Precision roll turning lathe

A roll lathe, precision technology, applied in the field of precision roll lathe, can solve the problem of reduced machining accuracy, and achieve the effect of shortening time, high efficiency, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

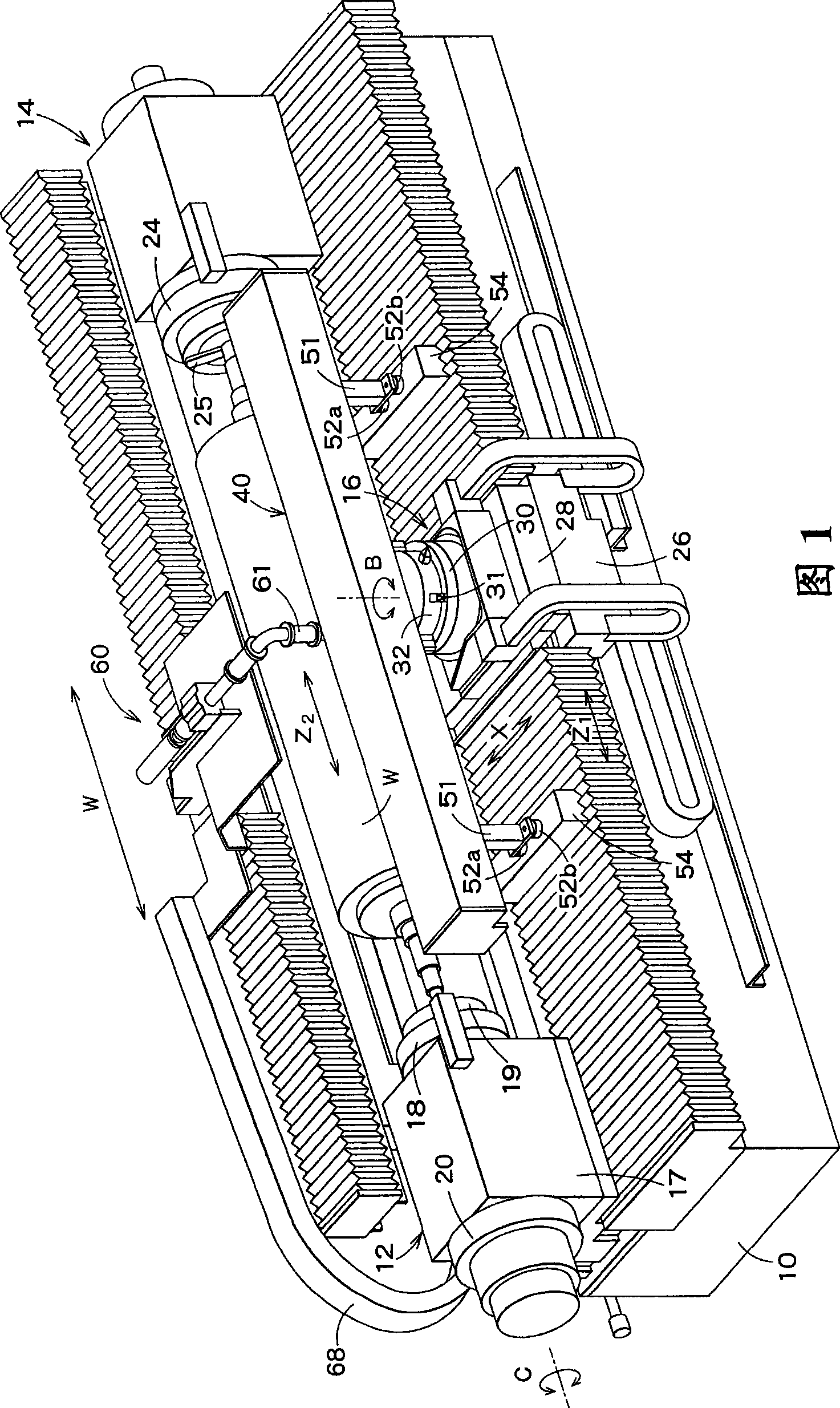

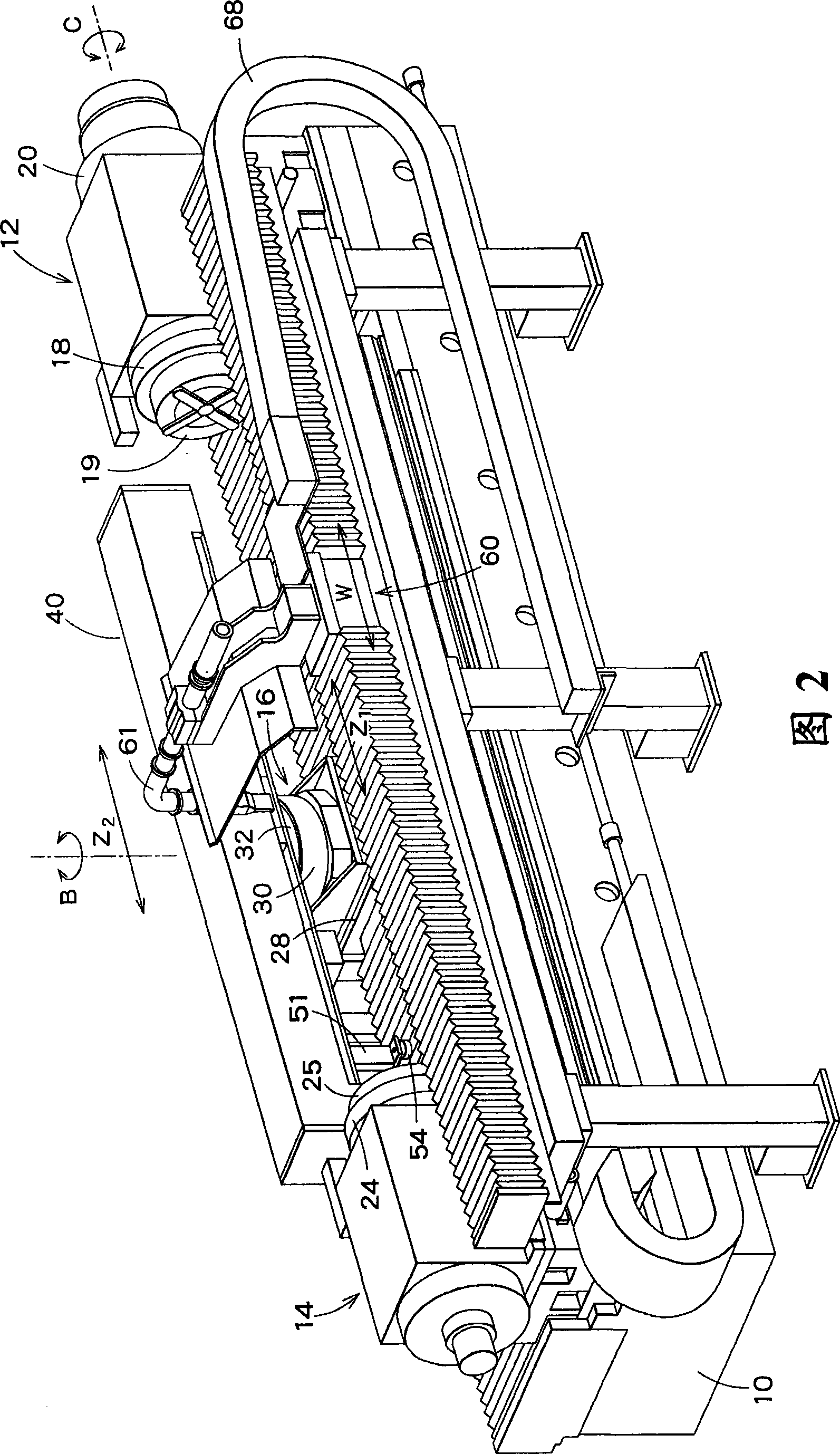

[0029] 1 is a front perspective view of a precision roll lathe according to a first embodiment of the present invention, and FIG. 2 is a rear perspective view of the precision roll lathe without a roll installed.

[0030] In Fig. 1 and Fig. 2, numeral 10 denotes a bed. A headstock 12 , a tailstock 14 and a support 16 are installed on the bed 10 . A roll W as a workpiece is rotatably supported by the headstock 12 and the tailstock 14 .

[0031] The head box 12 is located at one end of the bed 10 in the longitudinal direction. The headstock 12 includes a box body 17 , a main shaft 18 , a chuck 19 fixed on the front end of the main shaft 18 and a servo motor 20 for driving the main shaft 18 . The main shaft 18 is supported by a hydrostatic oil bearing (not shown) provided in the case 17 . The chuck 19 holds the spindle of the roll W, and transmits the rotation of the spindle 18 to the roll W. As shown in FIG.

