Ammonia circulating vaporization method and its electric heating carburetor

A carburetor and electric heating technology, applied to the method of container discharge, pressure vessel, equipment discharged from the pressure vessel, etc., can solve the problems of customer shutdown, failure to transport, damage, etc., and achieve the effect of saving water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

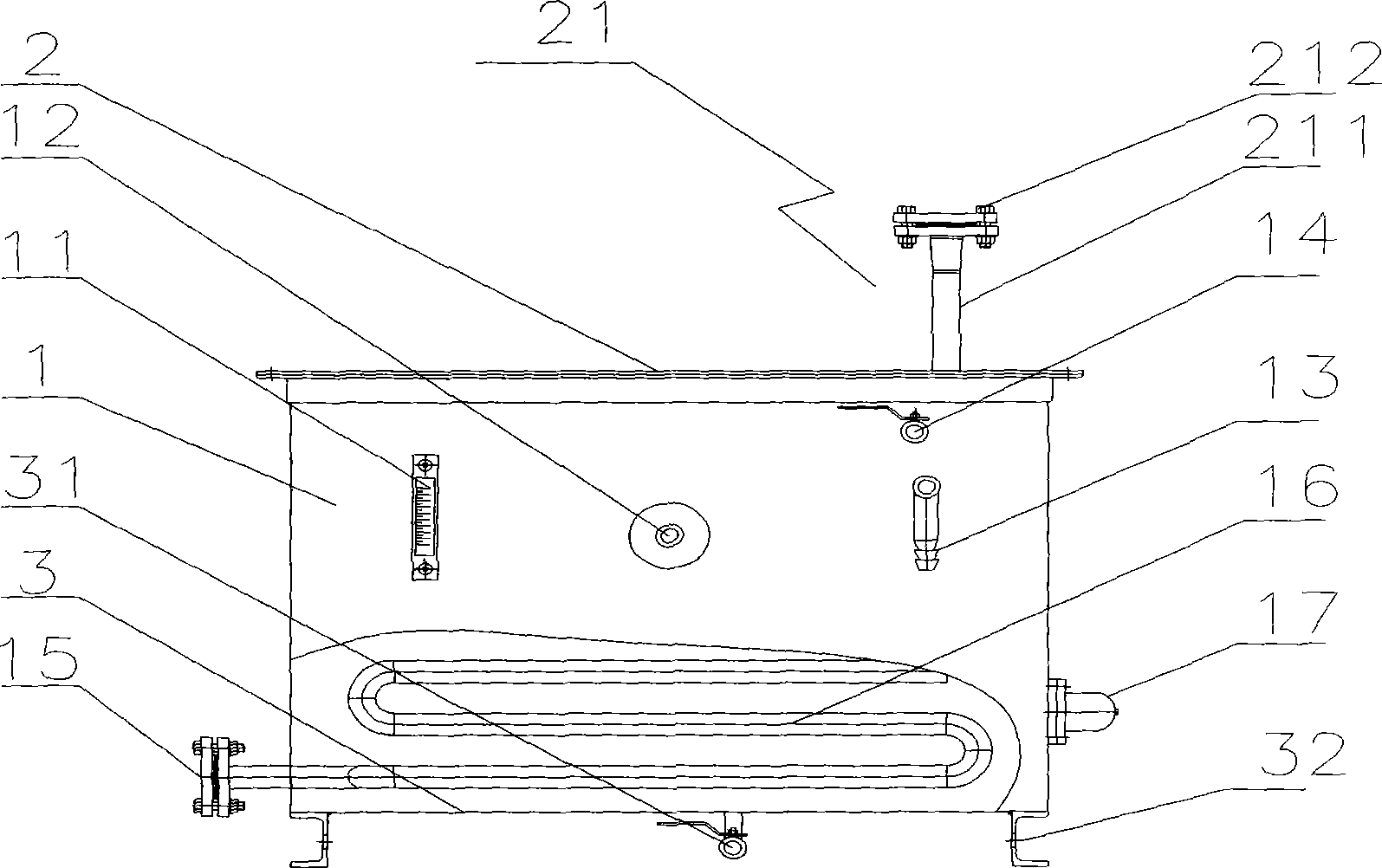

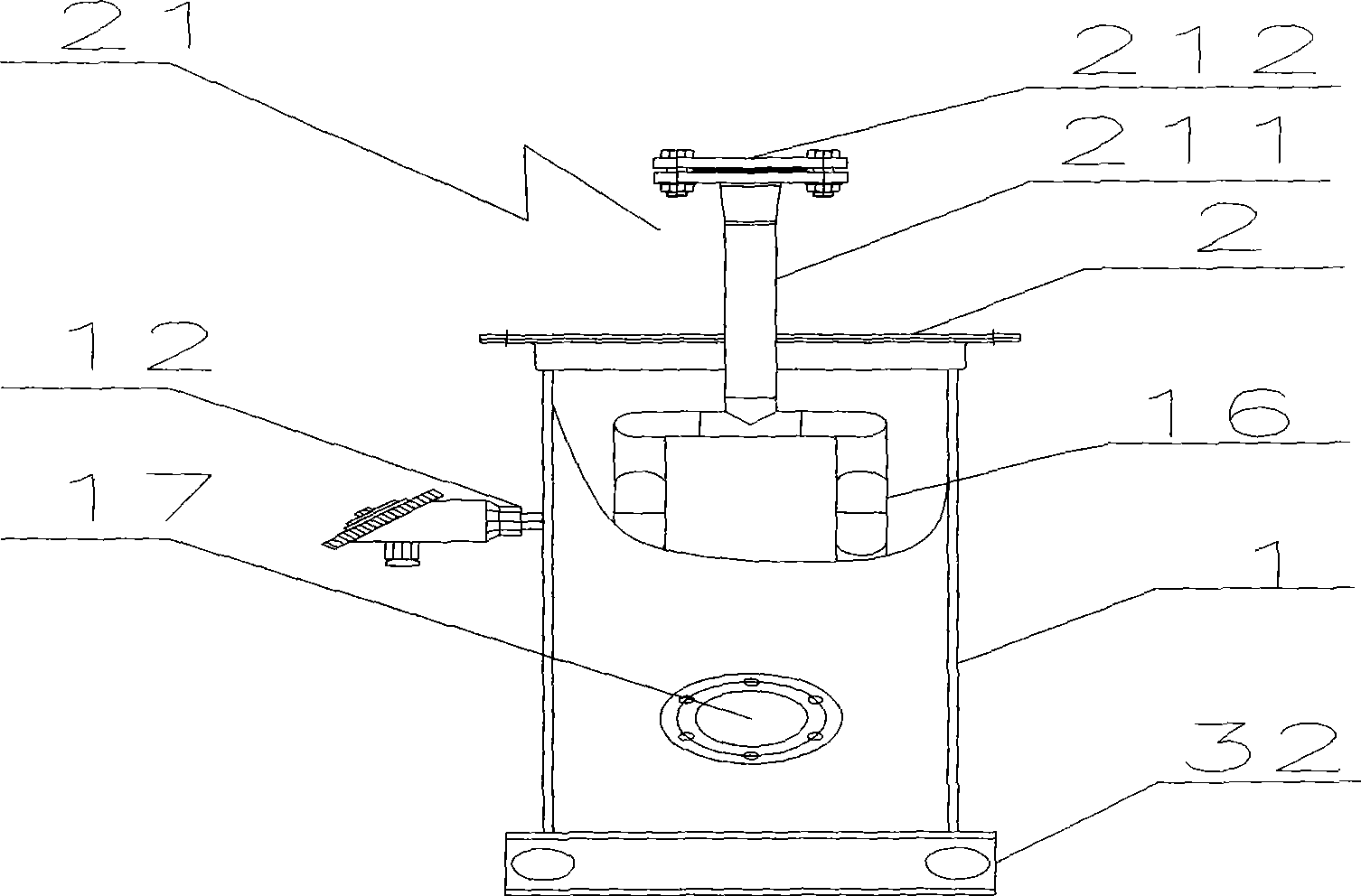

[0023] specific implementation plan

