Method for treatment of sludge or wastewater

A treatment method and technology for wastewater, applied in sludge treatment, sludge treatment, water/sludge/sewage treatment, etc., can solve the problem of low efficiency of flocculation sludge dewatering treatment, and achieve the goal of inhibiting deterioration and exerting flocculation performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

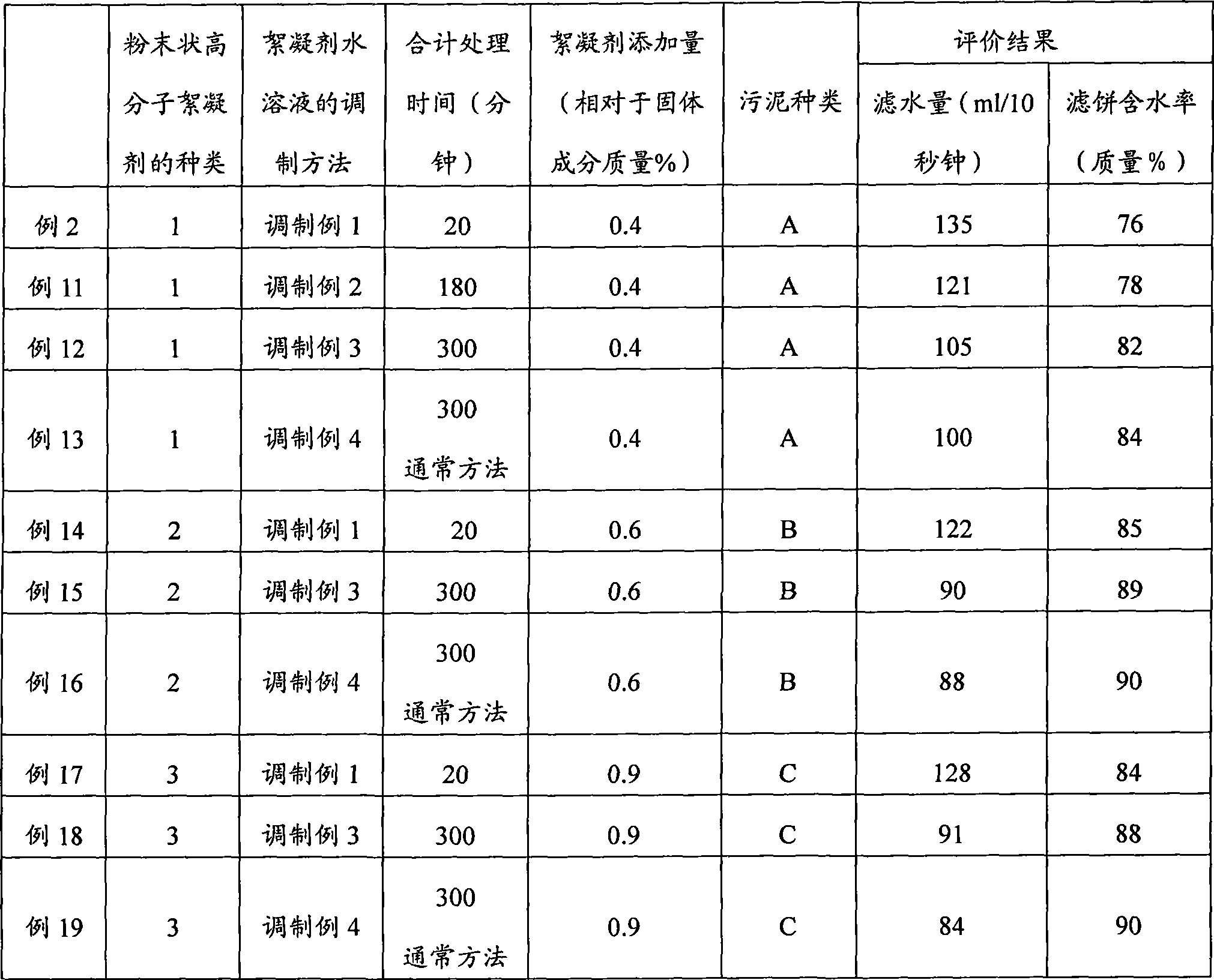

[0090] Hereinafter, although an Example demonstrates this invention in more detail, it is not limited to this range in the range which does not deviate from the summary of this invention.