[0032] In the headstock 12 , the servo motor 20 for driving the m...

no. 2 example

[0067] Now, a precision roll lathe according to a second embodiment of the present invention will be described with reference to FIG. 7 .

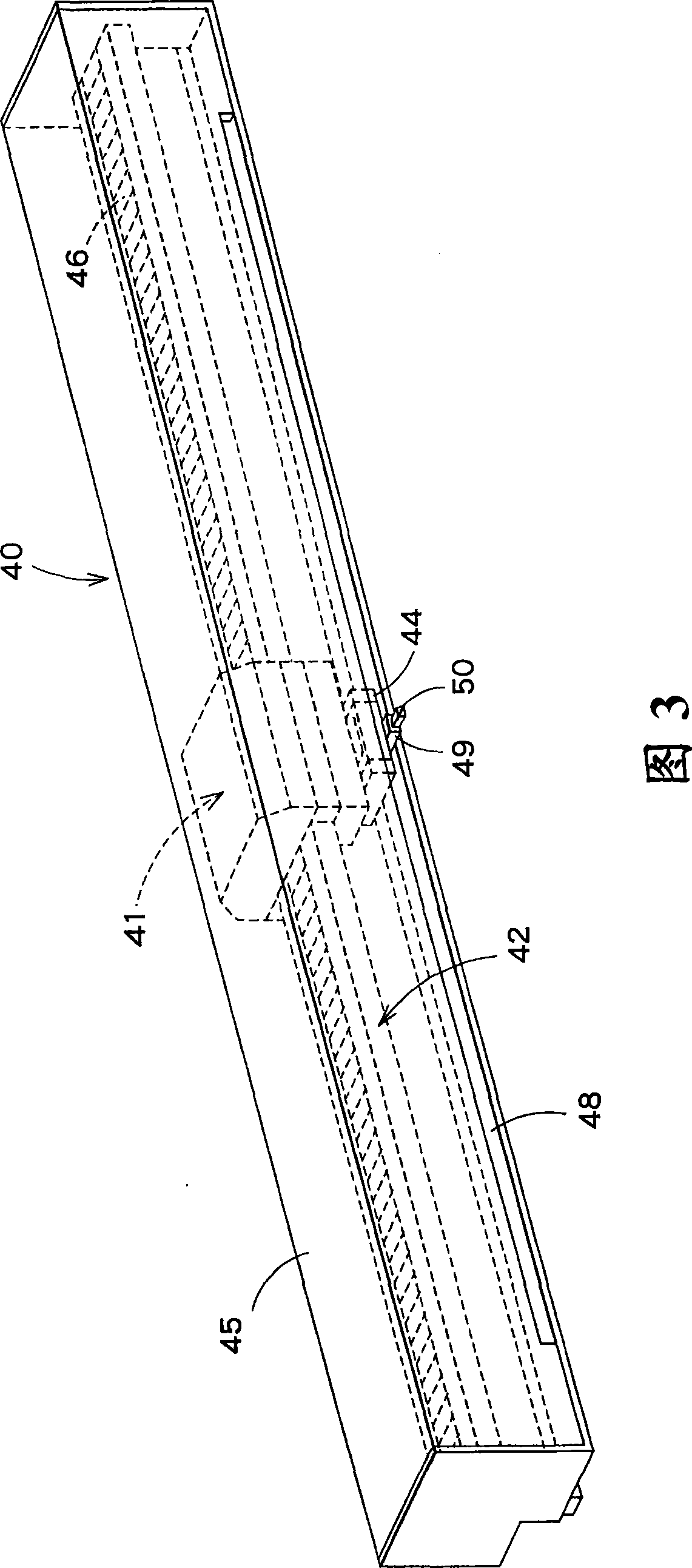

[0068] The roll lathe of this embodiment is characterized in that a chip suction device 60 shown in FIG. 7 is provided. As shown in FIG. 7 , the chip suction device 60 includes a moving table 61 and a support arm 62 . The moving table 61 moves on the bed 10 in a direction parallel to the moving direction of the slider 41 . A ball screw is used as a driving mechanism of the moving table 61, and a W-axis is used as a control axis of the driving mechanism.

[0069] The support arm 62 is fixed on the moving table 61 , and the support arm 62 extends toward the roller W. As shown in FIG. The suction duct 63 is supported by a support arm 62 . A joint 64 is mounted on the downwardly bent end of the suction duct 63 , and a suction nozzle 65 is connected to the suction duct 63 via the joint 64 . The tip of the suction nozzle 65 is located near t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com