Method for production of martensitic stainless steel pipe

A technology of stainless steel pipes and manufacturing methods, applied in the direction of manufacturing tools, metal rolling, furnace types, etc., which can solve undisclosed problems and achieve the effect of suppressing flashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

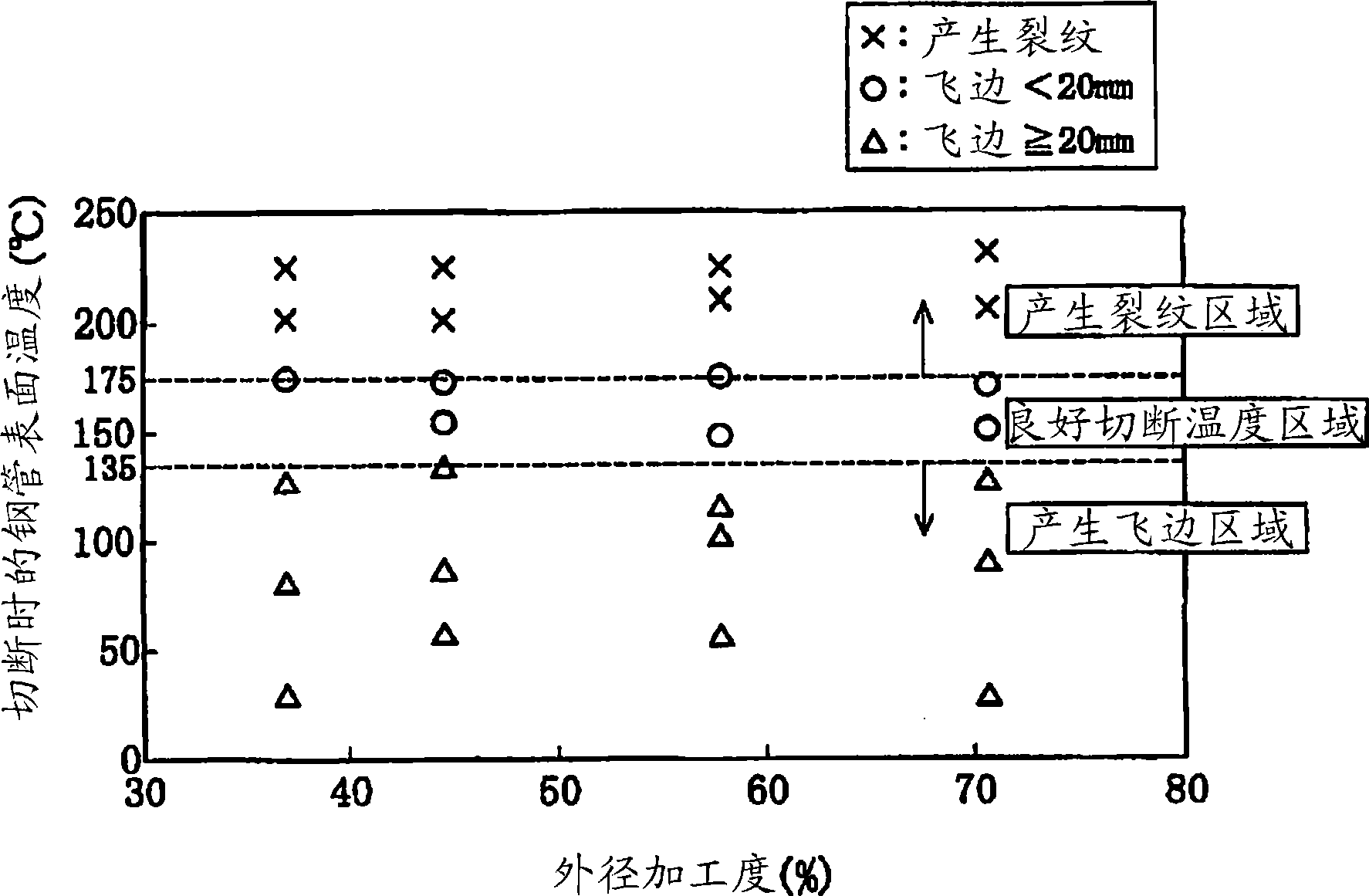

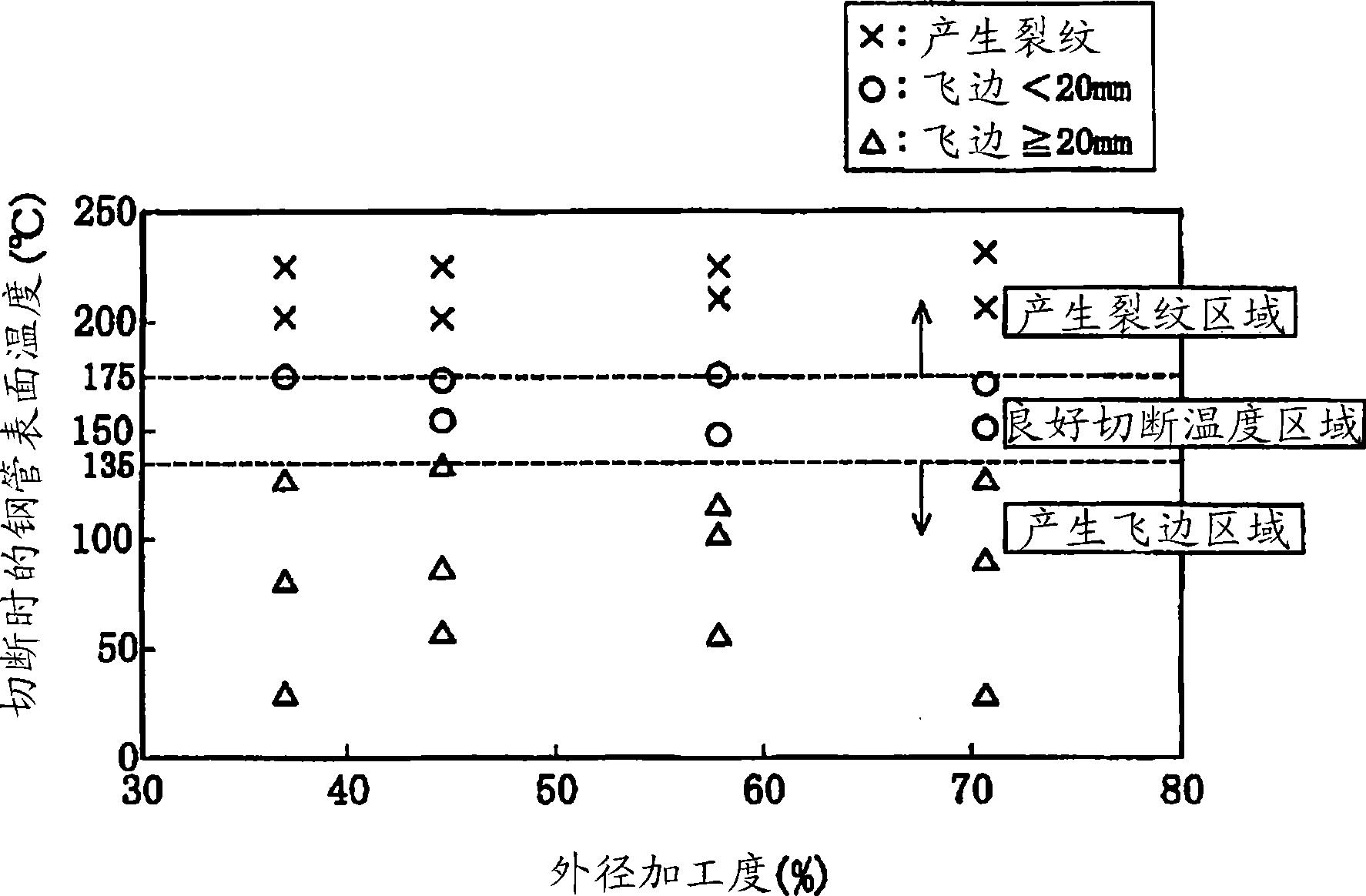

[0041] Steel slabs having the chemical composition shown in Table 1 were smelted and hot-processed with a Mannesmann mandrel mill to produce seamless tubes with various outer diameters (that is, various degrees of outer diameter processing) and a length of 10 m. Seam steel pipe. The tube was heated for an additional 16 minutes in a furnace at a furnace temperature of 1050°C and then cooled in air.

[0042] At various surface temperatures, the pipe ends were cut with a saw having the cutters shown in Table 2 under the conditions shown in Table 3. After cutting, the occurrence of cracks and burrs were evaluated by the following evaluation methods. In addition, the surface temperature of the tube was measured with a radiation thermometer.

[0043] Crack Evaluation Method

[0044] Pickling is carried out after removing scale on the inner and outer surfaces of the tube with a shot blasting machine, and the presence or absence of cracks is evaluated by visually inspecting the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com