Rotary extrusion forming method of non-circular cross-section parts and equipment thereof

A non-circular cross-section, spinning forming technology, applied in the field of plastic processing, can solve the problems of reducing the mechanical properties of materials, affecting the normal use of parts, prolonging the processing cycle, etc., and achieve the effect of simple structure, improved production efficiency and short processing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

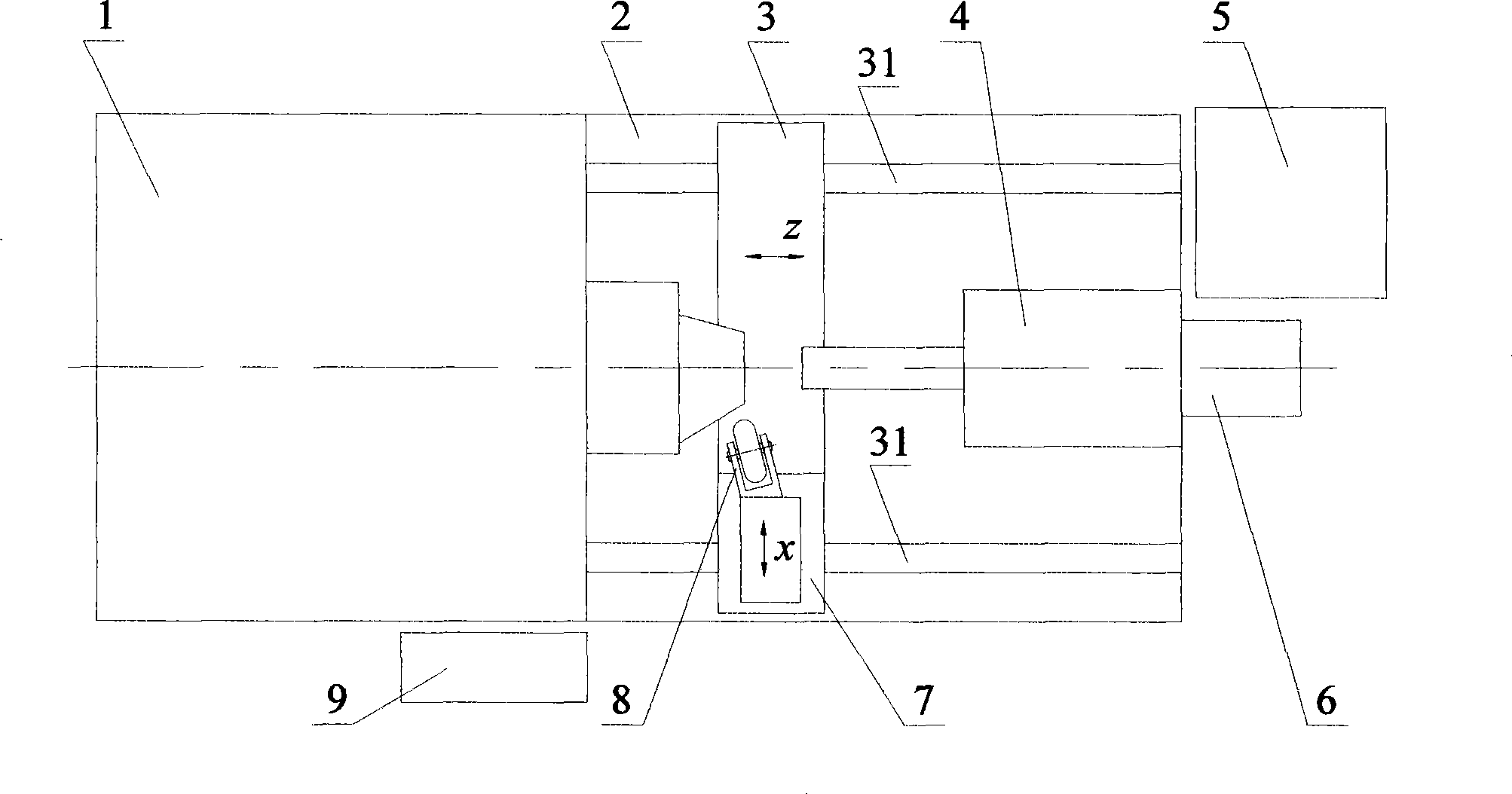

[0032] A spinning forming method of a non-circular section part of the present invention comprises the following steps:

