Method for producing coloured hollow flame-retardant polyester staple fibers

A technology for flame-retardant polyester and its production method, which is applied in the fields of polyester staple fiber, polyester staple fiber and its production, can solve problems such as abnormal product quality or related functions, and rising production costs, and achieve reduction in the amount of color masterbatch, The effect of improving product quality and increasing the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings.

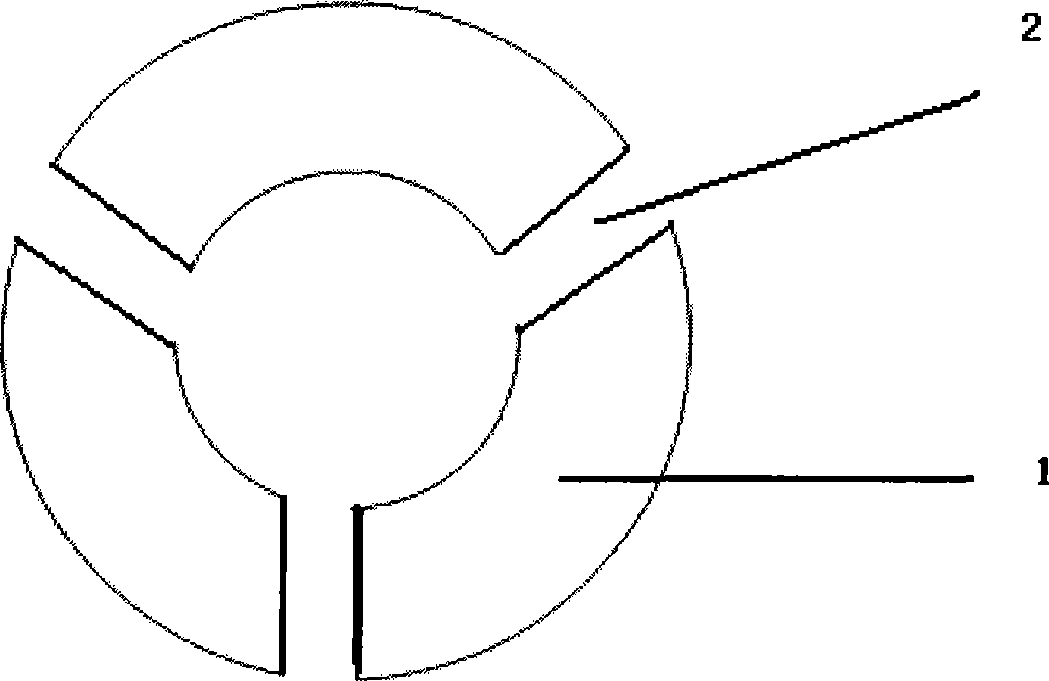

[0014] Spinning on a German Barmag spinning machine, the pump supply rate is 745g / min, the coiling speed is 1050m / min, the spinning temperature is 290°C, and the spinneret adopts 960 holes. Then draw on the LHV3 combined drawing machine of Beijing Zhongli, the drawing ratio is 4 times, and the drawing temperature is 125°C. The color masterbatch and flame retardant masterbatch are melted and extruded by their respective small screws, and then injected into the melt static mixer at a ratio of 0.8% of the total melt mass, and fully mixed with the PET melt for spinning. The main production process The process is: drying→spinning→winding→forming→converging→drawing→crimping→cutting. The shape of the hole on the spinneret is as figure 1 As shown, a product with a specification of 1.67dtex×38mm is finally obtained, and the cross-section of the product is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com