Composite film for hermetic food heating automatic pressure-regulation packaging device and manufacture method thereof

An automatic pressure-regulating, air-tight technology, applied to food heating containers, packaging under vacuum/special atmosphere, packaging objects under special gas conditions, etc., can solve the problems of short effective storage period, albinism and frostbite, and prolonging the shelf life of food, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

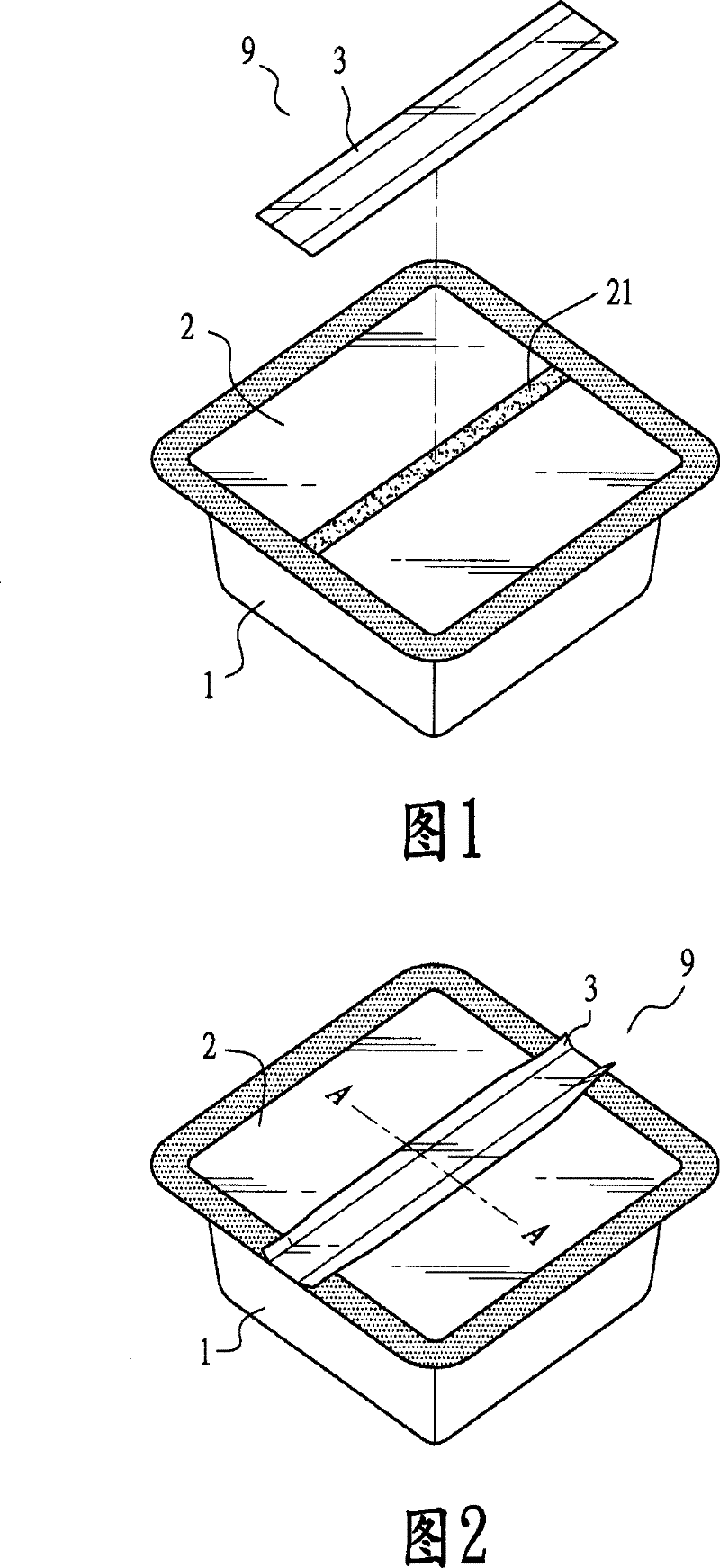

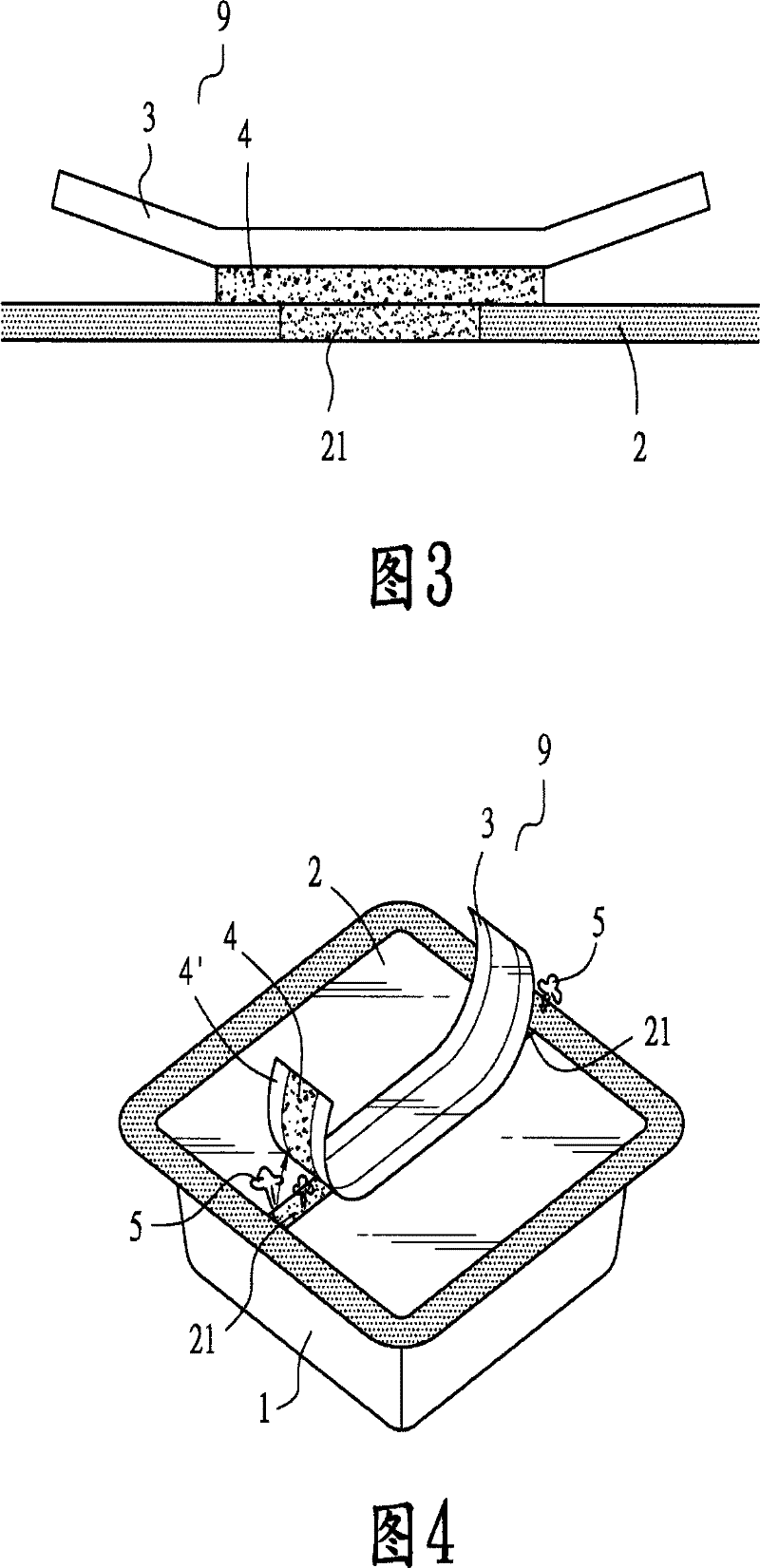

