Preparation method of rectangular pyramid metal lattice material

A metal lattice and quadrangular pyramid technology is applied in the field of preparation of a sandwich structure of quadrangular pyramid metal lattice materials, and can solve the problems of different mechanical properties of metal powders, low strength of quadrangular pyramid lattice materials, and bonding strength between core and panel. It can achieve the effect of high degree of automation, short production cycle, high dimensional accuracy and position accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The preparation method of the present invention will be described in detail below in conjunction with the accompanying drawings.

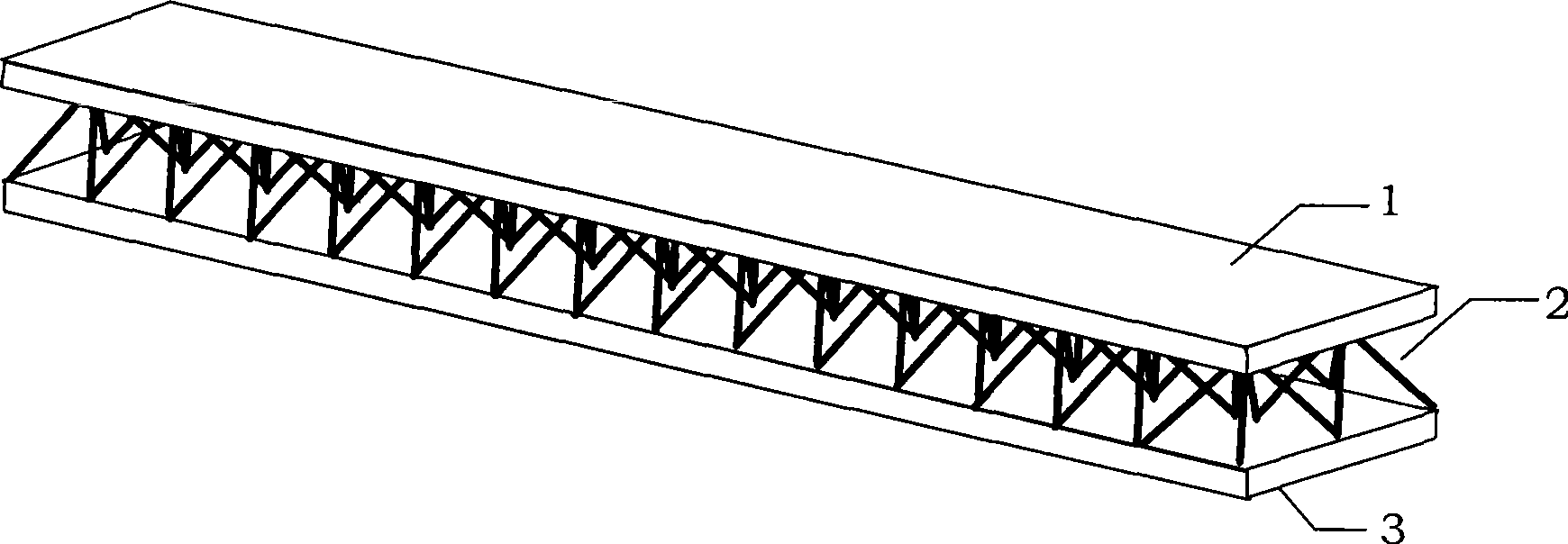

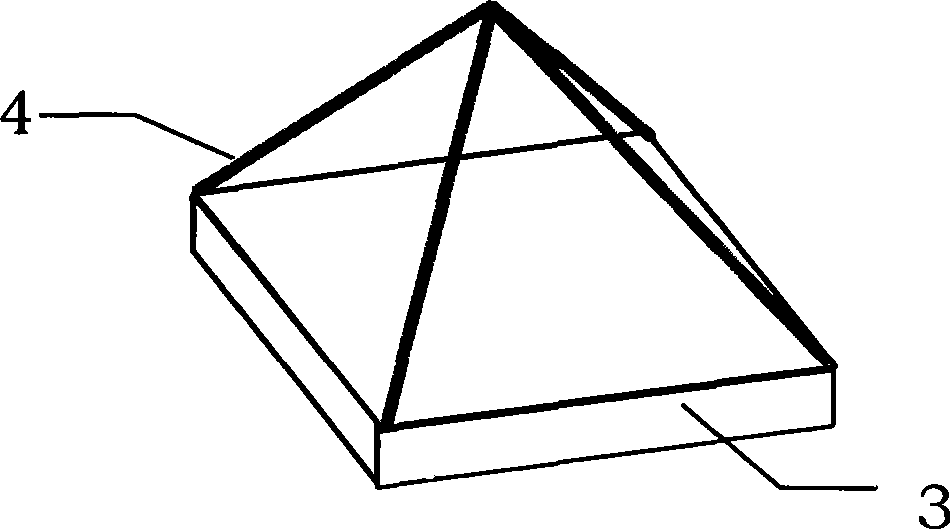

[0020] figure 1 It is a schematic diagram of a sandwich beam made of quadrangular pyramid lattice material. The sandwich beam is composed of an upper panel 1, a lower panel 3 and a sandwich core 2, wherein the sandwich core 2 is composed of many quadrangular pyramid cells, such as figure 2 As shown, each quadrangular pyramid cell contains four identical rod elements 4 , and the bottom of the quadrangular pyramid cell is the lower panel 3 .

