Cooling system for testing longevity of hybrid vehicle controller

A technology for vehicle controllers and hybrid electric vehicles, applied in general control systems, engine cooling, control/regulation systems, etc., can solve problems such as controller and motor burnout, failure, and unstable operating temperature of hybrid electric motors. Achieve the effect of low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

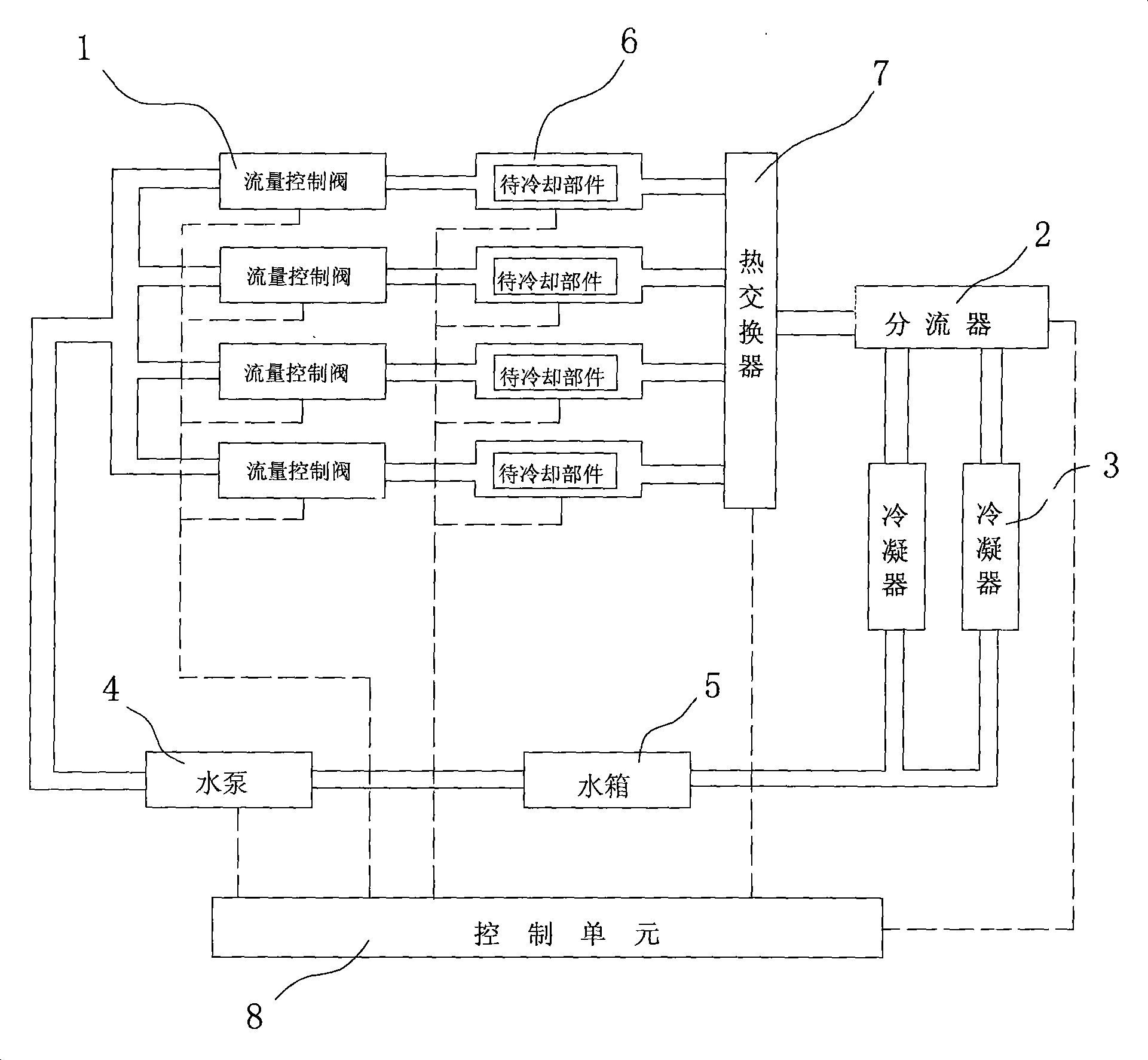

[0019] Such as figure 1 As shown, the cooling system used for the life test of the hybrid vehicle controller in this embodiment includes a control unit 8, four flow control valves 1, a water pump 4, a flow divider 2, two condensers 3, a water tank 5 and four A cooling bench 6 provided with a temperature sensor, and a communication cable is connected between the control unit 8 and the temperature sensor, the water pump 4, the flow control valve 1 and the shunt 2 of the cooling bench 6 (the communication cable is connected with the dotted line in the figure). express).

