Air mass flow sensor of silicone base thin-film structure

An air mass flow, silicon-based thin film technology, used in indirect mass flow meters, mass flow measurement devices, measurement flow/mass flow, etc., can solve problems such as inability to reduce power loss, limited measurement range, difficult temperature sensitivity coefficients, etc. , to reduce power loss, expand measurement range, and improve heat dissipation coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

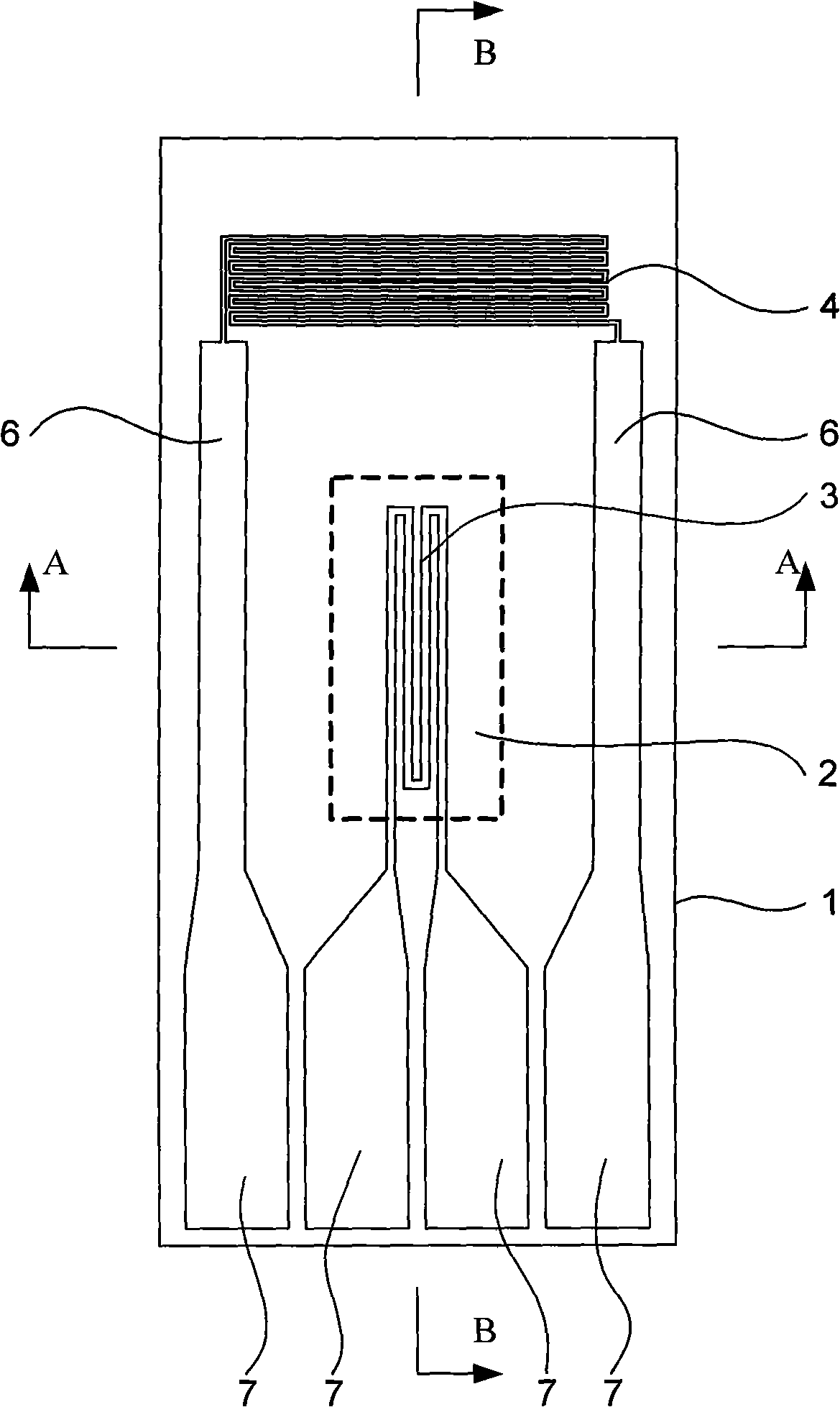

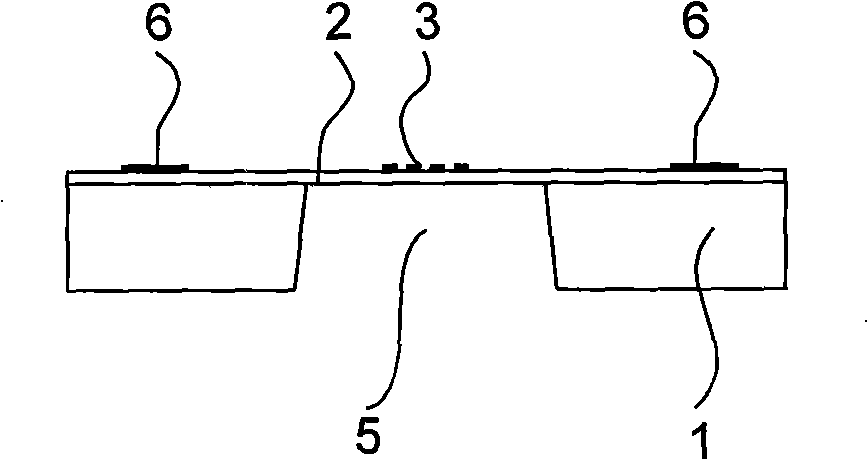

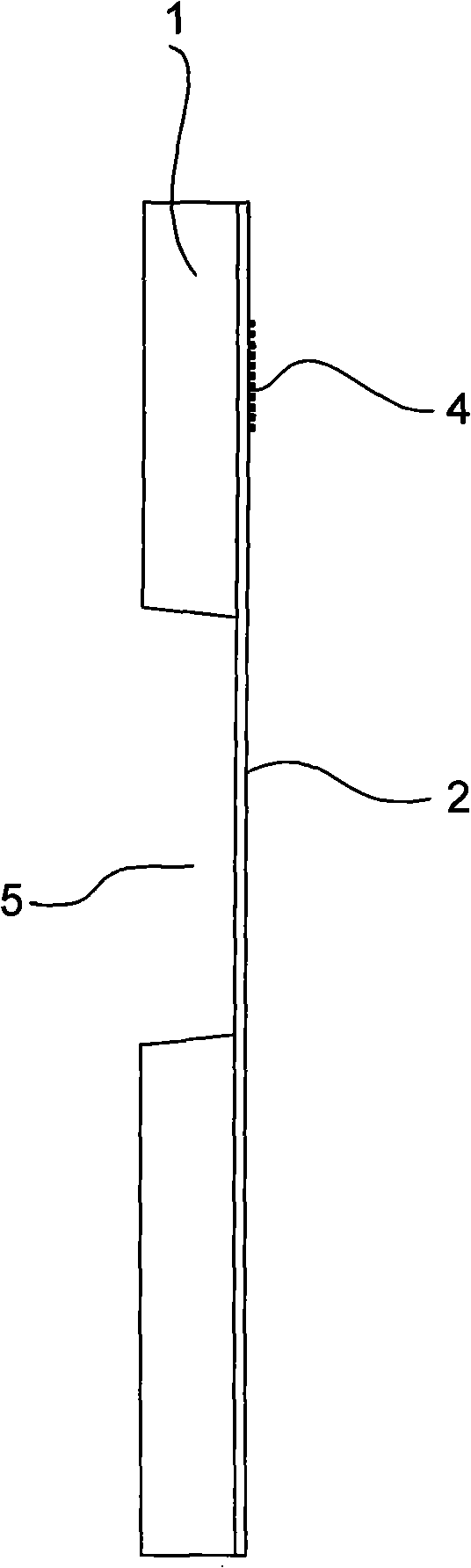

[0012] Embodiments of the present invention will be described below with reference to the drawings.

[0013] Such as figure 1 , figure 2 , image 3 As shown, the air mass flow sensor involved in the embodiment of the present invention adopts a silicon-based film sensitive structure based on MEMS technology. The sensitive structure is composed of a base material 1 , an insulating film 2 , a heating resistor 3 , a temperature measuring resistor 4 , a heat insulating cavity 5 , a temperature measuring resistor wiring 6 , and a bonding pad 7 . The base material 1 adopts single crystal silicon material. A layer of insulating film 2 is covered thereon. In the middle area of the entire sensitive structure, an insulating cavity 5 is formed by an etching process, so that only a layer of insulating film 2 with a thickness of only a few microns remains in this area. Then, the heating resistor 3 is formed on the insulating film 2 by processes such as deposition, photolithography, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com