Seeding apparatus

A seed metering device and seed metering trough technology are applied in the directions of sowing planters, planter parts, fertilization devices, etc., which can solve the problems of poor seed metering stability, high production cost, and irregular seedling emergence, and achieve easy layout and simple structure. , the effect of high seeding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

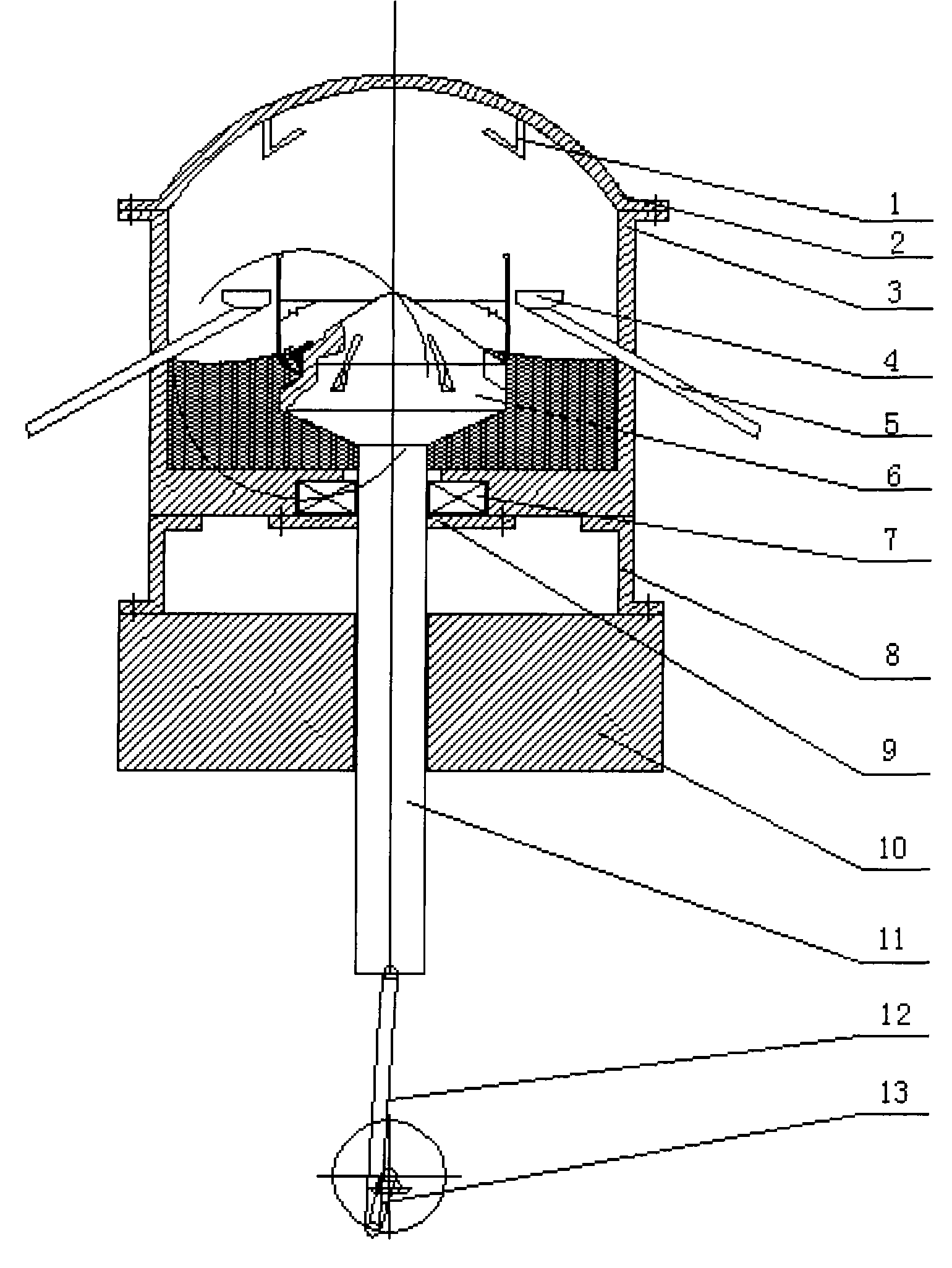

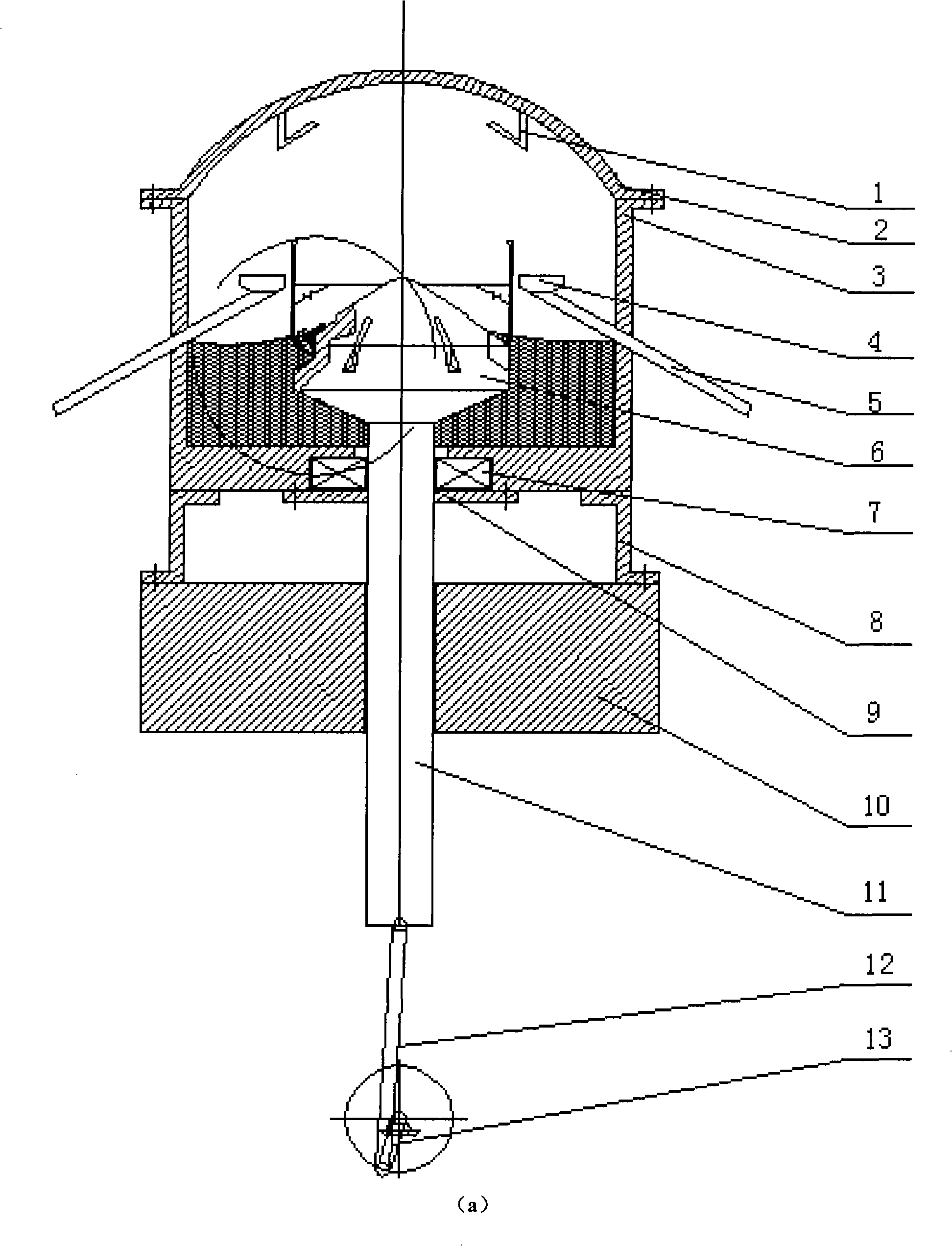

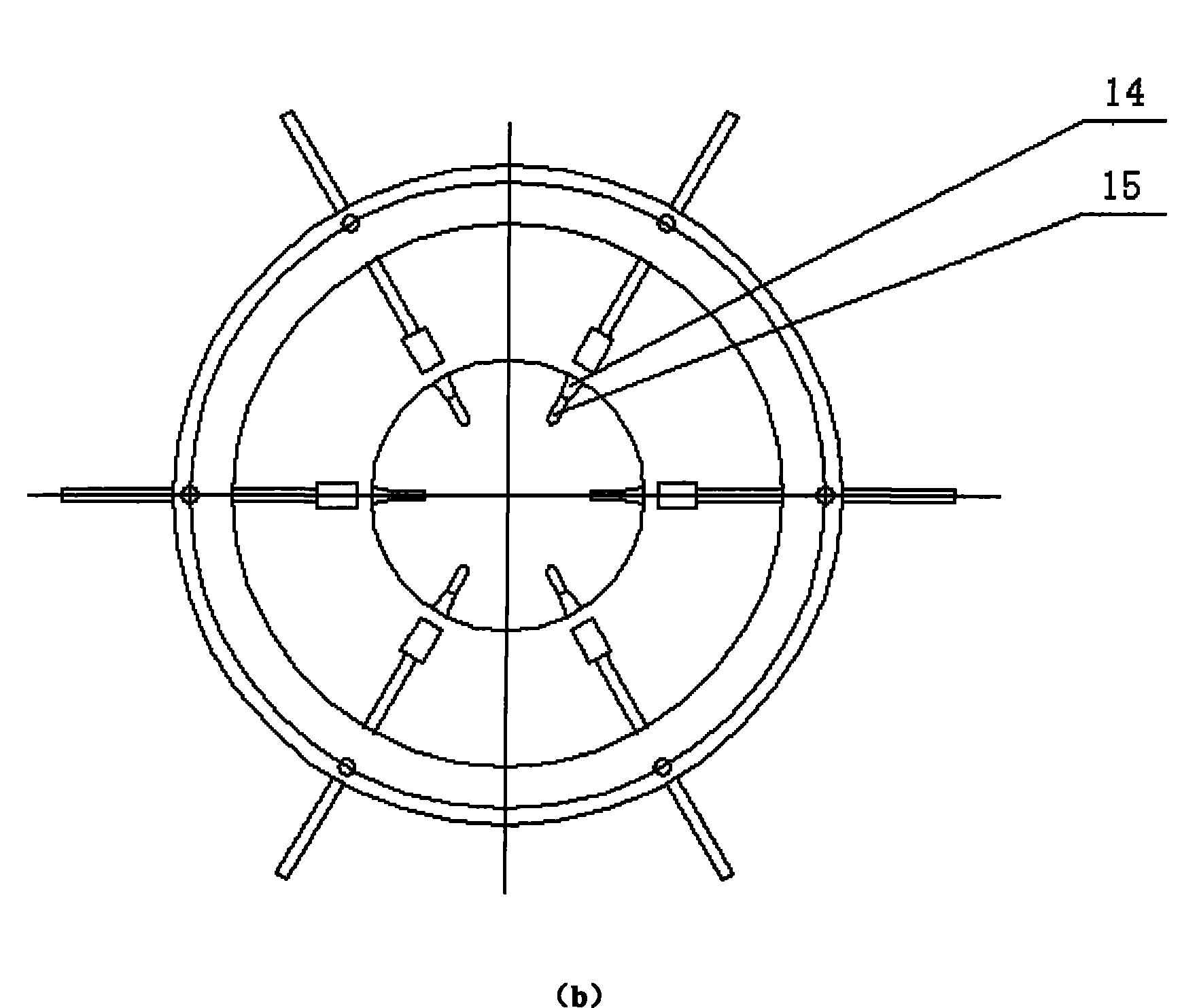

[0026] In conjunction with Fig. 1, Fig. 2, Fig. 3, and Fig. 4, its implementation process is as follows:

[0027] First, the external power drives the crank 13 to perform circular motion, and the crank 13 drives the connecting rod piston 6 to perform reciprocating linear motion. In order to ensure the reliability of the linear movement of the piston 6, and at the same time ensure that there is enough space on the upper surface of the piston to arrange the seeding groove, it is designed to connect a thin rod 11 under the big head of the upper end; in addition, to ensure the straightness of the piston, the thin rod 11 is placed in a stroke Longer piston sleeve 10 miles. In order to prevent the gap between the thin rod 11 and the seed box 3 from leaking seeds, a wear-resistant gasket 7 is added between the thin rod 11 and the bottom of the case, and the outer end of the gasket 7 is blocked by a cover plate 8. Therefore lengthened piston sleeve 10 and wear-resistant washer 7 can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com