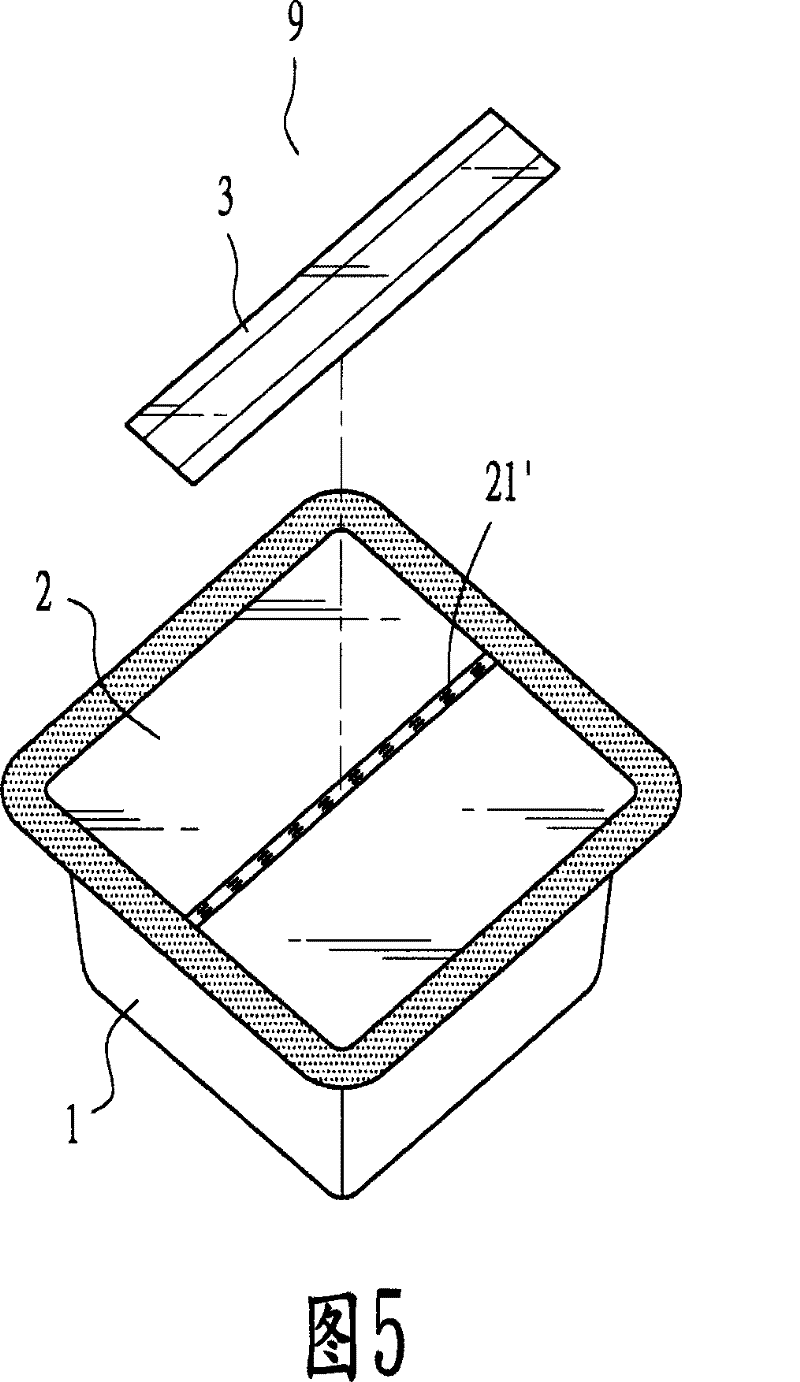

[0045] Such as figure 1 As shown, the composite film for the airtight food heating and automatic pressure regulating packaging device of the present invention is coated with an airtight substrate film layer 2 by hot pressing at the opening end of the packaging box 1 for packaging various frozen and refrigerated foods. Before the substrate film layer 2 is covered and bonded, a microscopic gap structure region 21 of a predetermined range and size can be processed through a rolling process; in this embodiment, the microscopic gap structure region can be arranged in any direction. The microscopic gap structure area on the package can also be as Figure 5 As shown, it is arranged in the form of line-segment microscopic gap structure regions 21' arranged in the same direction at discontinuous intervals. According to the width of the microscopic gap structure region 21 of the substrate film layer 2, the sealing tape 9 greater than this range is determined, and the sealing tape 9 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com