Method for manufacturing plane cocoon fiber nonwoven sheet material

A manufacturing method and technology of cocoon silk, applied in the fields of packaging, health care, industrial filter materials, and hygiene, can solve the problems of non-woven fabric thickness, uneven surface thickness and uneven unevenness, and achieve uniform fiber distribution and smooth surface. Smooth, eco-friendly product

Inactive Publication Date: 2010-12-01

林楠

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Differences: 1. The raw material is curved cocoons, 2. Cocoon peeling is required, 3. Humidification, 4. The cocoon pieces are melted and bonded by sericin, 5. The surface of the non-woven fabric is formed with uneven thickness and unevenness. 6. The non-woven fabric is thicker

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

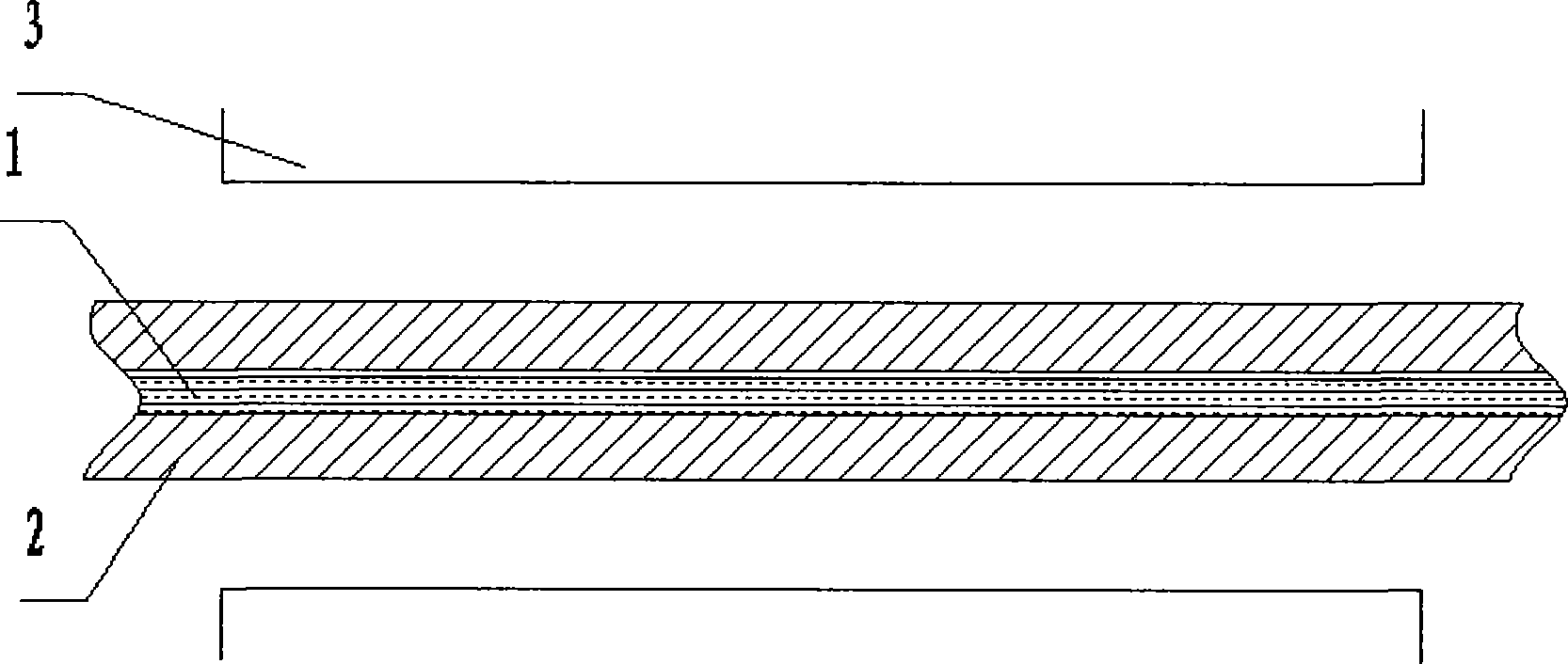

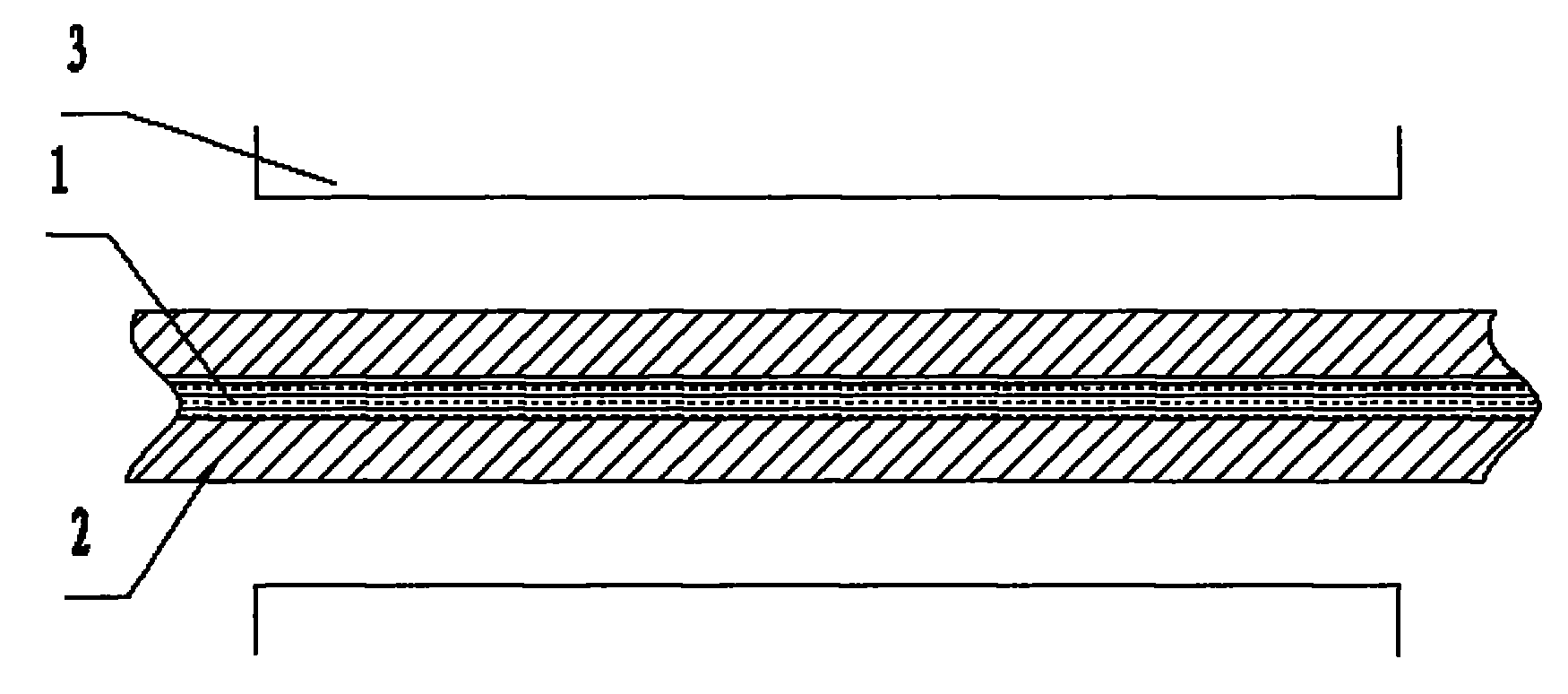

The invention discloses a method for producing a plane cocoon silk nonwoven sheet. The method comprises the following: a plane cocoon silk material is selected as a raw material, is subjected to steps of delamination, edge trimming, paving and thermal setting to form the plane cocoon silk nonwoven sheet. The delaminated cocoon silk is subjected to clearance-type high-temperature hot pressing; andsericin between the cocoon silks is subjected to hot melt and curing to be shaped. During the processing, the plane cocoon silk nonwoven sheet is added with no chemical additive and is a natural purenonwoven sheet. The sheet has evener distribution of cocoon silks, flat and smooth surface, lustrous silk and has the characteristics of thinness and penetration. The sheet has low cost during the processing and no pollution in the production process, can be used as a filtering material, a medical dressing, a cosmetic dressing, a food packaging material and a skin-attaching layer material for a sanitary towel and a protective pad.

Description

Method for manufacturing planar cocoon silk nonwoven sheet technical field The invention relates to a plane cocoon silk non-woven sheet made of plane cocoon silk raw material and a manufacturing method thereof, which is suitable for the fields of health care, sanitation, packaging, industrial filter materials and the like. Background technique Cocoon silk is formed by spinning silkworms and is a natural fiber material. For thousands of years, silkworm cocoons have been spun mainly through reeling, and woven into fabrics to make clothes and bedding. With the increasing development and utilization of silkworm cocoons, silkworm farmers use the characteristics of silkworm cocoons to set limits, and develop flat cocoon silk felt materials, which are composed of cocoon silk gathered in multiple layers. The raw material of the flat cocoon silk felt is relatively thick, and the shape of the cocoon silk aggregates is unstable, and it will tangle after being rubbed. At present, the...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): D06M17/00B01D39/16A61L15/32B65D65/40

Inventor 林楠叶美玲

Owner 林楠

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com