[0091]

[0092] (modulation example 1)

[0093] The preparation and supply of the flocculant aqueous solution is carried out using a rotary flocculant continuous dissolving supply device, the device has: a cylindrical filter member with a filter surface having a mesh of 200 μm in the peripheral surface; the inner surface connected to the peripheral surface of the filter member A roller made of elastic body that rotates; a pump that transports the aqueous flocculant solution that passes from the inside of the filter member to the outside. That is, while stirring the well water, a polymer flocculant was added thereto at a constant rate to a concentration of 0.2% by mass, and then the stirring was stopped to allow swelling. The swollen swelling liquid is supplied to the inner side of the fi...

example 1~5

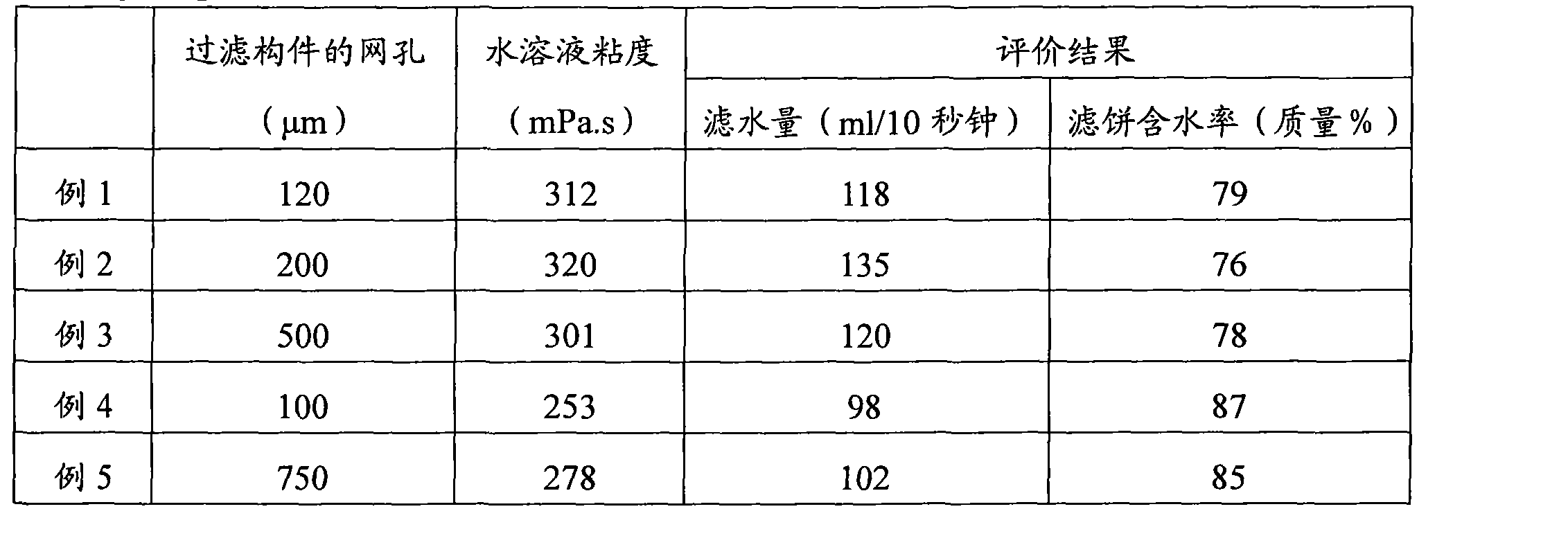

[0124] Using the powdery polymer flocculant 1, an aqueous flocculant solution was prepared in the same manner as Preparation Example 1, and a flocculation dehydration test was performed using sludge A. Here, the mesh of the filter member was changed as shown in Table 3. The amount of the aqueous flocculant solution added to the sludge A was set so that the concentration of the polymer flocculant relative to the solid matter (the same applies hereinafter) was 0.4% by mass.

[0125] Table 3 shows the evaluation results of drainability (filtered water amount) and dewaterability (cake water content). In addition, the viscosity of the prepared aqueous flocculant solution was measured at 12 rpm with a Brookfield type rotational viscometer in a constant temperature tank at 25°C, and the results are shown in Table 3.