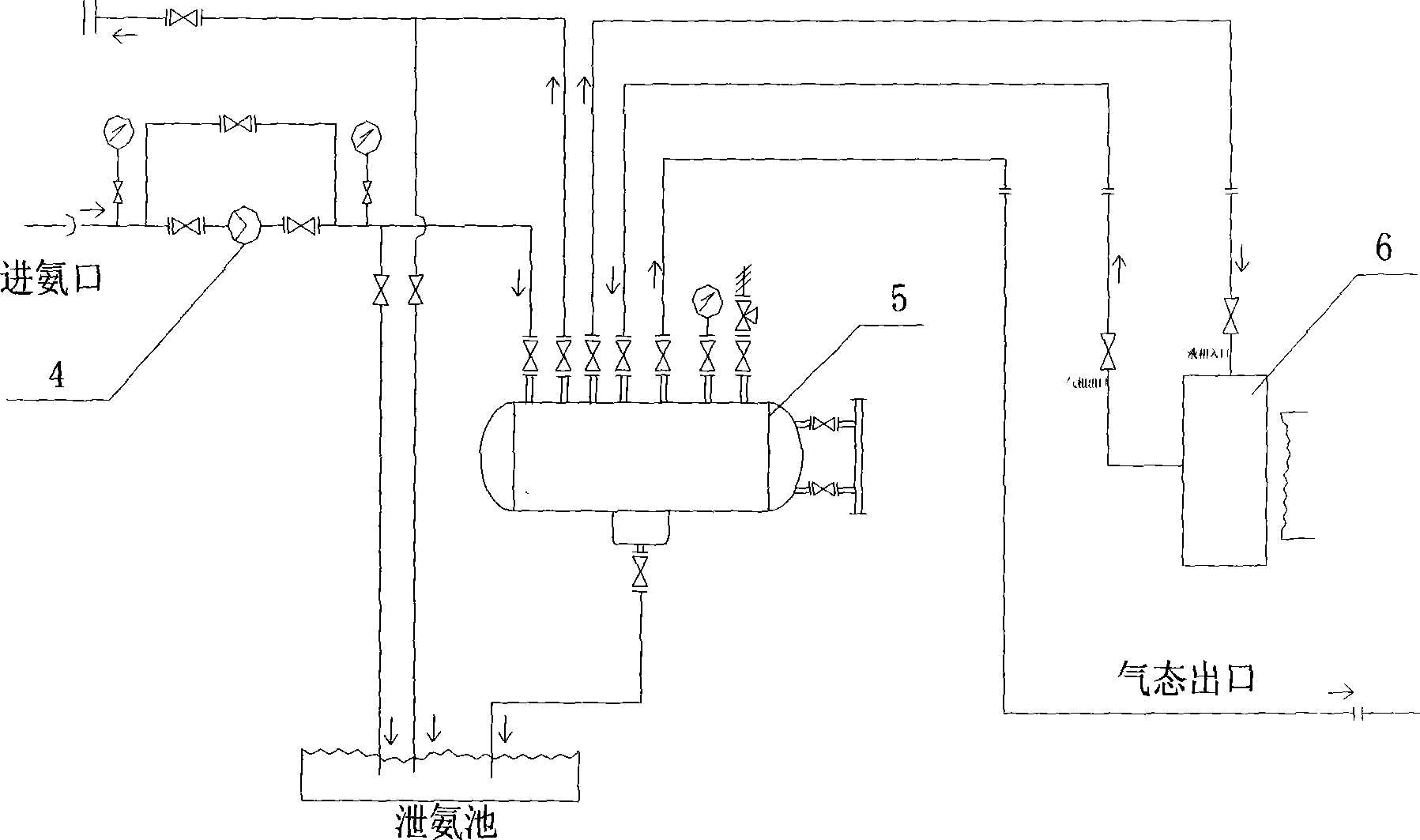

[0024] From image 3 As can be seen in the figure, a kind of ammonia circulation vaporization method, its process steps are as follows: A, the liquid ammonia of 5000kg is sent into the tank body 5 storage tanks with the ammonia pump 4 of A, external storage vehicle, can be available 100 hours as per hour consumption 50kg; B. During 100 hours of use, due to the continuous reduction of gaseous ammonia in the ammonia tank, the heat transfer area of the tank 5 is relatively small, which cannot meet the demand during use, and the pressure of the tank 5 continues to drop. The specific relationship between ambient temperature and pressure As follows: When the pressure drops to the same point of gas use, the system will lose the source of power and can no longer be transported backwards, which cannot meet the production requirements. For example, the gas point pressure is 0.1Mpa. Then at the gas point at normal temperature, the pressure is 0.1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com