Bidirectional composite force loading test device for masonry test piece

A technology for loading test devices and test pieces, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of less loading devices, difficult test, inconvenient installation of instruments, etc., to meet loading requirements, convenient loading control, and accurate data reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

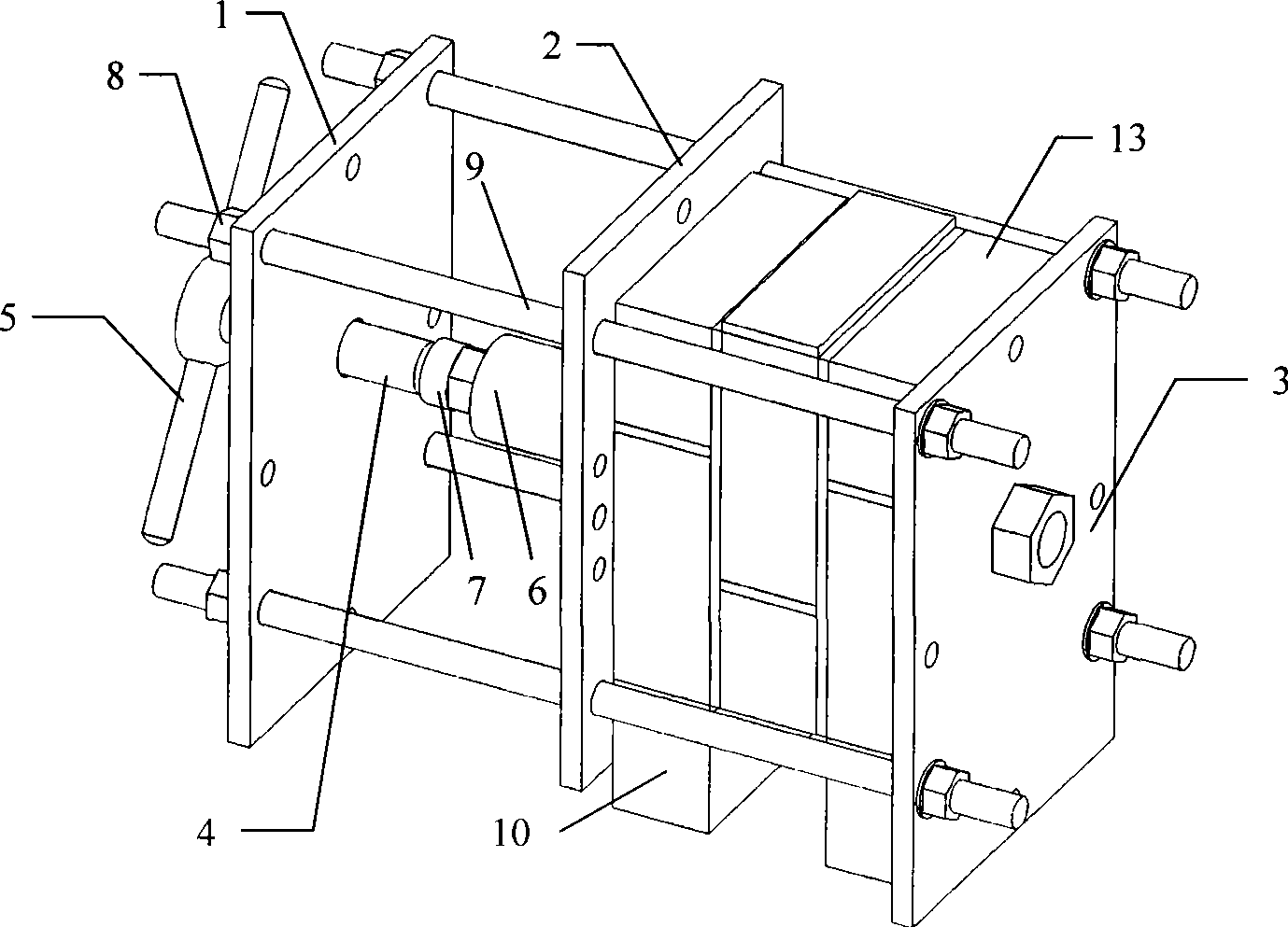

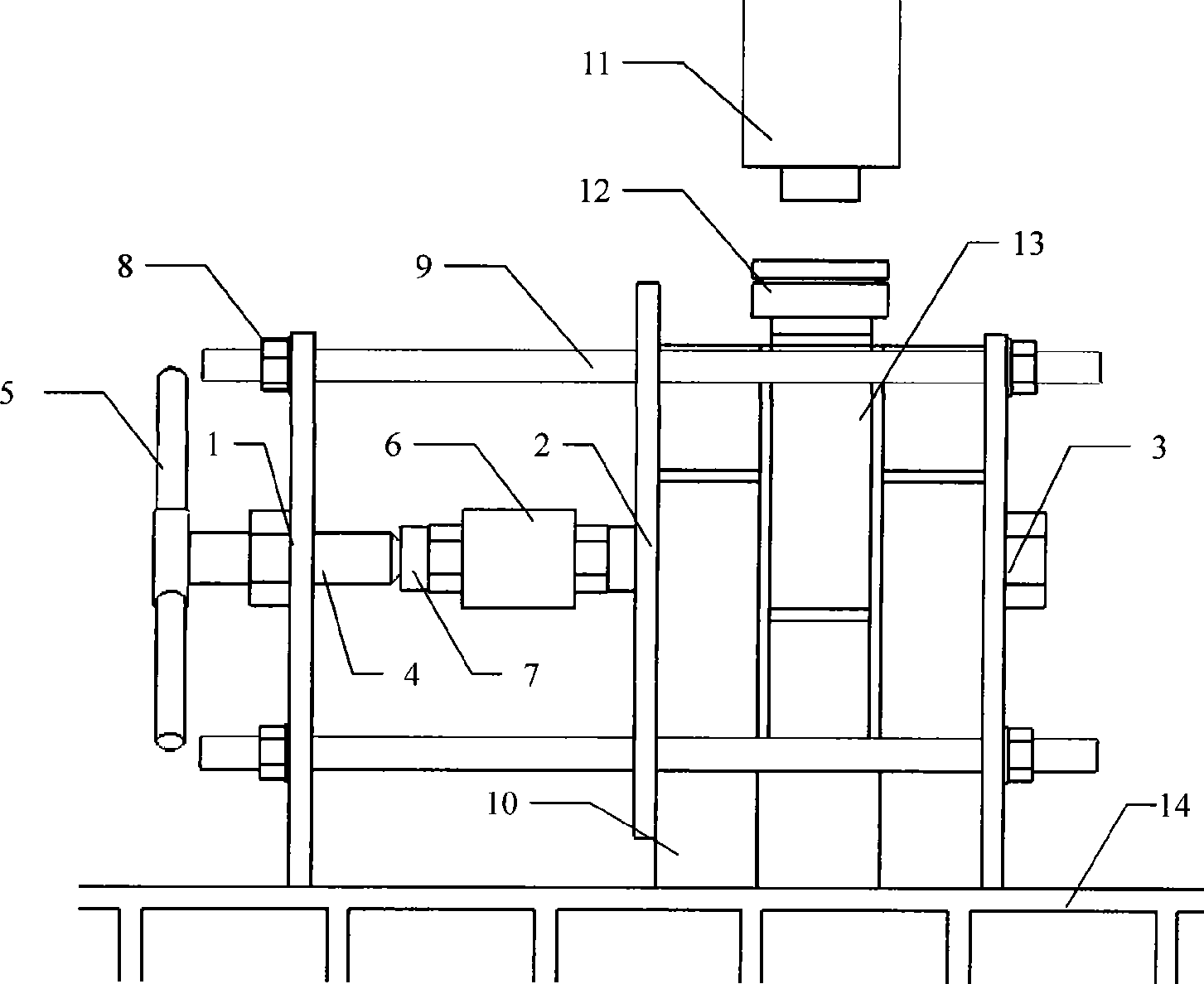

[0030] When the present invention is used as a compression-shear composite force loading device for a masonry double-shear test piece (see for details figure 1 , image 3 and Figure 4 ), the reaction frame is assembled by three steel plates and four screw rods 9, and the four jiaos of the steel plates have circular holes, and the three steel plates are connected by the screw rods through the circular holes. Left and right two steel plates are fixed its relative distance by outer nut 8, and middle steel plate 2 can slide arbitrarily therebetween. Wherein the middle of left steel plate 1 has circular hole and is welded with big nut, and pressure screw rod 4 surface has supporting screw thread and passes through in big nut, and the middle of right steel plate 3 is welded with the nut that is used for balancing bending moment. One end of the pressure screw 4 is torqued by a wrench 5 to achieve manual pressure, and the other end is processed into a hemispherical surface to withs...

