Double layer chromium electroplating processing process for conveying cylinder

A processing technology and conveying cylinder technology, which is applied in the field of concrete conveying cylinder processing technology, can solve the problems of poor bonding force between coating and cylinder body metal, shortening the service life of conveying cylinder, and high hardness of chromium layer, so as to avoid the peeling of chromium layer and prolong the Corrosion battery time, corrosion resistance and bonding force improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

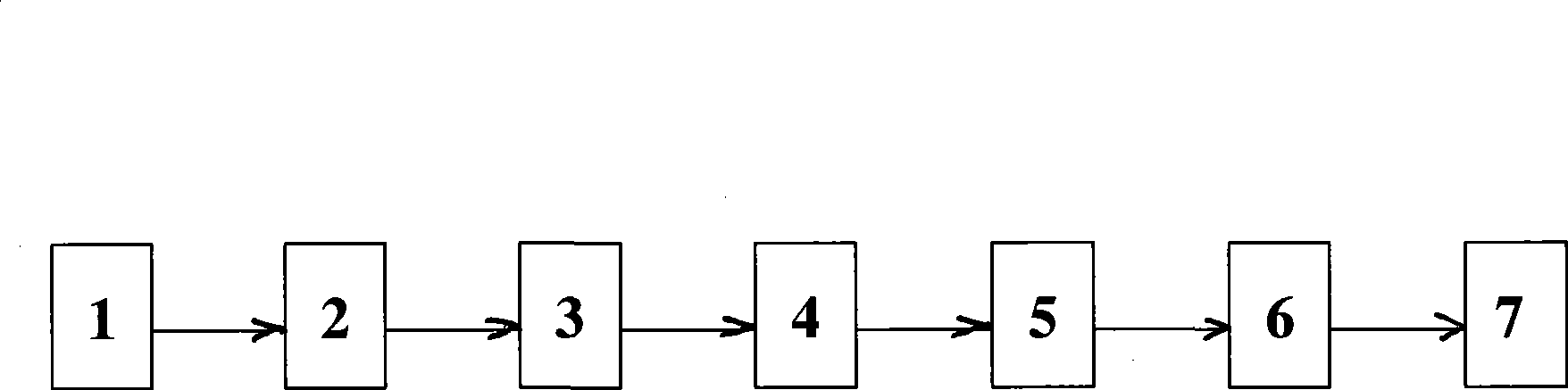

[0021] As shown in the accompanying drawings, the production process of the present invention is carried out according to the following steps.

[0022] a. To prepare the electroplating solution, use 220-250 g / L CrO 3 solution and 2.5-3.1 g / L of H 2 SO 4 Solution by CrO 3 with H 2 SO 4 The weight ratio is 100:1.15 and mixed evenly to form electroplating solution 1;

[0023] b. Pour the prepared electroplating solution 1 into the electroplating tank;

[0024] c. Increase the temperature of the electroplating solution 1 in the electroplating tank to 68°C to form the pre-plating plating solution 2;

[0025] d. Put the clean delivery cylinder into the electroplating solution of the electroplating tank and preheat it to the temperature of the electroplating solution to form the delivery cylinder 3 to be plated;

[0026] e. Pass 15A / dm to the electroplating tank 2 Reverse power supply for back-etching and etching, and further remove the sundries on the surface of the conveyin...

Embodiment 2

[0032] This embodiment is basically the same as Embodiment 1, the difference is that in technical step a, CrO 3 with H 2 SO 4 The weight ratio is 100:1.25, the temperature of the electroplating solution in technical step c is increased to 72°C, and the reverse power supply current in technical step e is 25A / dm 2 , the forward current in technical step f is 25A / dm 2 , the temperature of the plating solution in technical step g drops to 57°C, and the current in technical step h increases to 45A / dm 2 .

Embodiment 3

[0034] This embodiment is basically the same as Embodiment 1, except that what adopts in technical step a is CrO 3 with H 2 SO 4 The weight ratio is 100:1.2, the temperature of the electroplating solution in technical step c is increased to 70°C, and the reverse power supply current in technical step e is 20A / dm 2 , the forward current in technical step f is 20A / dm 2 , the temperature of the plating solution in technical step g drops to 55°C, and the current in technical step h increases to 40A / dm 2 .

[0035] The above three embodiments can draw the following conclusions: the use of electroplating solutions of different components, temperature, and current to electroplate the delivery cylinder with milky white chromium and hard chrome can make the delivery cylinder plated with double-layer chromium, wherein the inner layer is milky white Chromium, the outer layer is hard chromium, wherein embodiment three is the best embodiment; during the preparation of electroplating so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com