A kind of preparation method of hydrophilic polymer microporous filter material

A hydrophilic polymer and microporous filtration technology, applied in the field of porous materials, can solve the problems of application limitations and lack of effective means, and achieve the effects of uniform pore size distribution, thorough removal, and huge application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Add 100 g of polyvinyl alcohol with a degree of polymerization of 1799 into 750 mL of water under stirring, and gradually raise the temperature to 90° C. until the polyvinyl alcohol is completely dissolved.

[0035] When the temperature of the polyvinyl alcohol solution drops to 50°C, slowly add 180mL of 40% sulfuric acid, and the temperature of the system will rise at this time, and when the temperature drops back to 50°C, add 100mL of formaldehyde to carry out the acetalization reaction. After 10 minutes, add 20 mL of o / w emulsion of kerosene, the mass fraction of kerosene in the emulsion is 40%. Stir quickly to disperse the emulsion evenly in the colloidal phase. Then, the material mixture was poured into a plastic mold, and treated at a temperature of 50° C. for 12 hours. Finally, the mold is opened, the molding is taken out, and the residue is removed by washing with water.

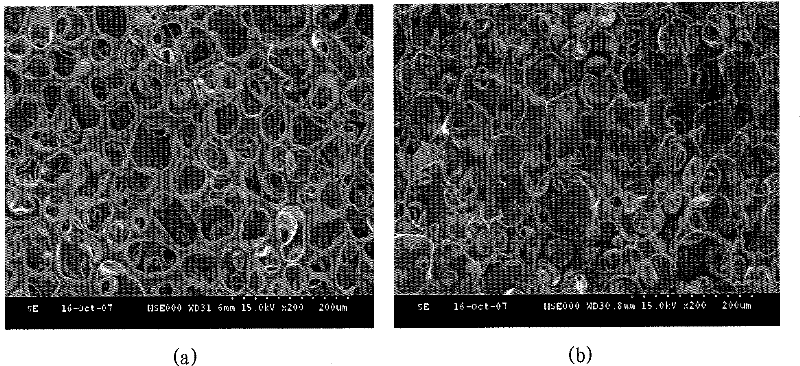

[0036] SEM photographs of the materials are attached figure 1 As shown, the pore size d...

Embodiment 2

[0038] Add 100 g of polyvinyl alcohol with a degree of polymerization of 1799 into 750 mL of water under stirring, and gradually raise the temperature to 90° C. until the polyvinyl alcohol is completely dissolved.

[0039] When the temperature of the polyvinyl alcohol solution drops to 50°C, slowly add 180mL of 40% sulfuric acid and 100mL of formaldehyde, and react for 10 minutes, then add 5mL of kerosene o / w emulsion. After stirring evenly, pour the material into the prepared plastic mold and treat at 50°C for 12 hours. The mold is opened, and the material taken out is washed with water to remove residues to obtain a cross-linked polyvinyl alcohol microporous material.

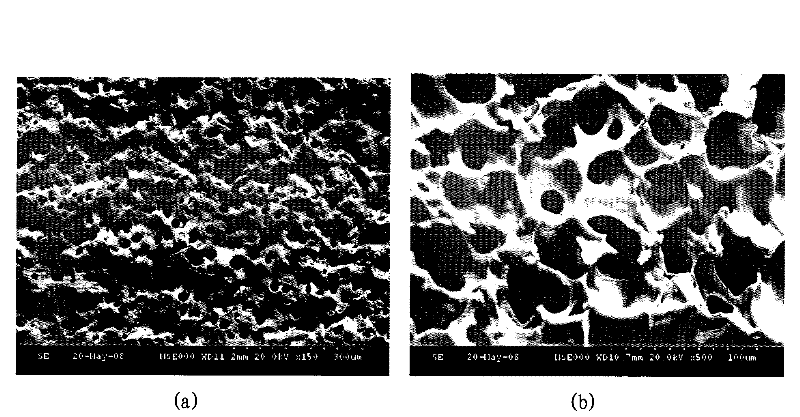

[0040] SEM photographs of the materials are attached figure 2 As shown, the structure of the obtained material is similar to that obtained in Example 1. Its porosity is 88%, the maximum pore diameter measured by bubbling method is 8.64μm, and its clear water flux is 2625.0L / m under the pressure head of 1.2...

Embodiment 3

[0042] By the same method of embodiment 2, the addition of emulsified kerosene is changed to 45mL, and other compositions and operating methods are unchanged.

[0043] The obtained microporous polyvinyl alcohol material has a porosity of 90%, a maximum pore diameter of 7.30 μm measured by the bubbling method, and a clear water flux of 2176.0 L / m under a water column pressure head of 1.2 m 2 h. Use 24.5g / L ultra-fine calcium carbonate suspension as the filter material, the outlet pressure head is 1.2m water column, and some particles leak through.

[0044] The scanning electron microscope photograph of the material is as image 3 As shown, the pore structure is quite different from the materials obtained in the first two examples, the pore support is thin-walled, and the penetration of the channel is relatively low.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com