Embodiment 2

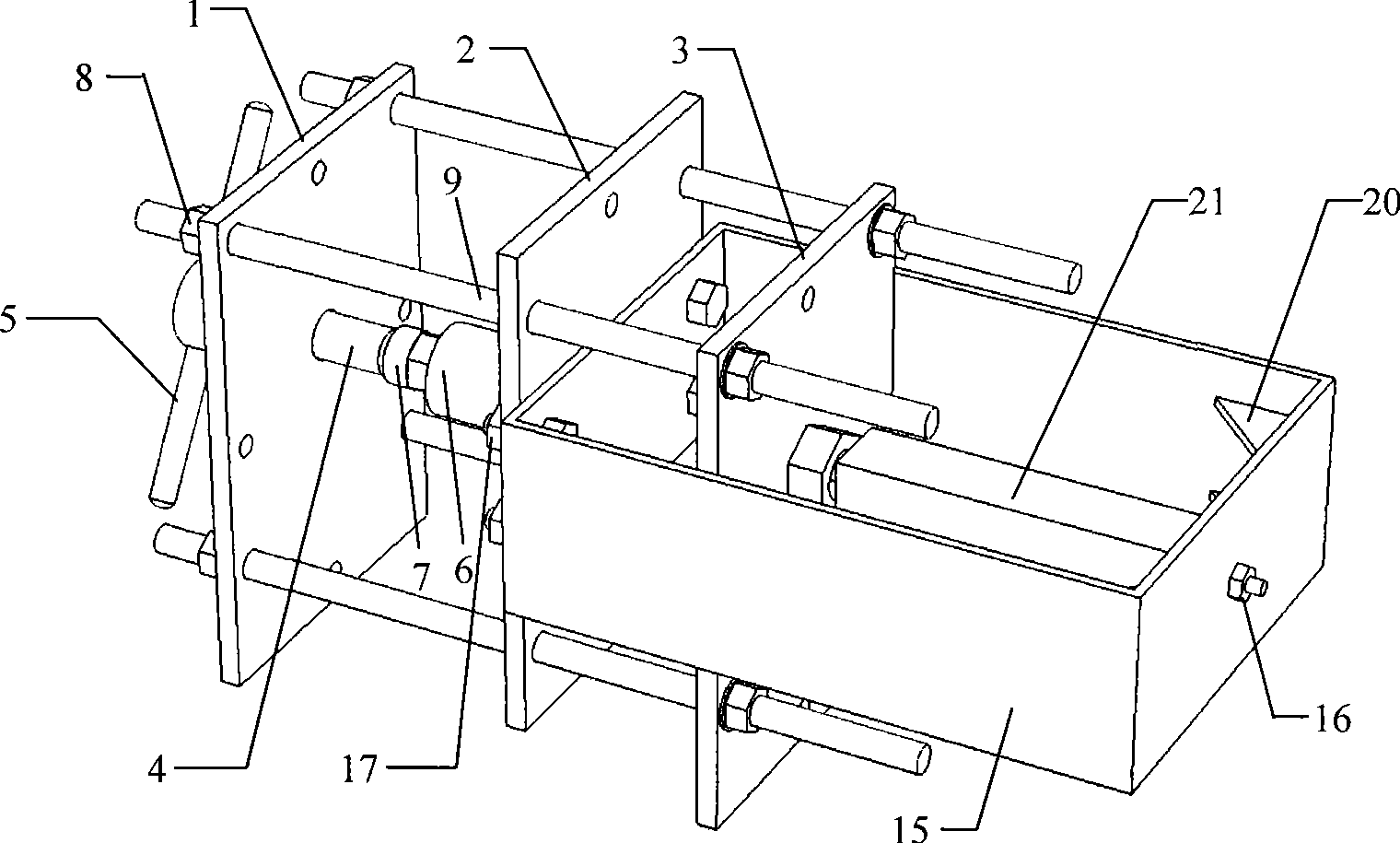

[0039] When the present invention is used as the pull-shear composite force loading device of mortar test block (see for details figure 2 , Figure 5 and Image 6 ), on the basis of the pressure-shear device, a mouth-shaped steel frame 15 is added, on which stiffeners 20 are welded. Fix the square-shaped steel frame 15 on the middle steel plate 2 with bolts 17, which will convert the pressure generated by the pressing screw 4 into the tensile force on the test piece. A small hole is respectively opened in the middle of the right steel plate 3 and the middle of the right side of the mouth-shaped steel frame 15, and the pre-embedded steel bars at both ends of the mortar test block 21 pass through respectively, and are fixed with nuts 16 (threads are processed at the ends of the steel bars in advance) .

[0040] In order to carry out the tensile-shear composite stress loading test of mortar test block and other specimens, the present invention can complete the loading task ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com