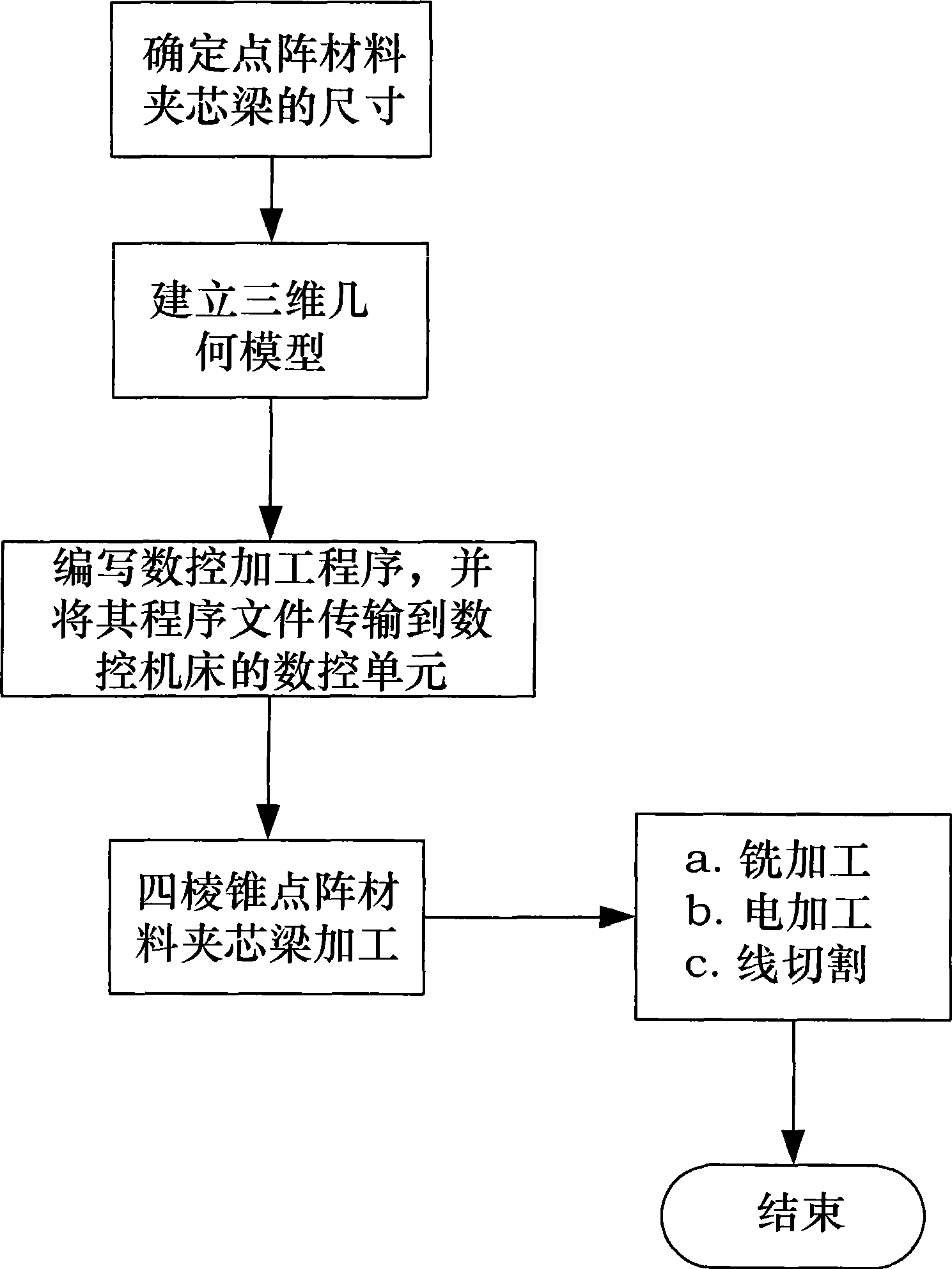

[0021] The most common quadrangular pyramid lattice material is 304# steel and 6061 aluminum alloy, take 304# steel quadrangular pyramid lattice material sandwich beam as example below, illustrate the preparation process utilizing the preparation method of the present invention, concrete implementation process is as follows image 3 The flow chart given is as follows:

[0022] (1) Determine the geomet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com