycomb shape, and then resin-impregnated. After increasing the strength and moisture-proof effect of the paper honeycomb core (3), then the side of the glass fiber bottom plate (5) coated with the resin adhesive layer (4) is laminated with the paper honeycomb core (3) and pressed tightly. After edge treatment, it becomes an ultra-thin natural stone composite board with paper honeycomb core.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com