Electron-bombardment welding technique

A technology of vacuum electron beam welding and electron beam welding, which is applied in electron beam welding equipment, manufacturing tools, welding equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

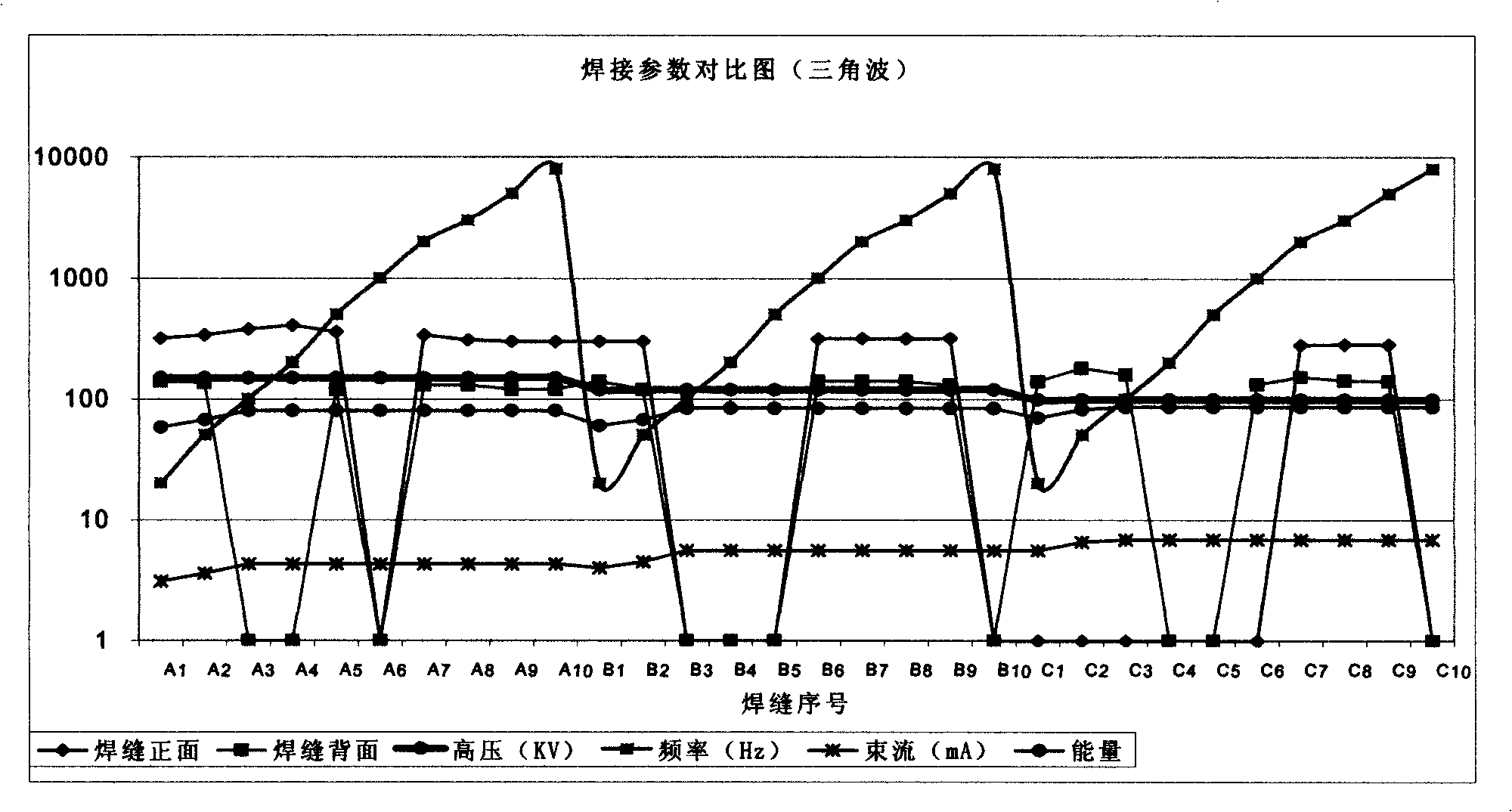

Image

Examples

Embodiment 1

[0046] A vacuum electron beam welding process, characterized in that: the vacuum electron beam welding process includes a linear zoom welding control technology and welding parameters that can effectively eliminate black lines generated during electron beam welding of the combination of GH4169 and K4169 materials, wherein The linear variable focal length welding control technology is realized on the welding machine whose electrical parameters and mechanical parameters can be controlled by CNC. For the welding with sudden change in section, it is necessary to calculate the mechanical position parameters and control the current and aggregate current parameters, that is, at the sudden change in section, welding The current and focusing current change accordingly to realize single-sided welding and double-sided molding; it can effectively eliminate the welding parameters of black lines generated when GH4169 and K4169 are combined by electron beam welding. The welding parameters sele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com