[0126] [table 3]

[0127]

[0128] From the results in Table 3, the drainage of the sludge flocculation treatment in Examples 1 to 3 and the dewaterability of the ...

example 6~11

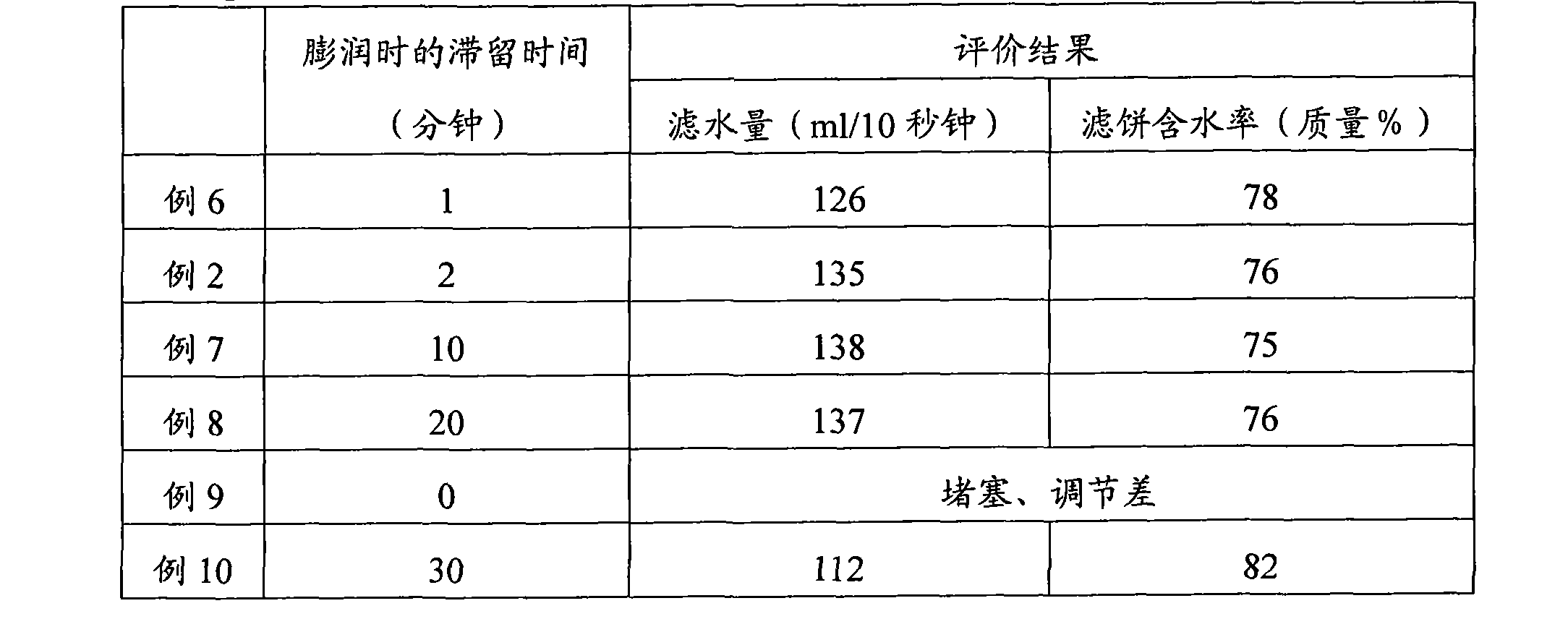

[0130] Using the powdery polymer flocculant 1, an aqueous flocculant solution was prepared in the same manner as Preparation Example 1, and a flocculation dehydration test was performed using sludge A. Here, after adding the powdery polymer flocculant to water and stirring, the residence time during swelling was changed as shown in Table 4 by adjusting the swelling time before filtration. The quantity of the aqueous flocculant solution added to sludge A was the same as Examples 1-5, and it was 0.4 mass % with respect to solid matter. The same evaluations as in Examples 1 to 5 were performed, and the results are shown in Table 4. Combine the results of Example 2 to show.

[0131] [Table 4]

[0132]

[0133] From the results in Table 4, in Examples 2 and 6 to 8 in which the residence time at the time of swelling was 1 to 20 minutes, the drainage in the sludge flocculation treatment and the dehydration property of the flocculated sludge were excellent. Example 9 is an examp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com