[0020] The water pump 4 is connected to the water tank 5 by pipelines, and the cooling water pumped from the water tank 5 by the water pump 4 is distributed to a plurality of flow control valves 1, and each flow control valve 1 is connected to a hollow cooling stand 6 for placing components to be cooled. connected, the cooling water flows from the flow control valve 1 to the corresponding cooling stand 6, and c...

Embodiment 2

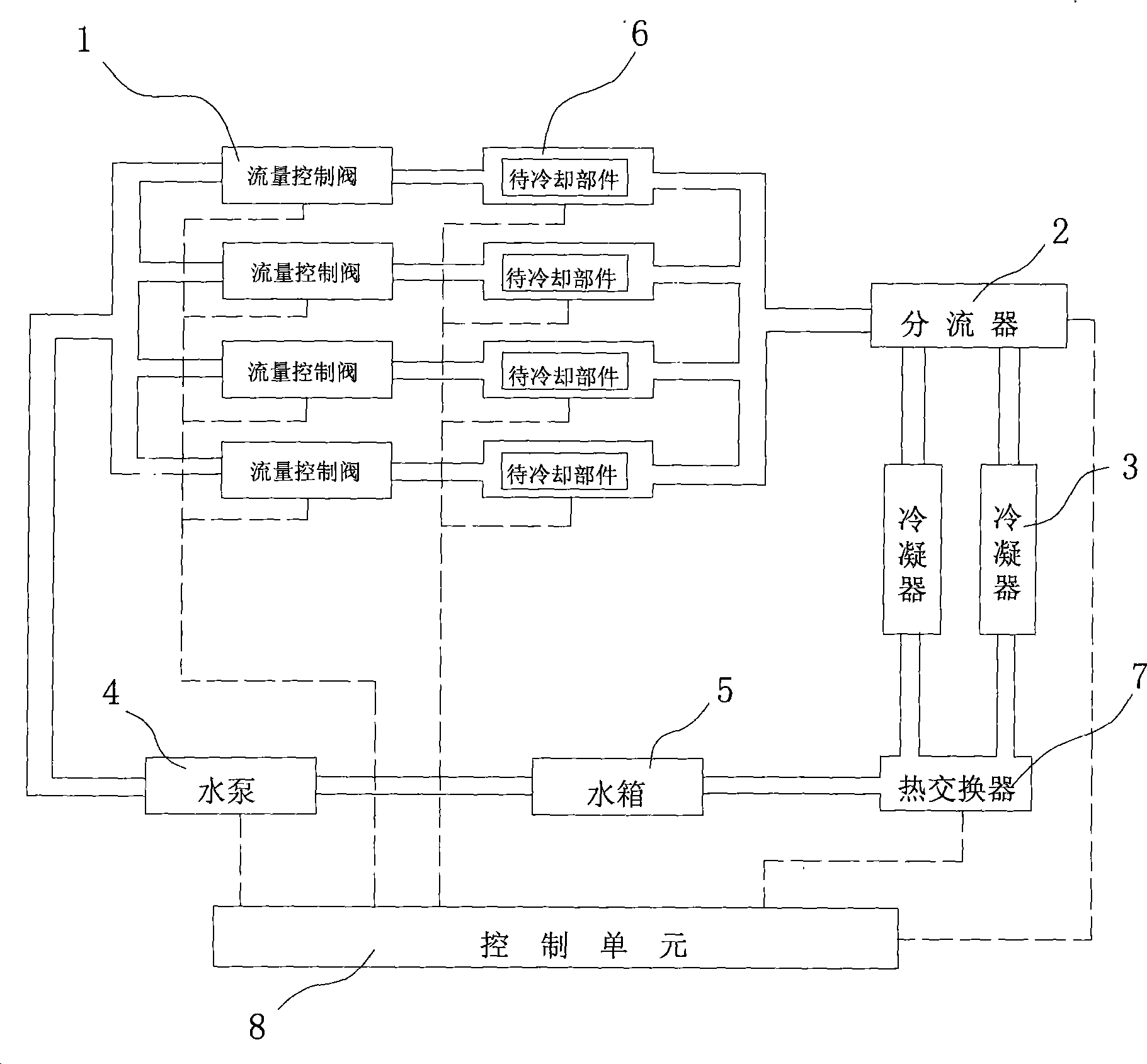

[0023] Such as figure 2 As shown, different from the above-mentioned embodiment 1, the heat exchanger 7 of this embodiment is arranged at the position between the condenser 3 and the water tank 5, and the cooling water flowing out of the cooling platform 6 passes through the condenser 3 First pass through the heat exchanger 7, and then return to the water tank 5, which can also achieve the purpose of accelerating the heat exchange of cooling water, so as to adapt to the large difference in the length of the cooling water circulation path where each condenser 3 is located in some vehicle test systems. Case.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com