Analog system for coal seam mash gas dynamic action

A technology of coal seam gas and simulation system, which is applied in educational tools, teaching models, instruments, etc., can solve the problems that there are not many simulation experiments of coal and gas dynamic action, and there are few research results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

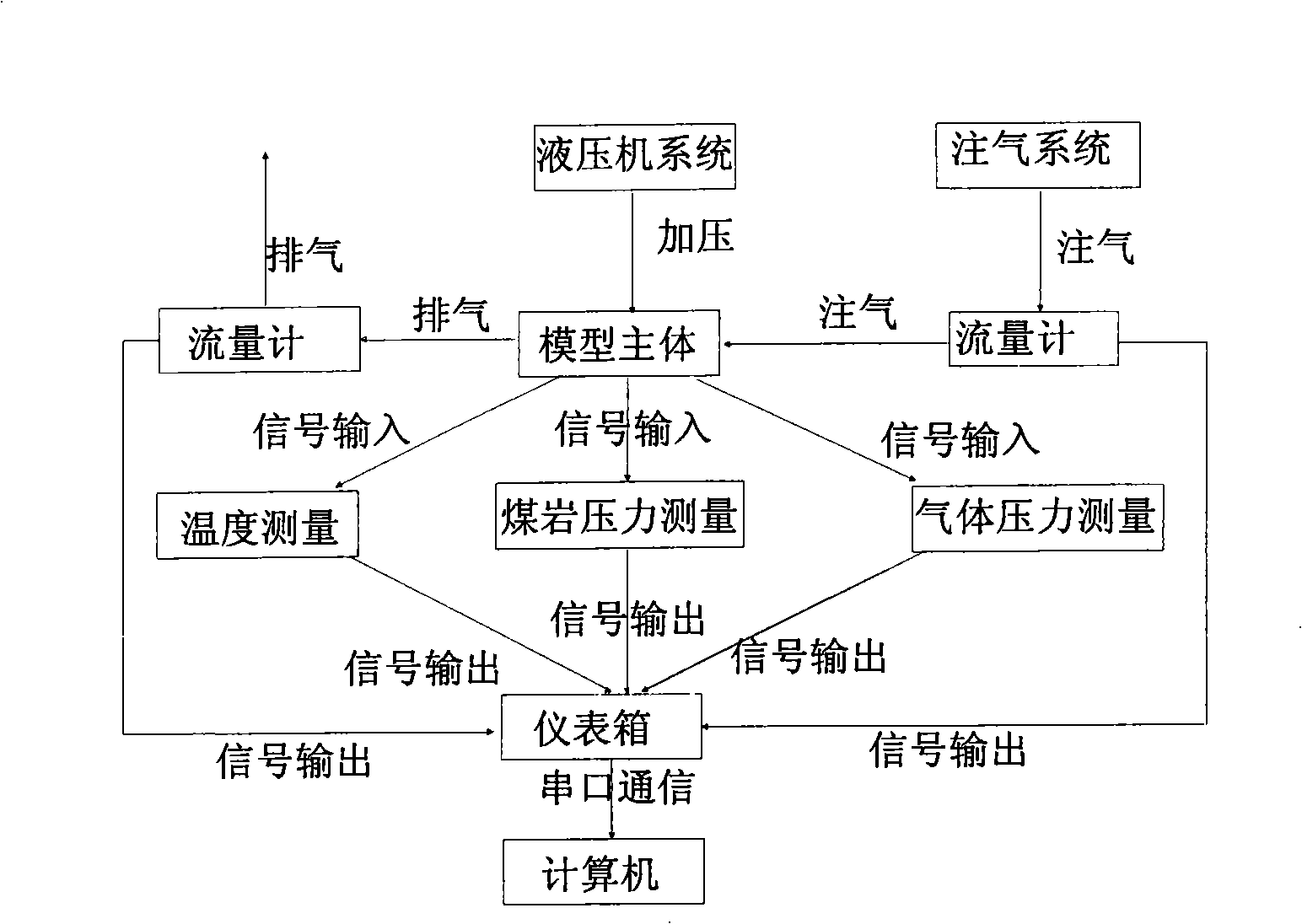

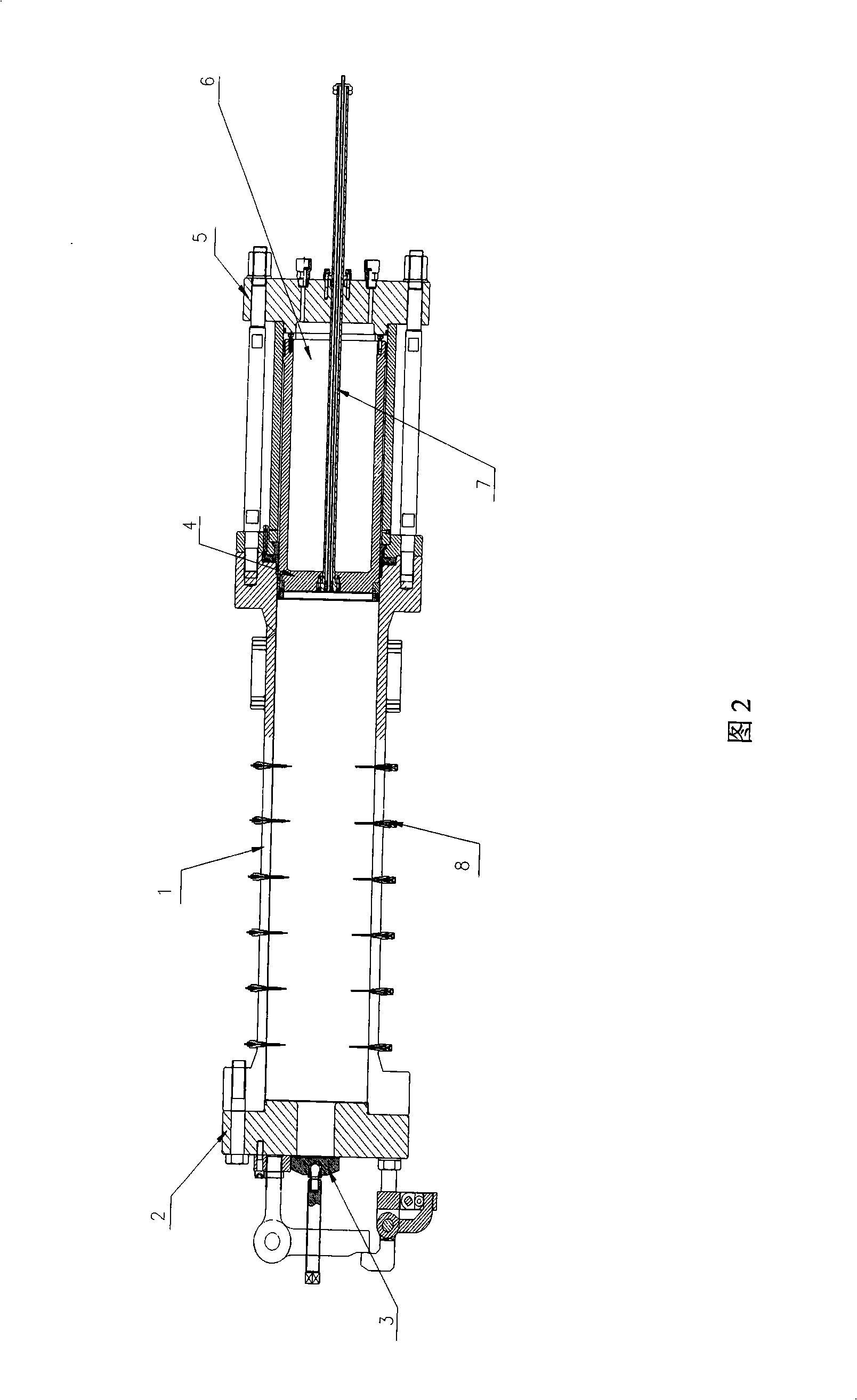

[0018] Coal seam gas dynamic action simulation system includes gas injection system, sample loading system, compaction system and information collection system. The sample loading system includes a cylinder body 1, which is made of corrosion-resistant and high-pressure-resistant materials. In order to reduce the processing difficulty and improve the manufacturability, the cylinder body 1 is designed to be divided into two sections, and the inner wall is roughened to prevent cross-flow. Install the discharge end cover 2, there is a discharge port on the discharge end cover 2, the quick-opening air relief valve 3 is installed on the discharge end cover, and the other section is equipped with a hydraulic plunger 4, a hydraulic cylinder end cover 5, a hydraulic plunger 4, a hydraulic There is a sealing mechanism between the cylinder end covers 5, and a sealing adjustment mechanism is arranged outside the hydraulic cylinder end cover 5, so that the seal can be guaranteed by pressing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com