Spraying apparatus of zinc electrolyte cooling column

A technology of zinc electrolyte and spraying device, which is applied in the direction of water shower coolers, photographic technology, lighting and heating equipment, etc., can solve the problem that the processing capacity of the zinc electrolysis device has a great influence on the production capacity, affects the overall production capacity of the zinc electrolysis device, The processing capacity of the cooling system has not reached and other problems, to achieve the effect of improving production processing capacity, reducing labor intensity of employees, and less crystallization nuclei

Active Publication Date: 2010-08-18

ZHUZHOU SMELTER GRP

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

1. The overall weight of the sprinkler device will increase after the crystals are attached to the pipe, making it difficult to lift, and there will be safety hazards during cleaning and lifting;

2. It requires a large work site, and the labor intensity of the operators is high;

3. During the cleaning process, due to the brittle material of PVC (polyvinyl chloride), the repair rate in operation is as high as 87%, and the loss is serious

The processing capacity of the cooling system has a great influence on the production capacity of the zinc electrolysis device. The existence of the above problems has caused the processing capacity of the cooling system to not reach its rated load, which seriously affects the overall production capacity of the zinc electrolysis device. Improve

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

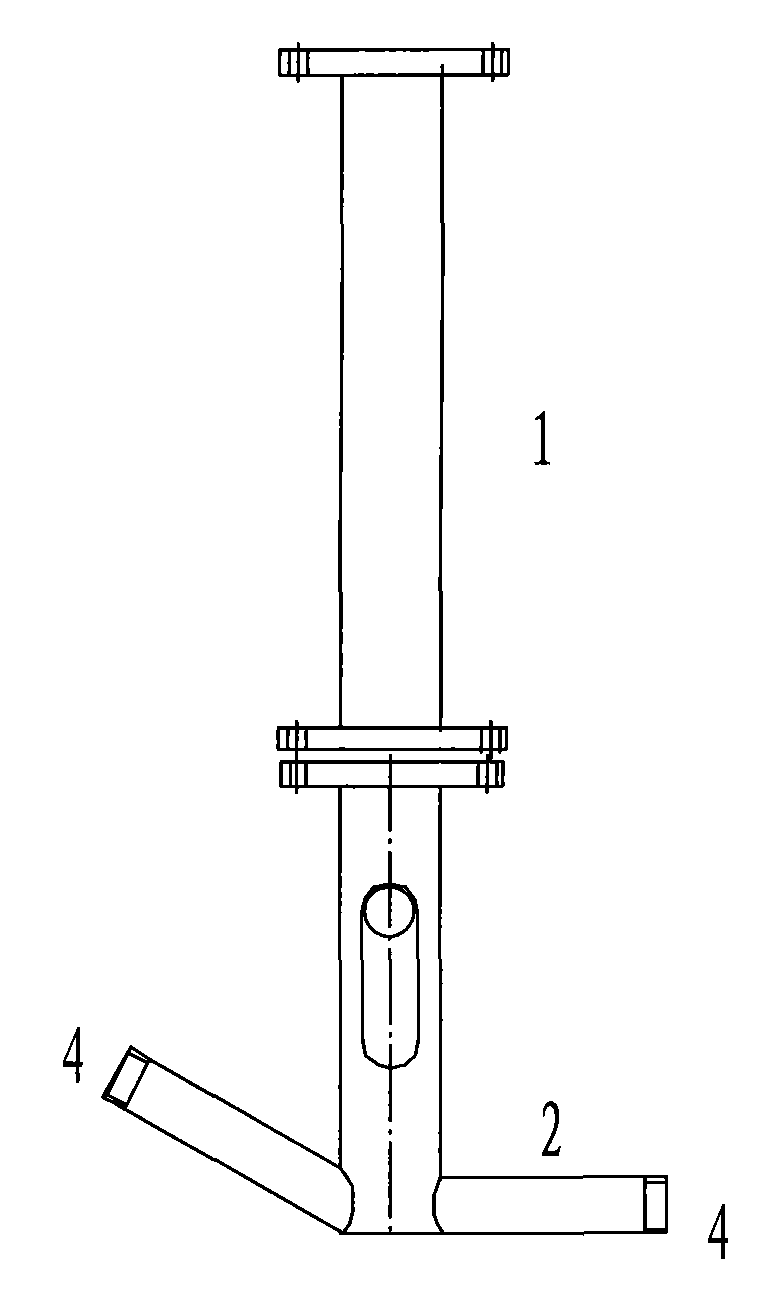

The invention relates to an electrolyte cooling device in a zinc hydrometallurgy device. The device adopts a technical proposal that a spray device of a zinc electrolyte cooling tower comprises more than ten branch pipes, spray racks arranged on the lower ends of the branch pipes, and 4 spray nozzles arranged on each spray rack, wherein the branch pipes are evenly distributed in the upper space of a tower body, are communicated with a liquid inlet main pipe, and are extended downwardly and vertically; and the spray nozzles are arranged at certain intervals and face different directions. The electrolyte cooling device is characterized in that the branch pipes and the spray racks are made of polypropylene. One of four small branch pipes is in a horizontal status; and the other three small branch pipes are arranged at 15 to 30 degrees to the horizon. Through improving the material of spray pipes, the electrolyte cooling device reaches the effect of improving the surface fineness inside the pipes, brings about high fineness inside the pipes, few host crystals, and smaller adhesion to the crystals than that of PVC, greatly reduces the adhesive rate of the crystals, reduces the adhesionspeed of the crystals, and reduces the reduction speed of the effective diameter of each pipe. In addition, the crystals are easy to fall off. The crystals fall off in blocks with a sight shock from an external force and are easy to be collected.

Description

technical field The invention relates to a metal smelting equipment, in particular to an electrolyte cooling device in a wet zinc smelting equipment. Background technique Zinc hydrometallurgy is a general process of zinc smelting. In its electrolysis process, the zinc electrolyte produced needs to be cooled, usually by air cooling. The high-temperature waste liquid after electrolysis is transported to the top of the cooling tower through pipelines, and then The waste liquid is sprayed by the cooling tower spray device to form a mist spray liquid, which is cooled by air through convection. The structure of a commonly used cooling tower is: a rectangular parallelepiped tower with a length of about 10m, a width of about 5m and a height of about 12.5m is formed by a plurality of glass steel plates. At the top, the liquid flows from top to bottom, and the gas flows from bottom to top, exchanging heat by convection. The composition of the spraying device is: a plurality of branc...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): F28F25/04C25C1/16F28C1/02

CPCY02P10/20

Inventor 姚昌洪祝昶李湘平

Owner ZHUZHOU SMELTER GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com