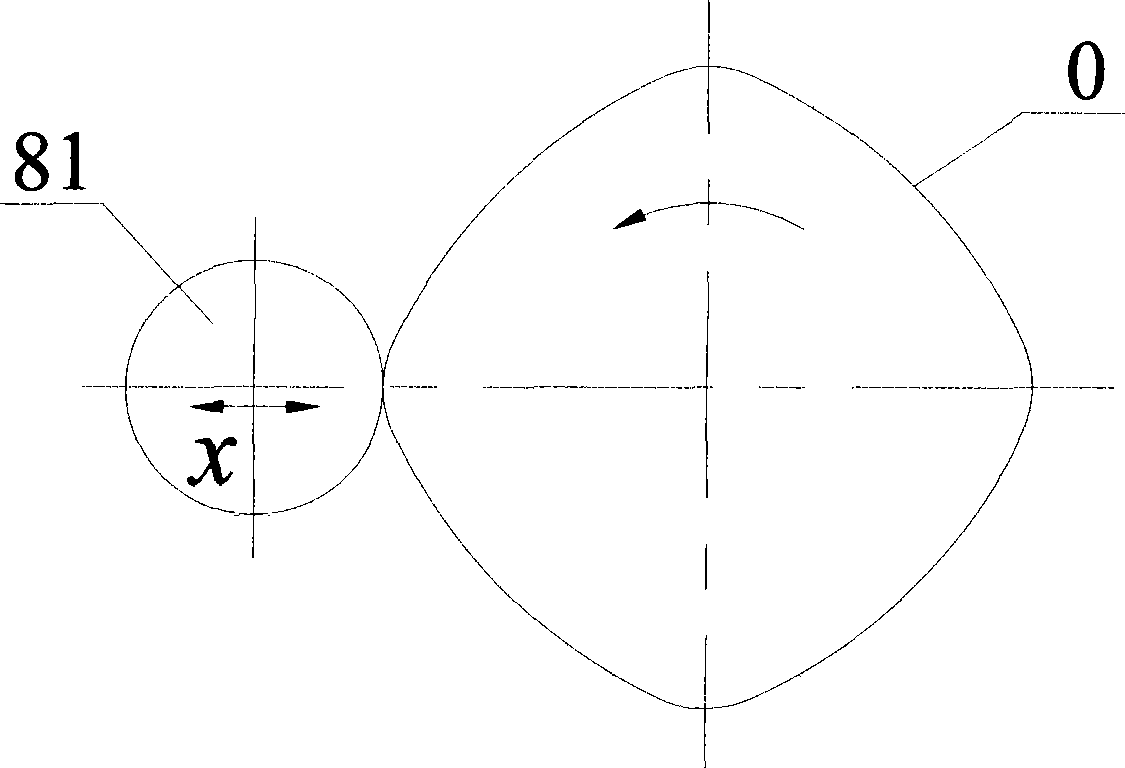

[0033] (1) if figure 1 As shown, according to the shape and size of the non-circular cross-section part O, set the feed trajectory of the rotary wheel (including the feed amount, the number of feeds of the rotary wheel when the main shaft rotates one revolution, etc.) and the feed speed on the console;

[0034] (2) To install the workpiece, that is, to clamp the workpiece on the shaft head of the main shaft first, and then drive the tail top device to clamp it by the hydraulic station, then start the servo motor feeding device, adjust the longitudinal moving platform so that the rotary wheel reaches the position close to the workpiece specified location;

[0035] (3) Start the spindle to rotate, and the spindle rotates to drive the workpiece to rotate;

[0036] (4) Simultaneously start the linear motor feed device to control the horizontal movement of the...

Embodiment 2

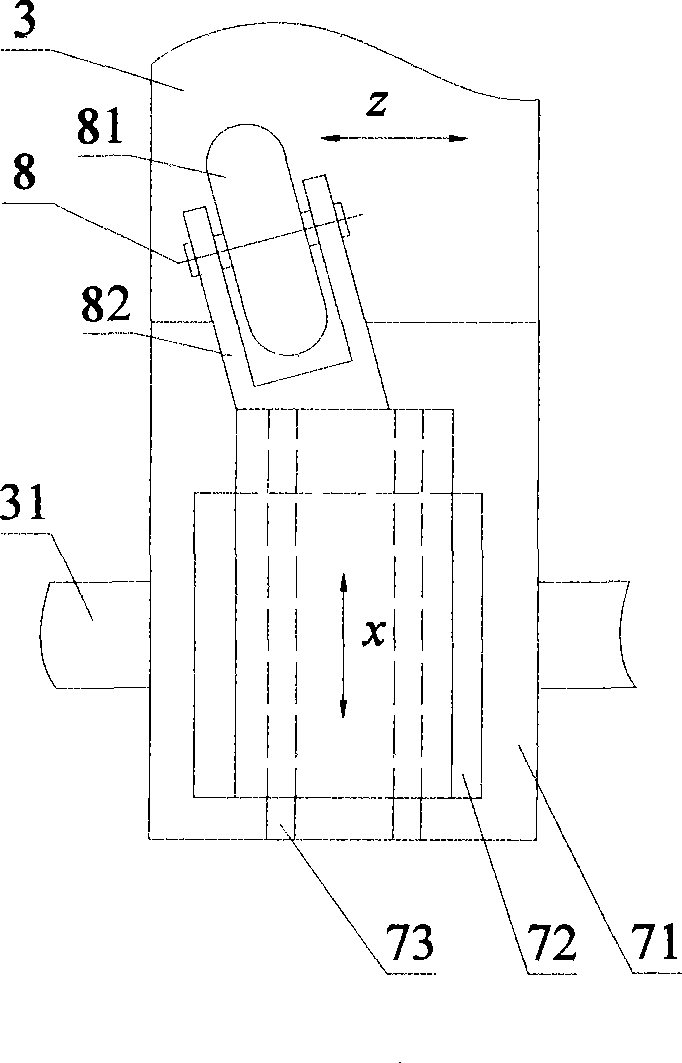

[0042] The spinning forming method of the non-circular cross-section parts of this embodiment is the same as that of Embodiment 1, and the working principle of the spinning forming equipment of the non-circular cross-section parts is also the same as that of Embodiment 1. Another method of the spinning forming equipment of the non-circular cross-section parts is a structure such as Figure 4 As shown, the difference from Embodiment 1 lies in the structure of the rotary wheel device 8 , and the addition of an inclined plane booster mechanism 10 between the linear motor feeding device 7 and the rotary wheel device 8 .

[0043] Such as Figure 5 As shown, between the linear motor feeding device 7 and the rotary wheel device 8, an inclined plane booster mechanism 10 is added, wherein the inclined plane booster mechanism 10 includes an inclined plane propulsion block 101 and a roller 102; the rotary wheel device 8 includes a rotary wheel seat 83, Horizontal linear guide rail 84, r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com